Oil and gas well filling sand control method and equipment

A technology for oil and gas wells and sand control, used in earth-moving drilling, flushing wellbore, wellbore/well components, etc., can solve problems such as low permeability, liquid loss, formation pollution, etc., to avoid pollution and damage, and ensure permeability. , the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with specific examples, but not as a limitation of the present invention.

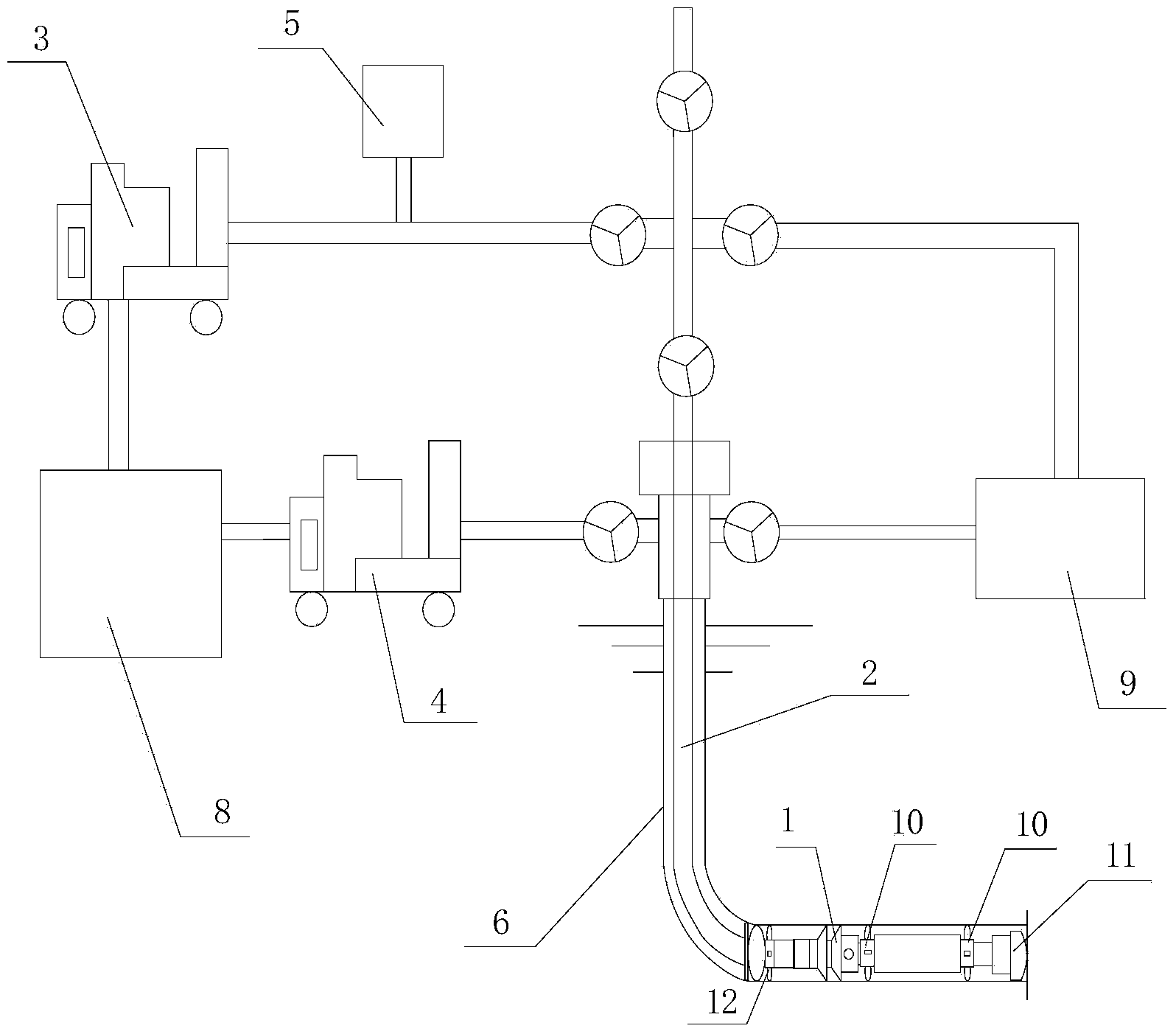

[0029] The oil and gas well filling sand control method includes the following steps:

[0030] (1) Drilling, the drilled drill bit is used for the drilling of the open hole section, and the drilling gauge of the same diameter is used for the drilling of the well in the casing.

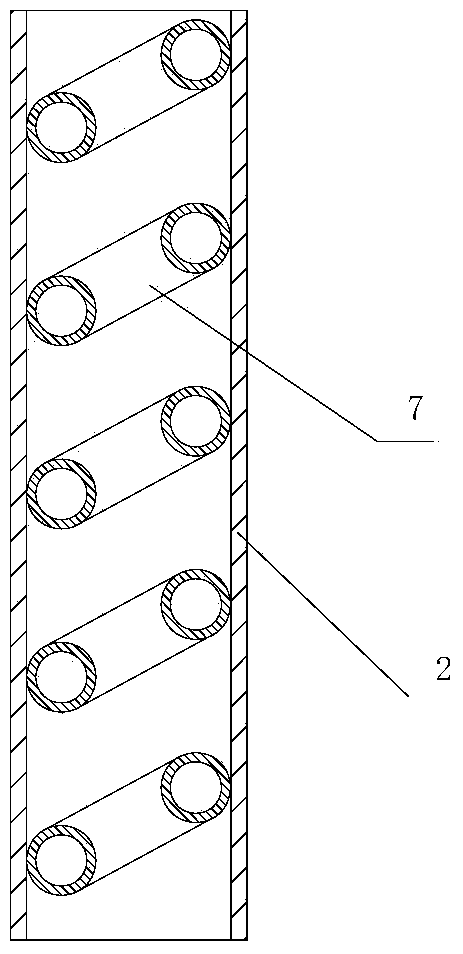

[0031] (2) Lower filling manifold, openhole screen completion filling first lowers the completion manifold, and then lowers the filling manifold; filling in the casing is directly lowered into the filling manifold. Packing manifolds include transfer strings and packing tools. The filling tools include hands-free or plug-in filling tools, that is, the transfer string and the filling tool are connected or plugged in.

[0032] (3) Well flushing, using gas or foam as the circulating medium for circulating well flushing, including cleaning the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com