Electroless Plating Automatic Liquid Replenishment Method

A liquid replenishment method and chemical plating technology, applied in liquid chemical plating, non-electric variable control, instruments, etc., can solve the problems of inability to accurately detect accurate liquid replenishment, affect luminosity, color, reduce the accuracy of liquid replenishment, etc., and achieve accurate estimation of the reaction The effect of material consumption, accurate detection and rehydration, and reduction of unstable factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

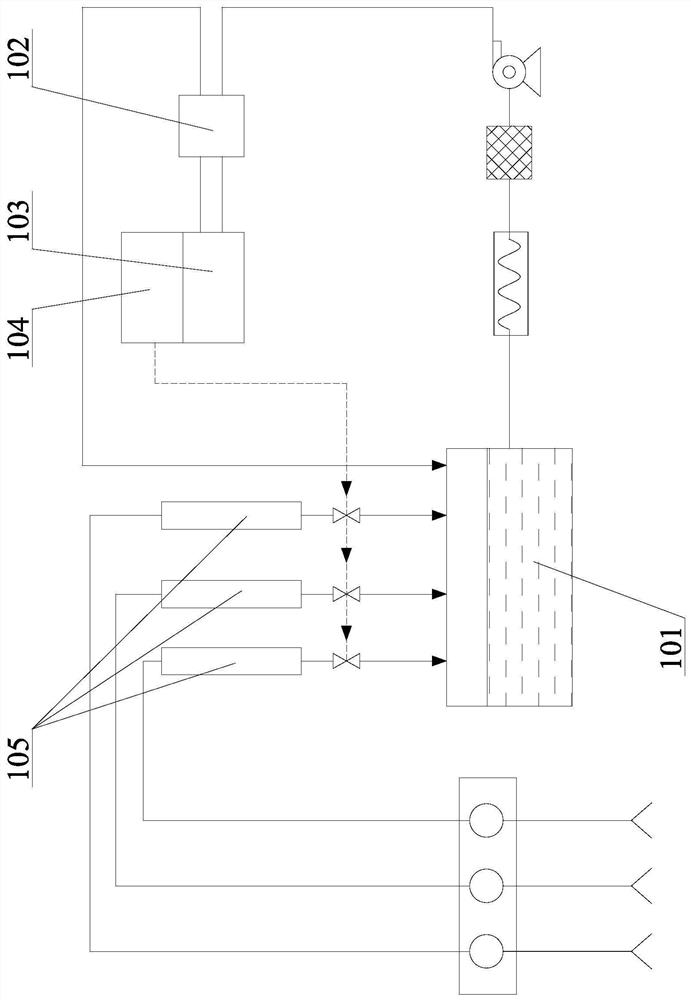

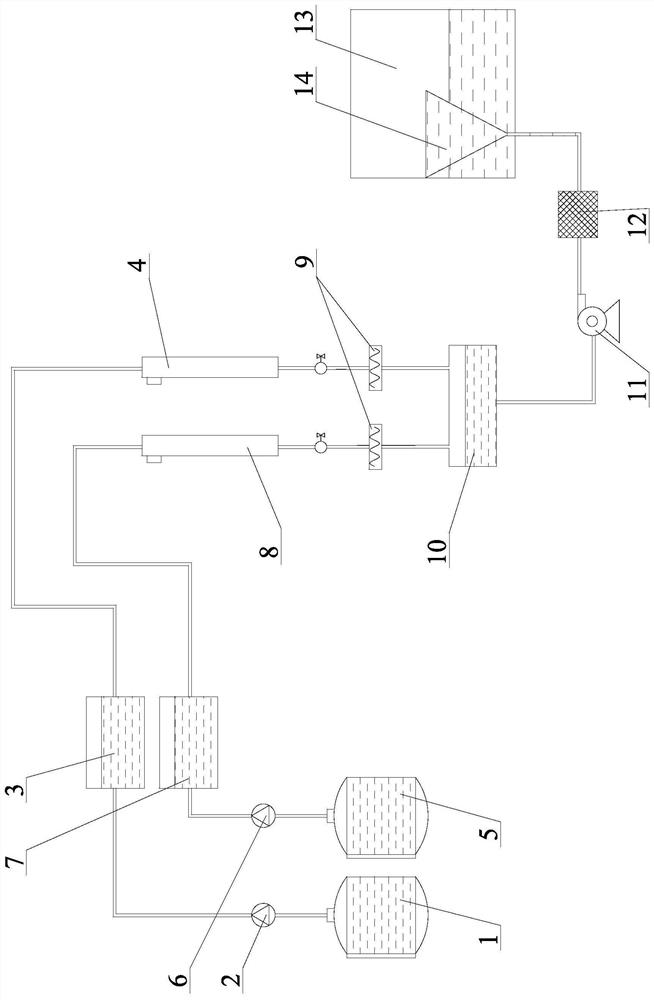

Method used

Image

Examples

example 1

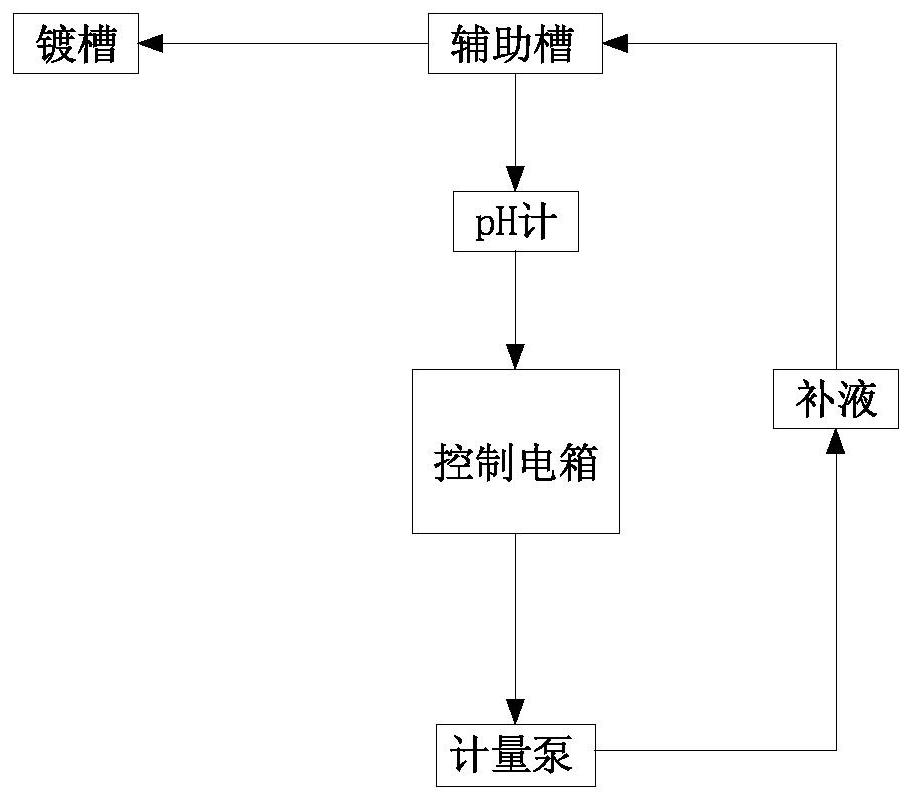

[0055] The initial pH value of the plating solution before plating is pH1=5.50, nickel sulfate concentration 16g / L, sodium hypophosphite concentration 40g / L, plating solution initial plating speed 10 μ m / h; Chemical solution A is 2mol / L sodium hydroxide solution, Chemical solution B includes 16g / L nickel sulfate and 40g / L sodium hypophosphite. The flow rate of the first metering pump is set to be 3 times of the flow rate of the second metering pump. Set the pH initial value to 4.20 in the measurement parameter interface of the control electric box panel.

[0056] During the plating process, the pH meter detects that the pH2 of the plating solution in the auxiliary tank is 4.10. The metering pump starts to work. The first metering pump pumps the liquid A, that is, the sodium hydroxide solution enters the plating tank from the auxiliary tank after preheating; at the same time, the second metering pump pumps the liquid B. After the liquid B is preheated, Enter the plating tank ...

example 2

[0058] The initial pH value of the plating solution before plating is pH1=8.50, the concentration of nickel sulfate is 30g / L, the concentration of sodium hypophosphite is 35g / L, and the initial plating speed of the plating solution is 20 μm / h; the liquid A is 2mol / L sulfuric acid solution, and the liquid B includes 30g / L nickel sulfate and 35g / L sodium hypophosphite. The flow rate of the first metering pump is set to be 4 times of the flow rate of the second metering pump. Set the pH initial value to 10.50 in the measurement parameter interface of the control electric box panel.

[0059] During the plating process, the pH meter detects that the pH2 of the plating solution in the auxiliary tank is 10.65. The metering pump starts to work. The first metering pump pumps the liquid A, that is, the sulfuric acid solution enters the plating tank from the auxiliary tank after preheating; at the same time, the second metering pump pumps the liquid B for adjusting the composition of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com