Mechanical reversing wall touching testing mechanism of pool cleaning machine

A technology of mechanical commutation and detection mechanism, applied in swimming pools, geophysical measurements, moving filter element filters, etc., can solve the problems of hindering the movement of the cleaning machine, unable to use cables, and loss of efficiency, and achieves compact structure, production and production. Low cost and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

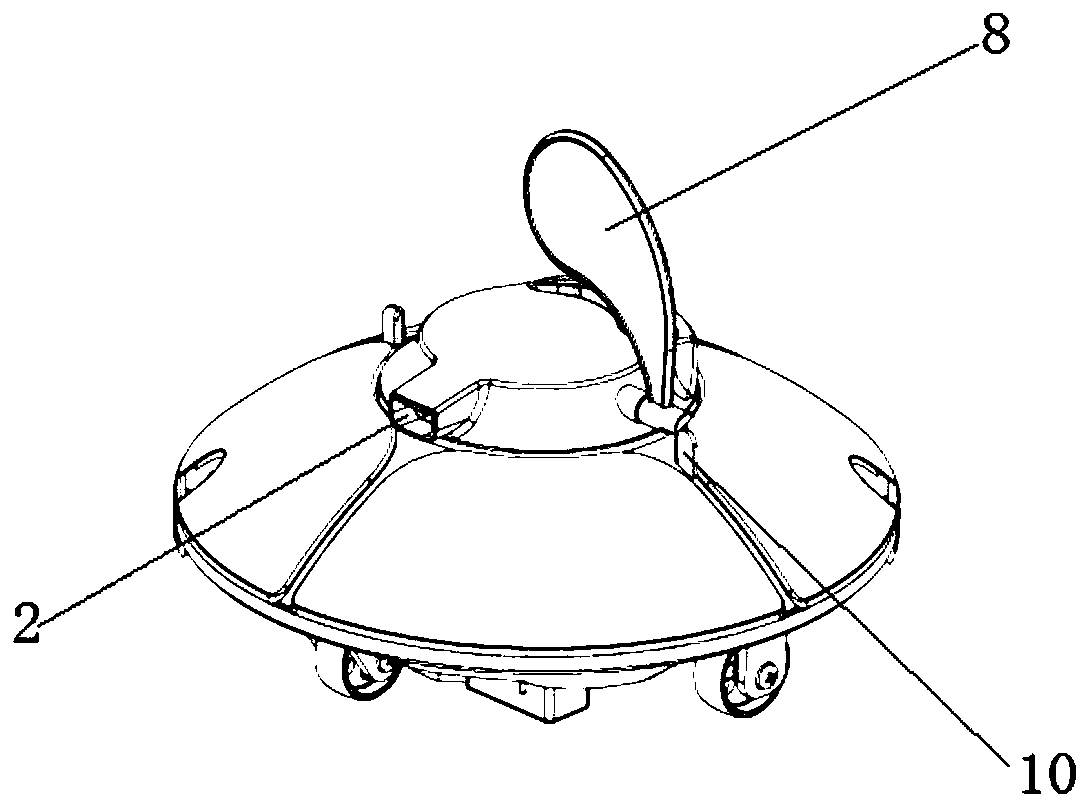

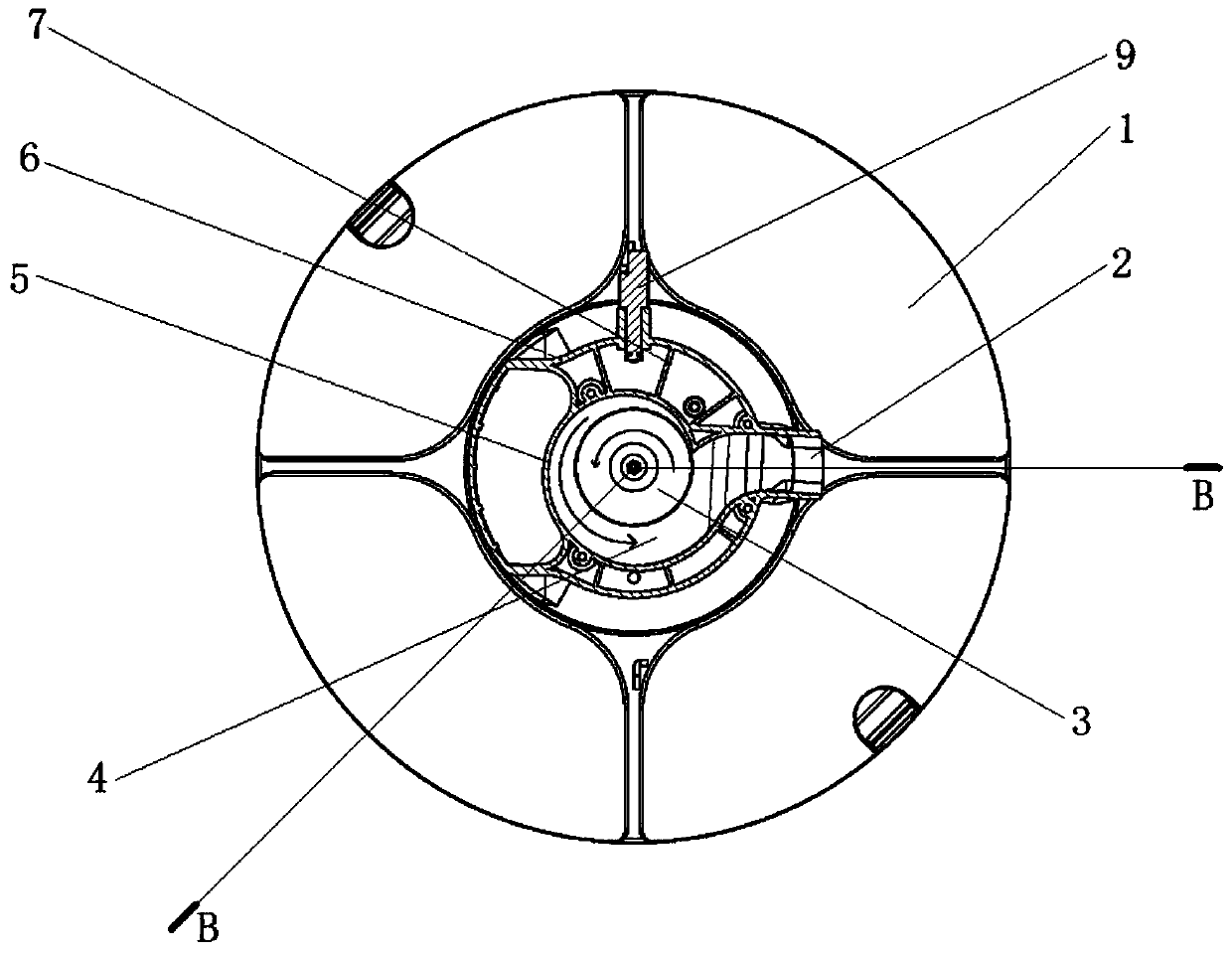

[0060]The mechanical reversing wall contact detection mechanism of the pool cleaning machine includes a power part non-rotatably connected to the cleaning machine housing, a stop assembly 10 and a rotation reversing assembly, and the rotation reversing assembly is rotatably connected to the cleaning machine housing 1 or the power part , the stop assembly 10 is connected with the cleaning machine housing 1, and the stop assembly 10 cooperates with the rotation reversing assembly. Through the action of the power part, the rotation and reversing assembly is driven to provide power for the rotation and reversing assembly to realize the rotation conversion. The direction assembly and the suction assembly rotate in the same direction to realize the cooperation between the rotation reversing assembly and the stopper assembly 10, and through the cooperation of the stopper assembly 10 and the rotation reversing assembly, the wall-touching reversing is realized when the cleaning machine t...

