Cloth drying device used for textile processing

A technology for drying fabrics and textiles, applied in textiles and papermaking, drying, dryers, etc., can solve the problems of breeding bacteria, affecting the normal use requirements of textile processing, and easy wrinkling or folding of fabrics, so as to improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

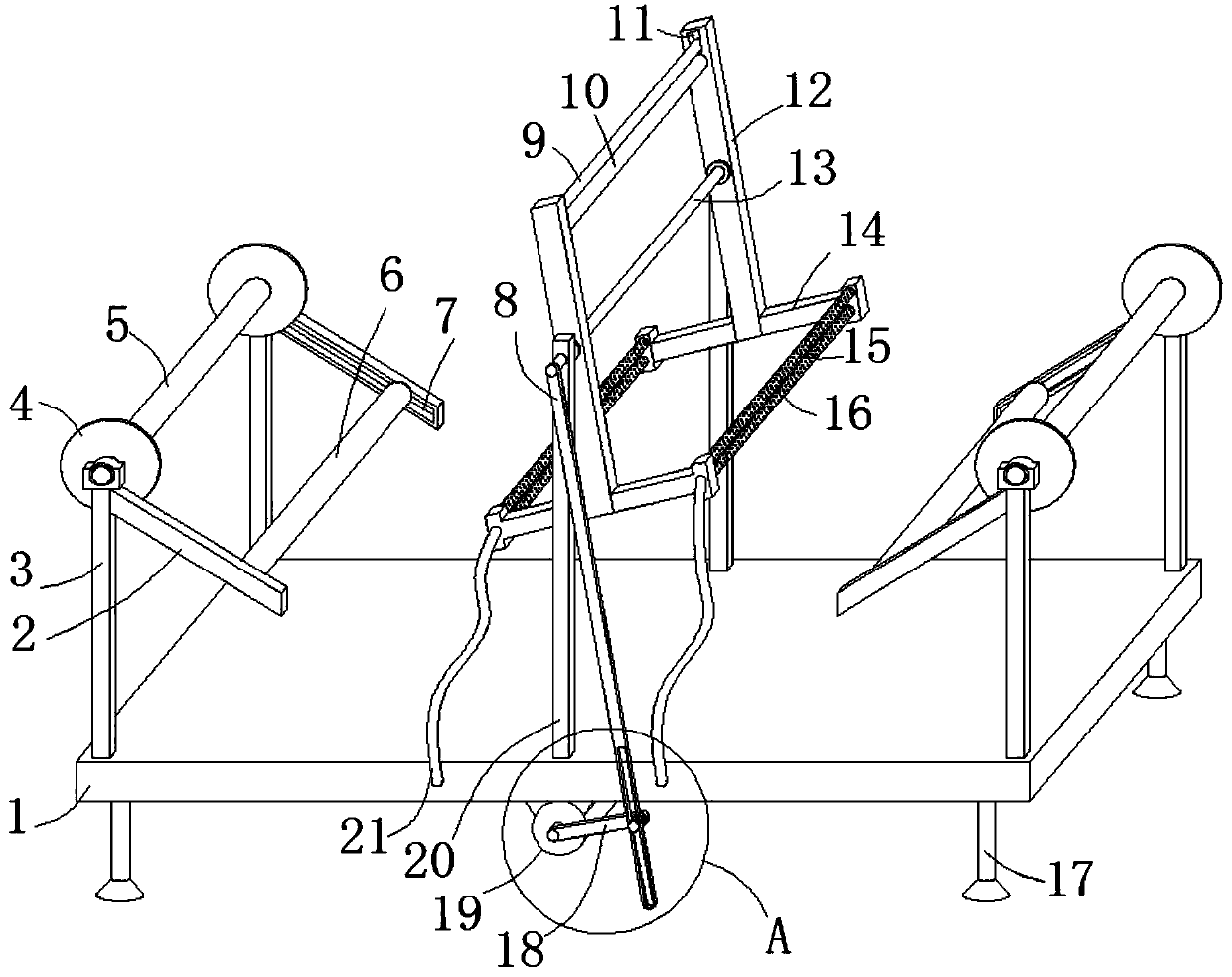

[0024] see Figure 1-4 , the present embodiment provides a cloth drying device for textile processing, including a base 1, the left and right sides of the top surface of the base 1 are vertically welded with front and back symmetrical support columns 3, and the tops of the left two support columns 3 and the The tops of the two support columns 3 on the right are rotated and plugged with guide rollers 5, the top right sides of the two support columns 3 on the left side and the top left sides of the two support columns 3 on the right are all inclined downward and welded with guide rods 2. The opposite side walls of the two guide rods 2 on the left side and the opposite side walls of the right guide rod 2 are provided with chute 7, and the weight roller 6 is slidingly clamped through the chute 7, and the front and rear sides of the middle section of the top surface of the base 1 A support rod 20 is vertically welded, and a transmission roller 13 is inserted and rotated between the...

Embodiment 2

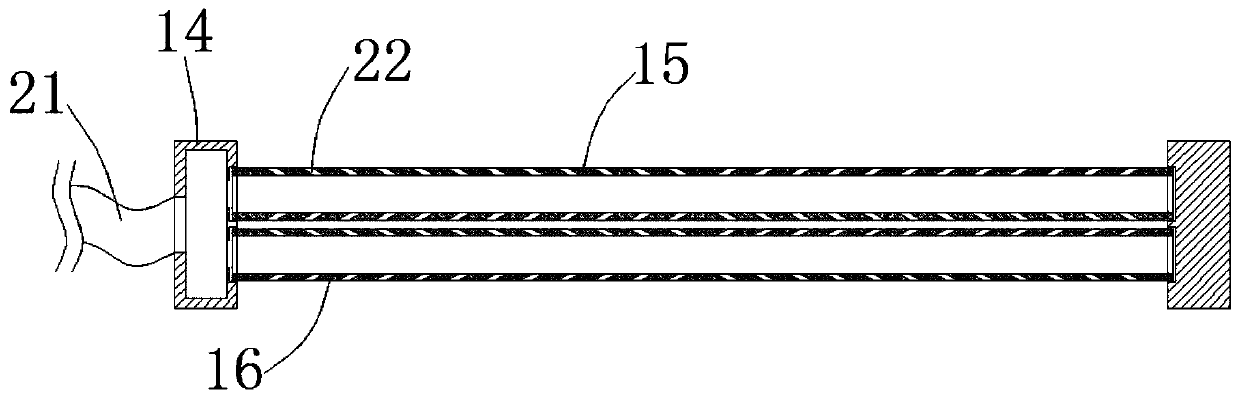

[0028] see Figure 1-4On the basis of Embodiment 1, a further improvement is made: the angle between the guide rod 2 and the horizontal plane is 45 degrees, which facilitates the guide roller 5 to slide in the inner cavity of the chute 7 to achieve the purpose of tensioning the cloth. The inner cavity length of the waist-shaped hole 24 is equal to 2.2 times of the length of the connecting rod 18, which is convenient for the connecting rod 18 to do circular motion, thereby driving the purpose of the hinged rod 8 to swing left and right. Vertically distributed lifting grooves 11, and between the two lifting grooves 11, there is a counterweight roller 9 that can slide up and down in the cavity of the lifting groove 11. The weight roller 9 is located above the ironing column 10. By setting the weight roller 9. It is convenient to tightly fit the cloth to the ironing column 10, and achieve a good ironing and drying effect. The air outlets 22 of the first air supply cylinder 15 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com