Food waste processor and installation method thereof

A food waste treatment and driver technology, which is applied to water supply installations, indoor sanitary piping installations, buildings, etc., can solve the problems of always-open water outlet, large vibration of grinding chamber, difficult disassembly and installation, etc., avoiding the operation of screwing , Reduce the probability of loosening, the effect of convenient disassembly and assembly of the connecting seat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

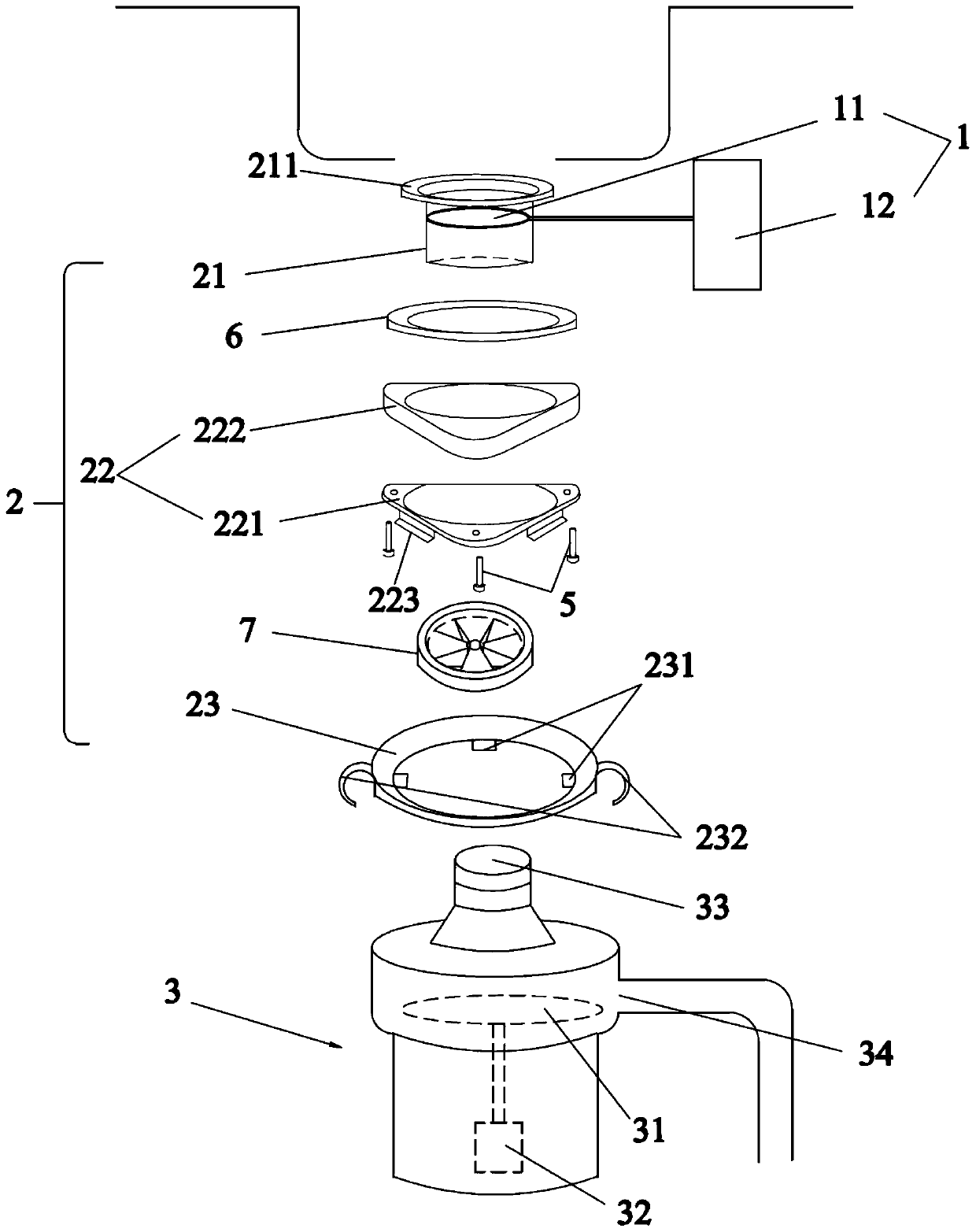

[0028] Such as figure 1As shown, a food waste disposer includes a filter assembly 1, a connecting part 2 and a crushing chamber 3. The connecting assembly 2 includes a drain pipe 21, a connecting seat 22 and a connecting ring 23. The connecting seat 22 is sleeved on the drain pipe 21, The filter assembly 1 is used to open or close the downpipe 21 , the pulverizing chamber 3 is connected to the downpipe 21 , one end of the connecting ring 23 is detachably connected to the connecting seat 22 , and the other end of the connecting ring 23 is fixed to the pulverizing chamber 3 . The connecting part 2 and the crushing chamber 3 are successively installed under the water outlet of the water tank, and the connecting seat 22 is sleeved on the sewer pipe 21. This connection method avoids the operation of screwing when disassembling and assembling the garbage disposer, so that the disassembling and assembling of the connecting seat 22 It is more convenient; the filter assembly 1 can be i...

Embodiment 2

[0038] Such as figure 1 Shown, the installation method of a kind of food waste disposer described in embodiment 1, comprises the steps:

[0039] The valve 11 is installed on the water inlet of the downpipe 21, and the output end of the driver 12 is connected to the valve 11 through the downpipe 21 to ensure that the filter assembly 1 can open or close the downpipe 21;

[0040] The connecting seat 22 is sleeved on the downpipe 21, and the shock absorber 6 is installed between the flange 211 and the connecting seat 22, and the splash ring 7 is installed between the connecting seat 22 and the connecting ring 23, and then the connecting ring 23 It is fixed on the bottom of the connecting seat 22 through the fastener 231;

[0041] The crushing chamber 3 is fixed to the lug 232 of the connecting ring 23 to ensure that the crushing chamber 3 communicates with the drain pipe 21 .

[0042] It should also be noted that: in the installation method of the present invention, the filter a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com