A system and method for online detection of working junction temperature of igbt module

A technology of working junction temperature and detection system, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve problems such as power consumption and high chip junction temperature, high-power converter system failure, IGBT damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

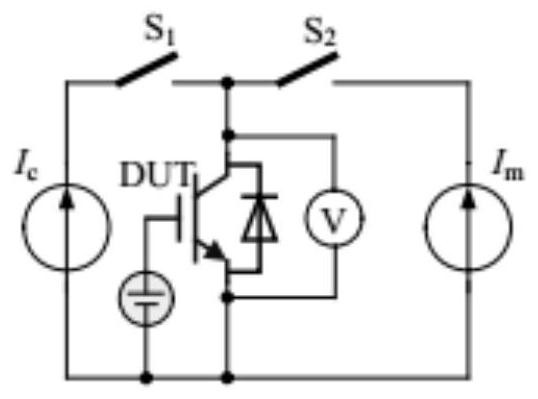

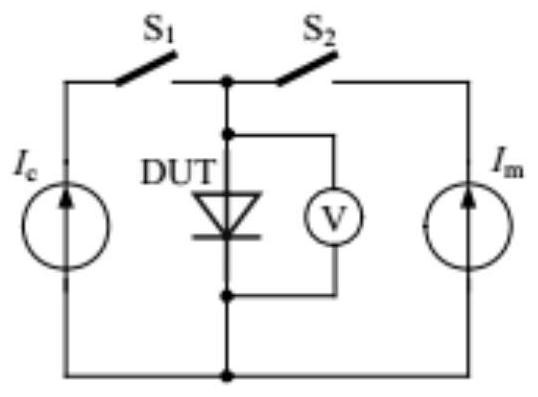

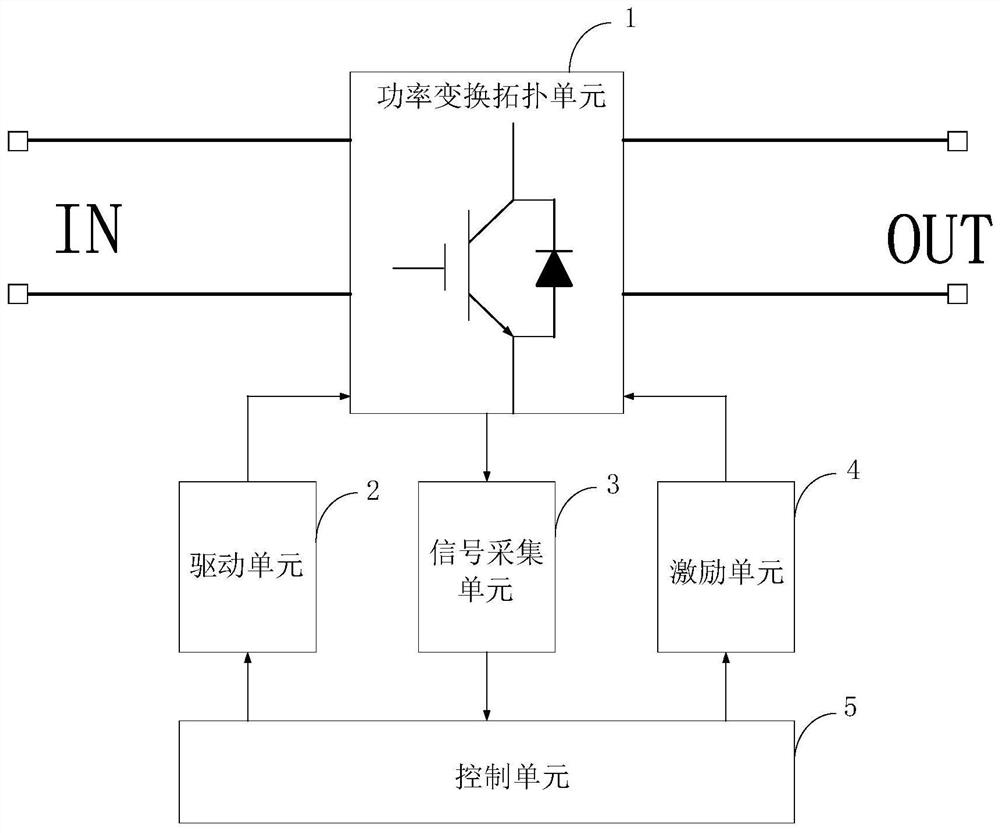

[0047] As mentioned in the background technology, in the high-power converter system, the operating voltage and current of the power module IGBT are relatively high, which leads to high power consumption and high chip junction temperature. Once the temperature is too high, the IGBT will be damaged, which will lead to High power converter system failure.

[0048] Therefore, it is necessary to detect the working junction temperature of the IGBT module. Commonly used IGBT module working junction temperature detection methods include:

[0049] ①Physical contact measurement method:

[0050]Use temperature measuring elements such as thermistors or thermocouples to measure the internal ambient temperature or external case temperature of the IGBT module. However, the temperature measurement point in this method is generally at a certain distance from the IGBT module, resulting in large measurement errors. In addition, the response speed of temperature measurement is slow (second le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com