Embodiment 2

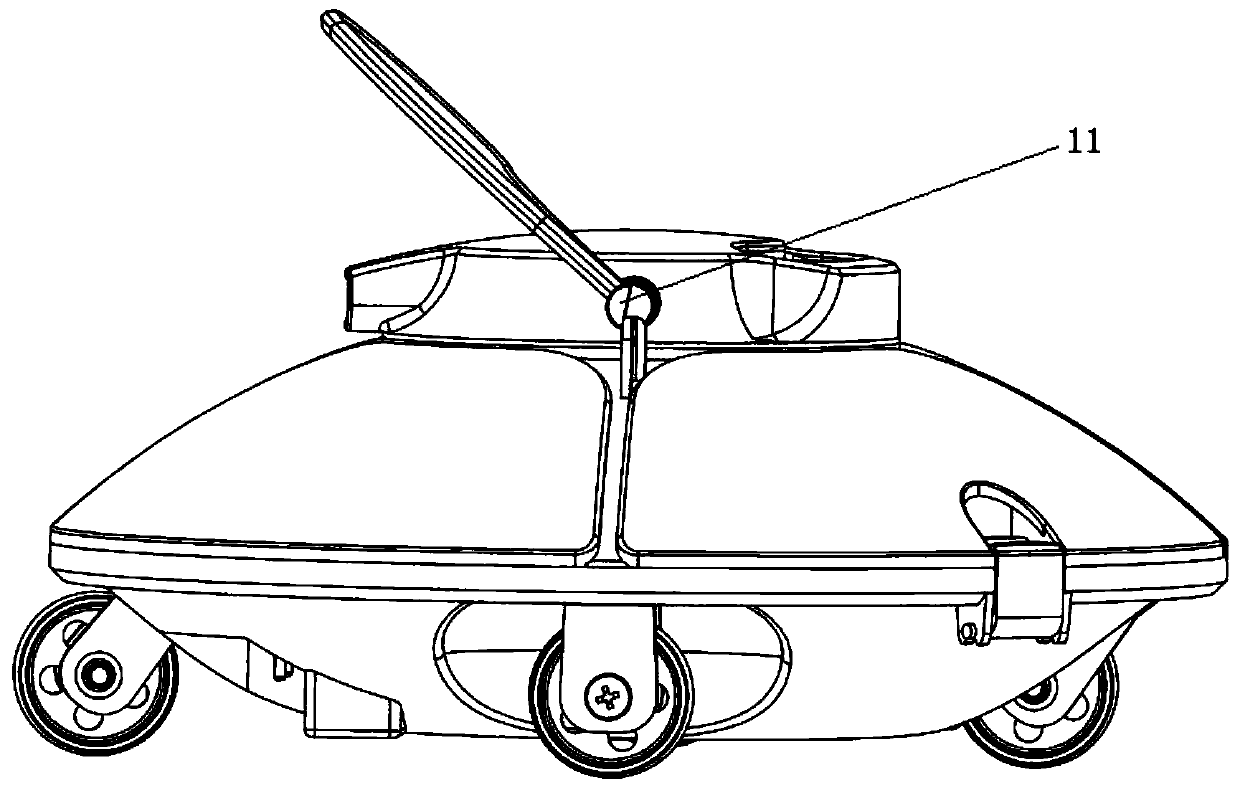

[0090] The present embodiment is compared with implementing benefit one, as Figure 9-12 As shown, the difference is that the sealing device is fixedly installed on the cleaning machine housing 1, and the sealing device is located outside the cleaning machine housing 1, fixedly installed on the top of the cleaning machine housing 1, and the power drive device 13 is fixedly installed on the sealing Inside the device, and the drive shaft of the power drive unit 13 stretches out of the sealing device, the connection between the drive shaft and the sealing device is sealed by a seal to prevent water from entering the inside of the sealing device and causing damage to the power drive unit 13. When the power drive device 13 is installed, it is vertically inverted, the drive shaft of the power drive device 13 is located at the bottom of the sealing device, the suction assembly 3 is fixedly installed on the drive shaft of the power drive device 13, and one end of the rotary reversing a...

Embodiment 3

[0101] The difference between this embodiment and Embodiment 1 and Embodiment 2 is that in this embodiment, a magnetic coupling method is used to transmit the torque of the suction assembly, while Embodiment 1 and Embodiment 2 use hydraulic force The coupling mode is used to transmit the torque of the suction assembly, wherein the structure of the reversing assembly and the stop assembly 10 is the same as that of Embodiment 1 and Embodiment 2, and the structure of the reversing assembly and the suction assembly is the same as that of Embodiment 1 and Embodiment 1. The two structures are the same. The difference is that if Figure 19 , 21 As shown in 22 and 22, the mechanical reversing wall contact detection mechanism of the pool cleaning machine also includes a magnetic coupling assembly, which is connected to the suction assembly 3 and the rotating assembly respectively, and the suction assembly 3 and the rotation assembly are realized through the magnetic coupling between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com