Radio frequency performance test fixture for BGA package product

A technology for testing fixtures and RF performance, which is used in measurement devices, transmitter monitoring, and measurement of electrical variables to achieve the effects of accurate alignment, fast device installation, and stable electrical connections.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

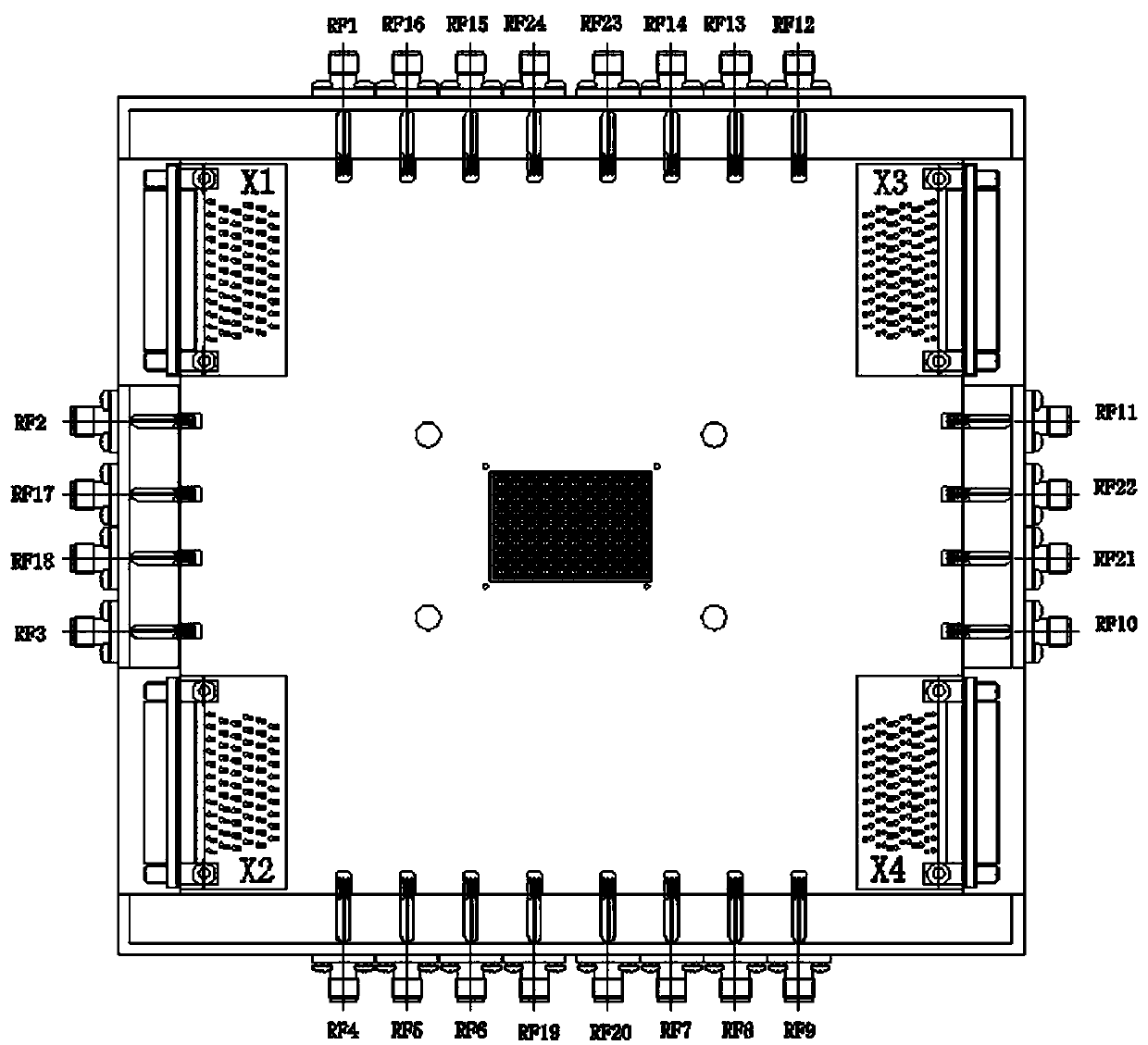

[0036] A BGA packaging product radio frequency performance test fixture, the test fixture includes a test fixture base plate, a pressurization mechanism, a positioning mechanism, a test motherboard and an elastic diaphragm, and the pressurization mechanism, positioning mechanism, test motherboard and elastic diaphragm are all arranged on The same side of the bottom plate of the test fixture; the pressurizing mechanism is set on the bottom plate of the test fixture to pressurize the BGA package product to be tested, the test motherboard is set between the bottom plate of the test fixture and the pressurizing mechanism, and the elastic diaphragm is placed on the test mother BGA pad side of the board; as Figure 6 As shown, when the BGA package product to be tested is not pressurized by the pressurization mechanism, there is a gap between the BGA ball, the elastic diaphragm, and the BGA pad of the test motherboard of the BGA package product, and there is no conduction. After the ...

