Water power pulse wave injection increasing device

A hydraulic pulse and pulse technology, which is applied in the direction of cleaning equipment, production fluid, wellbore/well components, etc., can solve the problems of short validity period of plugging and injection increase, and achieve enhanced oil recovery, convenient operation and reasonable structural design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

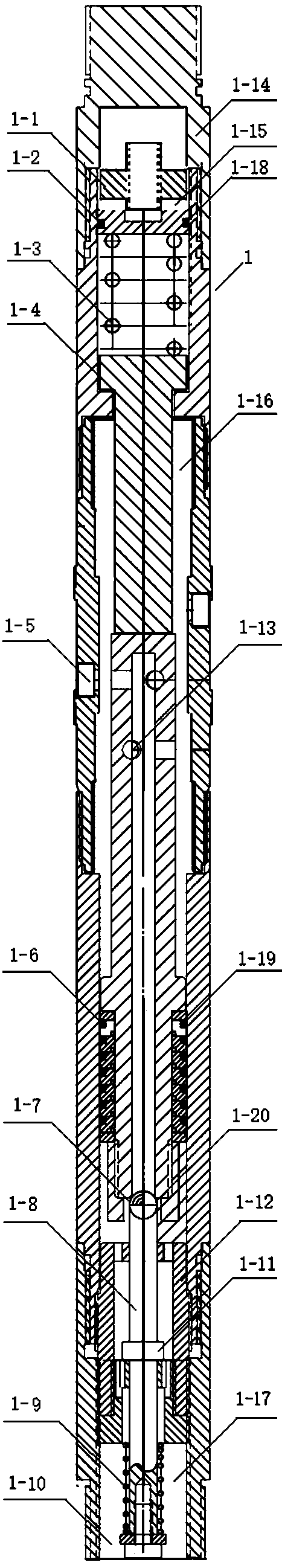

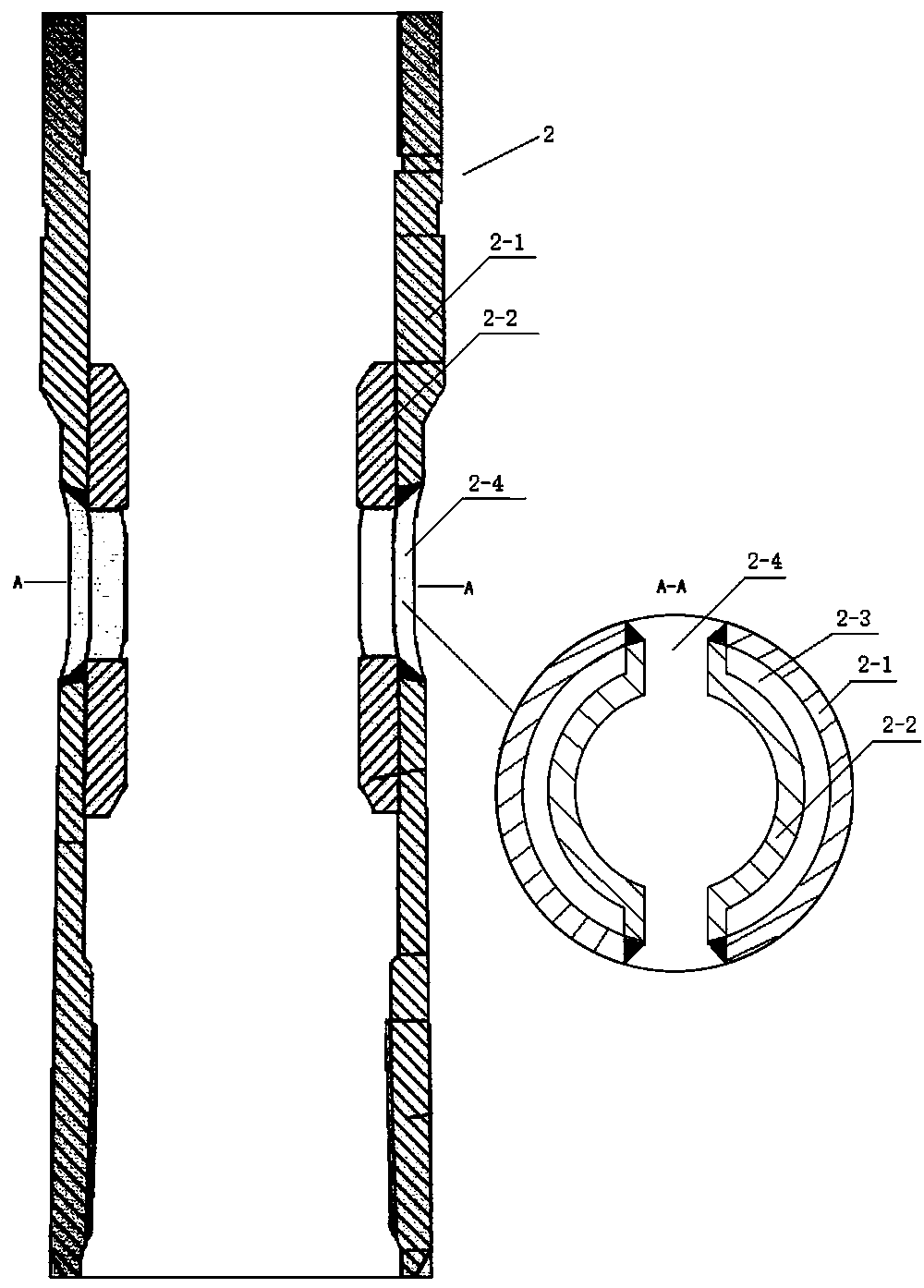

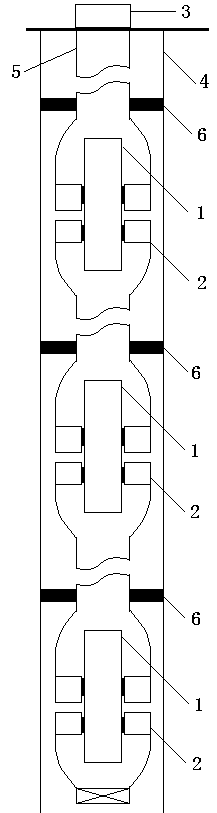

[0040] Refer to attached Figure 1-3 , a hydraulic pulse wave injection device is composed of a working cylinder 2 and a hydraulic pulse wave injection device 1; the hydraulic pulse wave injection device 1 is installed in the working cylinder 2. The hydraulic pulse wave injector is installed and inserted in the sealed work cylinder 2 . The working cylinder 2 plays the role of layer separation and sealing in the whole pulse wave water injection operation. There is a sealing ring between the hydraulic pulse wave injector 1 and the working cylinder 2. The hydraulic pulse wave injector 1 and the working cylinder 2 are sealed and matched to establish two water injection channels. The bridge channel 2-3 makes the water flow from the hydraulic pulse wave The upper part of the injector flows to the lower part of the water flow channel. The water outlet 2-4 of the working cylinder allows the water flow to flow from the inside of the hydraulic pulse wave injector 1 into the water flow...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap