A method for controlling the system pressure of a centrifugal air compressor station

A system pressure and control method technology, applied in pump control, non-variable pumps, machines/engines, etc., can solve problems such as waste of air release, untimely response, large fluctuations in system pressure, etc., to maintain system pressure stability, Avoid invalid output and reduce the effect of system pressure fluctuation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

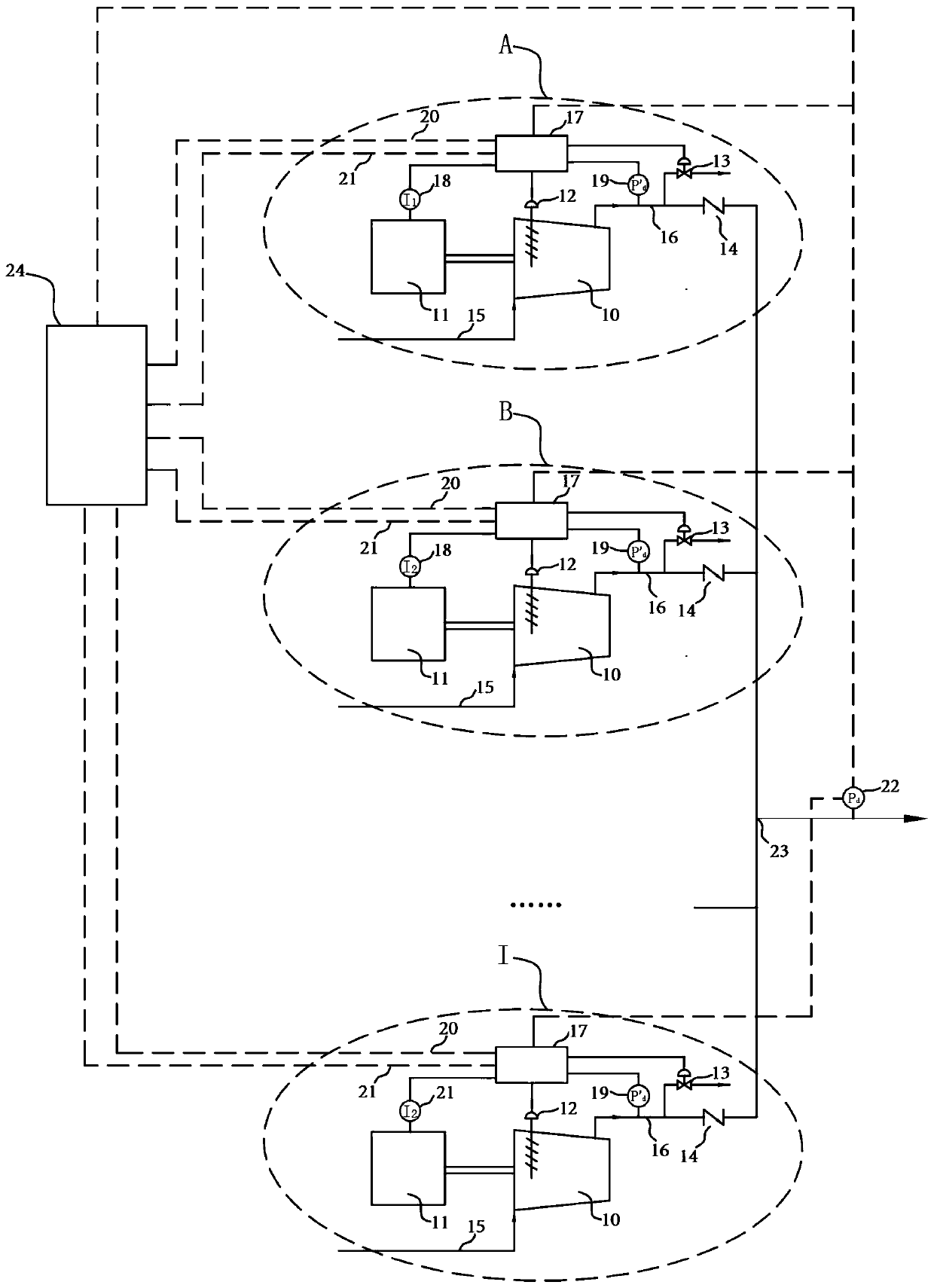

[0032] Example: as attached figure 1 Shown is the model diagram of the compression system of multiple centrifugal air compressors connected in parallel in the present invention, and the shown parallel connection compressor units A, B, ..., I are controlled by the centralized control system 24 and the on-site PLC of each compressor unit Station 17 is controlled, wherein the capacity of some compressor units may be different, but the structure of each compressor unit is the same (in this embodiment, all take the form of motor-driven compressors as an example), and have the same composition. One compressor unit includes an on-site PLC control station 17. Compressor body 10, drive motor 11, current sensor 18, exhaust branch pipe 16, exhaust valve 13, check valve 14 and branch pipe pressure sensor 19, the output end of the drive motor 11 is connected to the compressor body 10, and the The current sensor 18 is connected to the driving motor 11, the suction side of the compressor bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com