Embodiment 2

[0056] A BGA packaging product radio frequency performance test fixture, such as Figure 3-5 As shown, it includes the bottom plate of the test fixture, the pressurization mechanism, the positioning mechanism, the test motherboard, the elastic diaphragm and the limit washer.

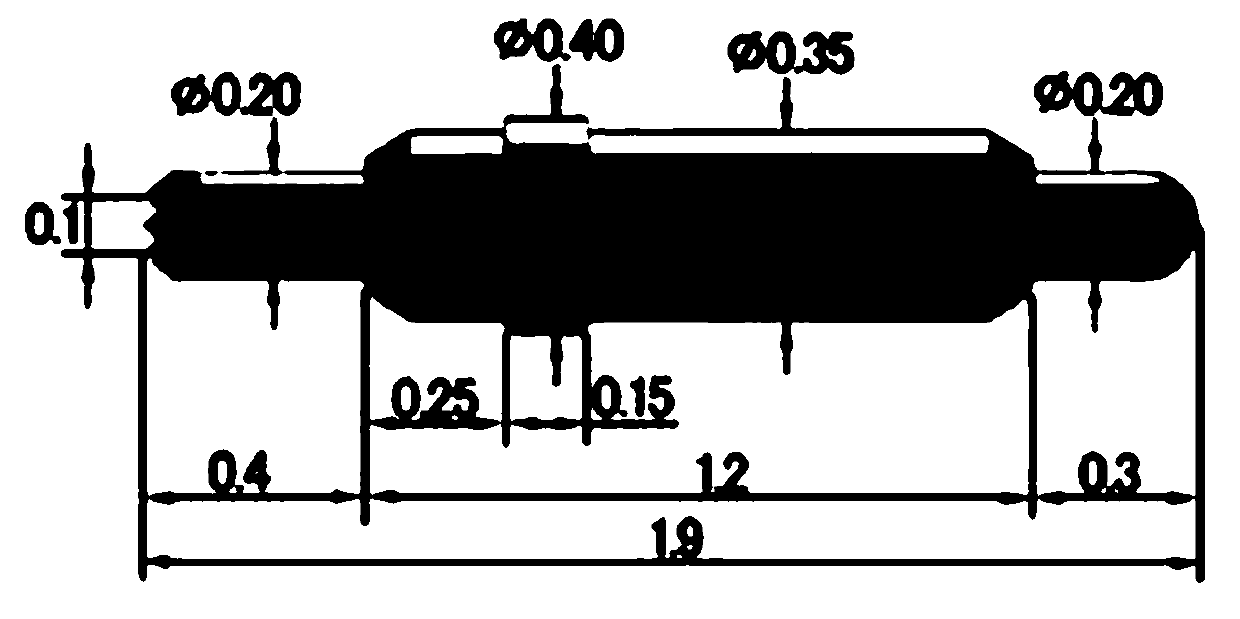

[0057] The manufacturing process of the elastic diaphragm is as follows:

[0058] (1) Gold-plate the surface of the wire to obtain a conductive wire with coating protection;

[0059] (2) Weave metal wire and fiber wire (insulation, such as polyester) in the warp and weft directions to obtain a two-dimensional unidirectional conductive wire mesh;

[0060] (3) Arrange the wire mesh and the silica gel sheet into several layers according to the interval, and pre-fix them with clamps, and keep the direction of the wires consistent during the arrangement process;

[0061] (4) Heat and pressurize the laminated structure, so that the metal wire and the insulating medium are closely bonded to obtain a unidirect...

Embodiment 3

[0072] This embodiment discloses a jig for testing the radio frequency performance of a BGA package product, comprising the following steps:

[0073] A. Install the positioning mechanism, the limit gasket and the pressurizing mechanism in sequence;

[0074] B. Place the BGA package product to be tested in the positioning mechanism;

[0075] C. Adjust the pressurization mechanism in the direction of pressurization until the elastic diaphragm conducts radio frequency;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com