Speed reducer

A technology of reducer and casing, applied in the direction of transmission parts, components with teeth, belt/chain/gear, etc., can solve the problems of large shaking of the reducer, loud noise of the reducer, etc., to avoid noise and strengthen the seal. effect, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

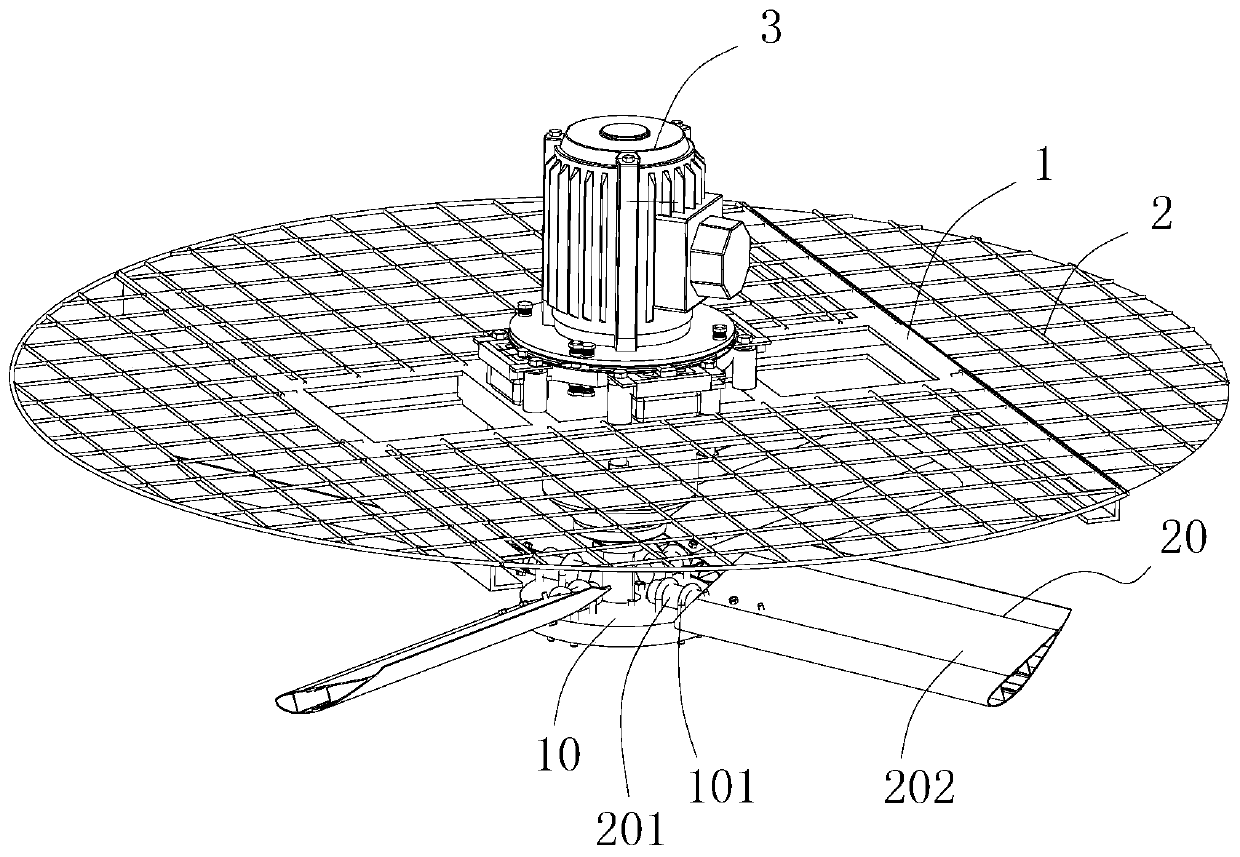

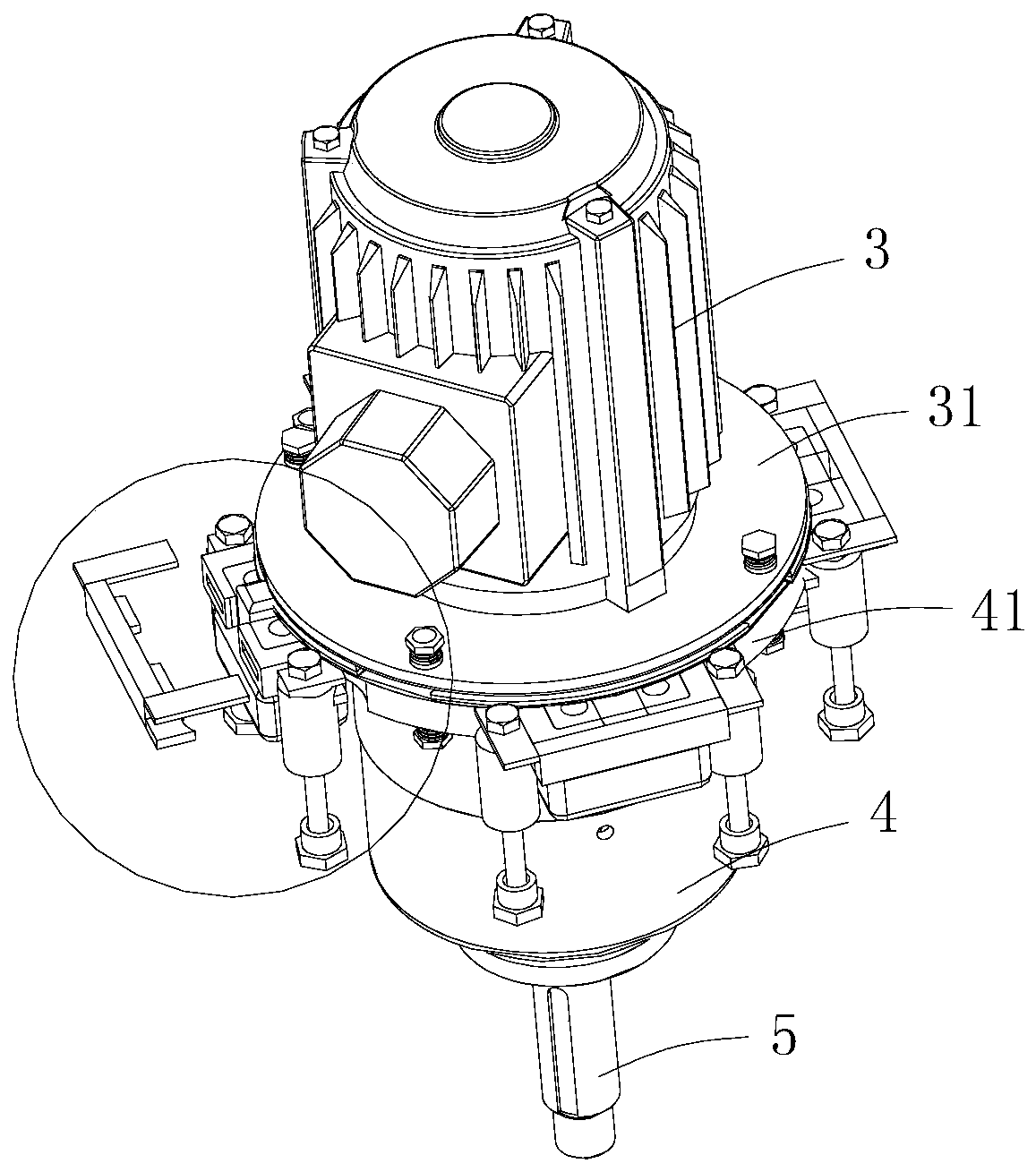

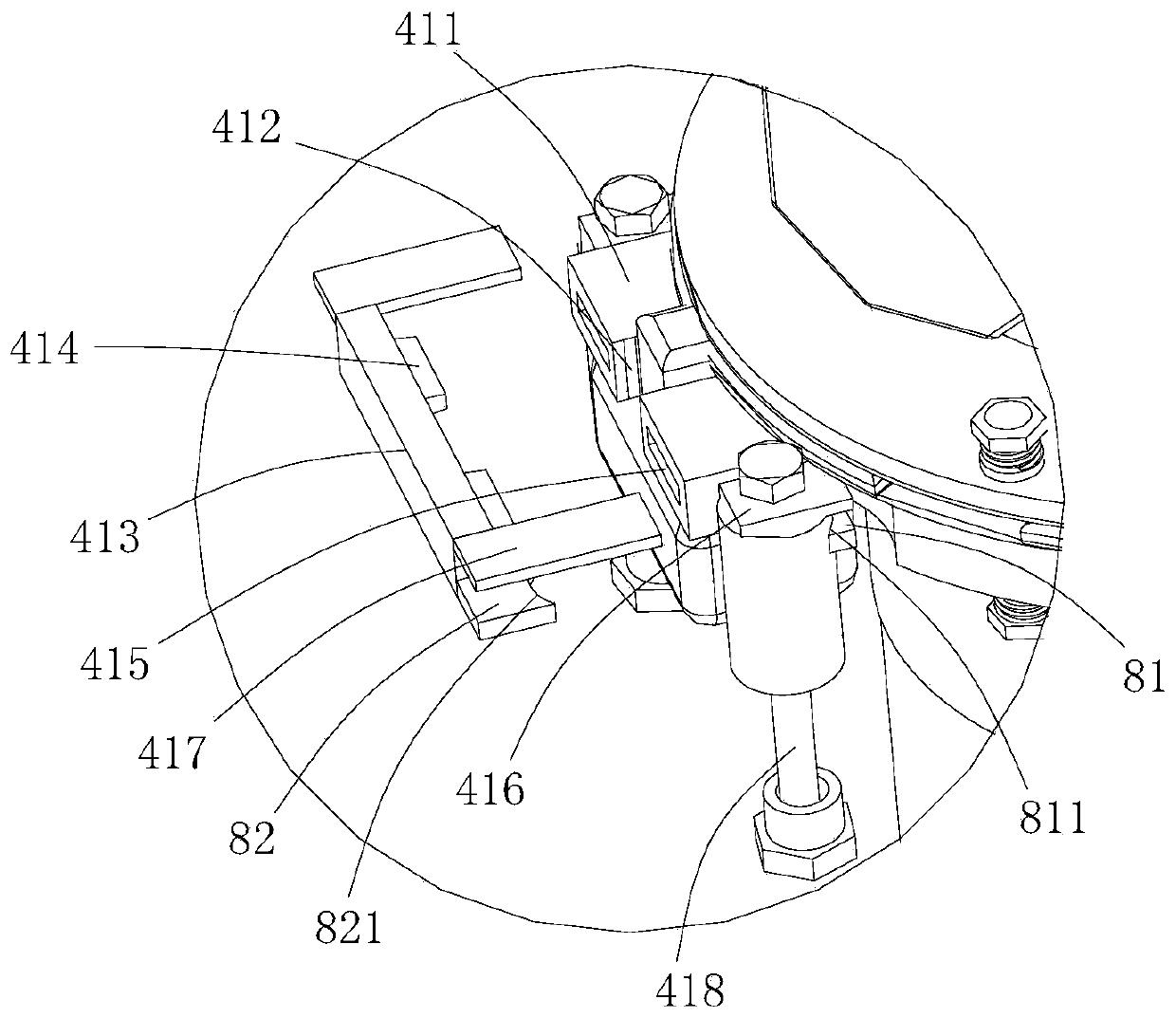

[0029] Such as Figure 1-9 As shown, a reducer is arranged on a cooling tower, and the output shaft of the reducer is connected with a fan. The upper part of the cooling tower is provided with a support 1 and a wire mesh 2, and the reducer is arranged on the support 1 ; Including the upper casing 3 and the lower casing 4; the output shaft 5 is arranged on the lower casing 4; the connecting device is used to limit and fix the reducer to the support frame 1; the shock-absorbing seal 6 has a sealing part 61. A shock-absorbing portion 62 and a connecting portion 63 for connecting the shock-absorbing portion and the sealing portion. The sealing portion 61 is placed at the connection of the upper and lower casings, and the upper and lower surfaces are respectively sealed and matched with the upper and lower casings; the shock-absorbing portion 62 is provided between the lower casing 4 and the support frame 1, and is used to realize the shock absorption operation of the reducer; the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com