Waste recovering device

A technology of waste recycling and waste collection, which is applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of increasing the work intensity of staff and increasing time costs, and achieve saving time costs and labor costs, Improvement of effect, effect of improving waste collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

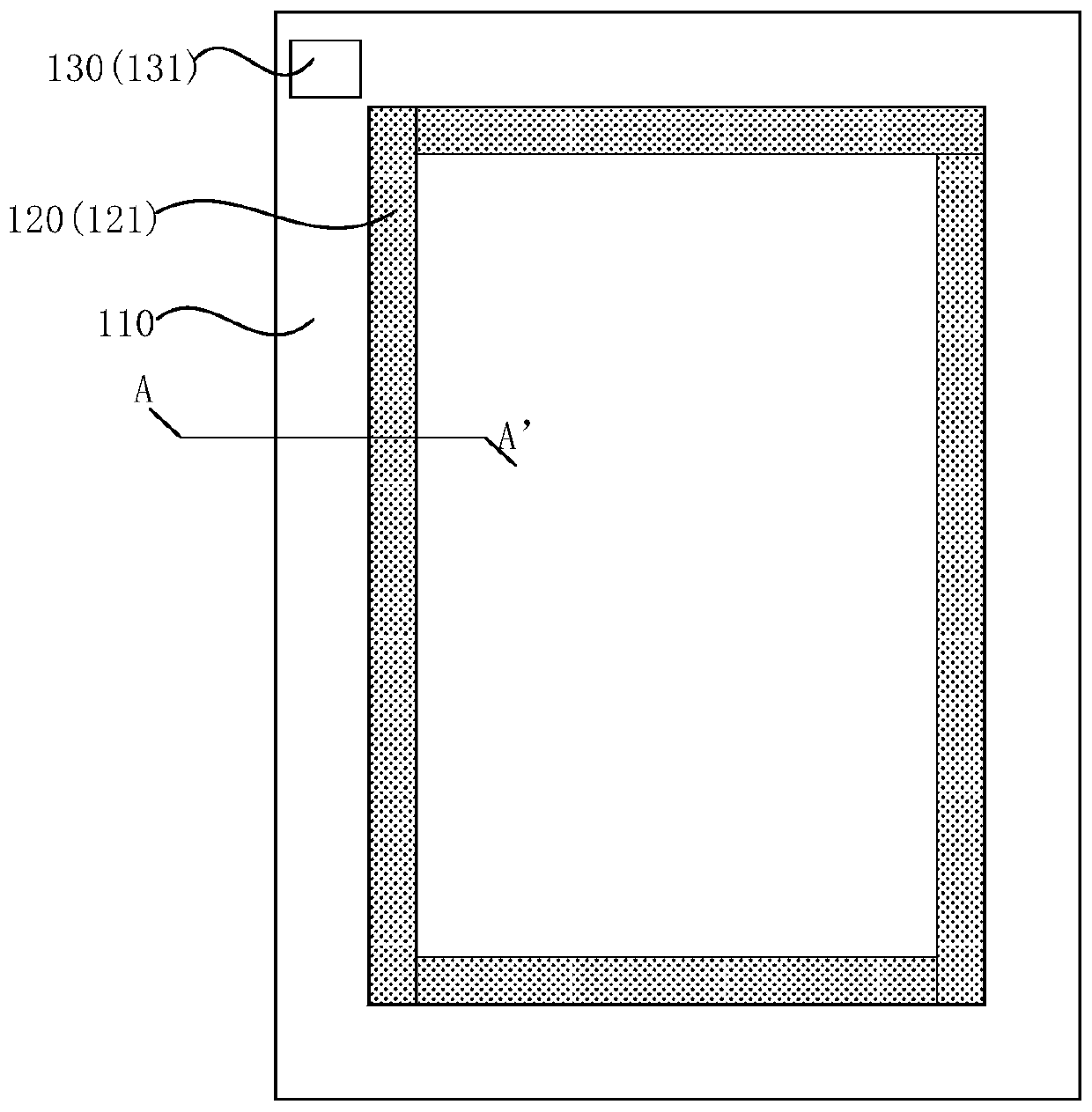

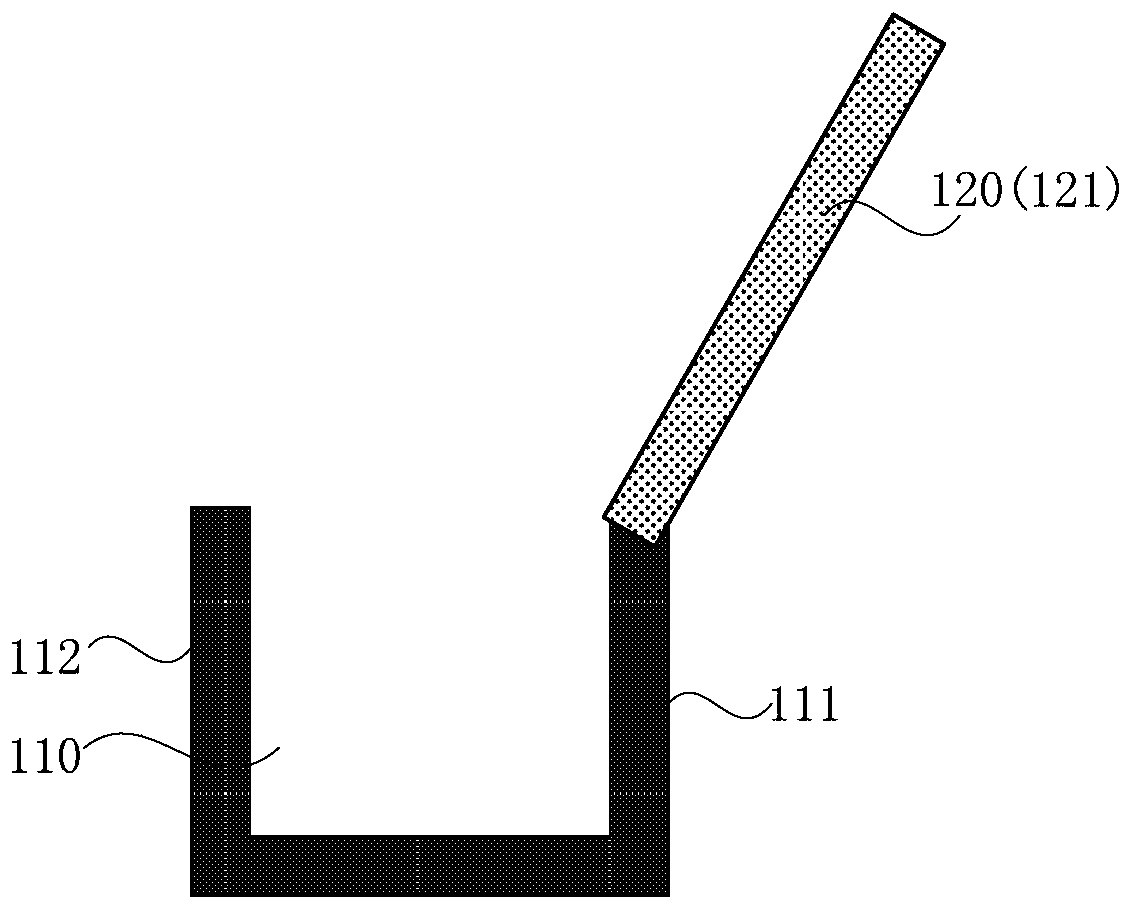

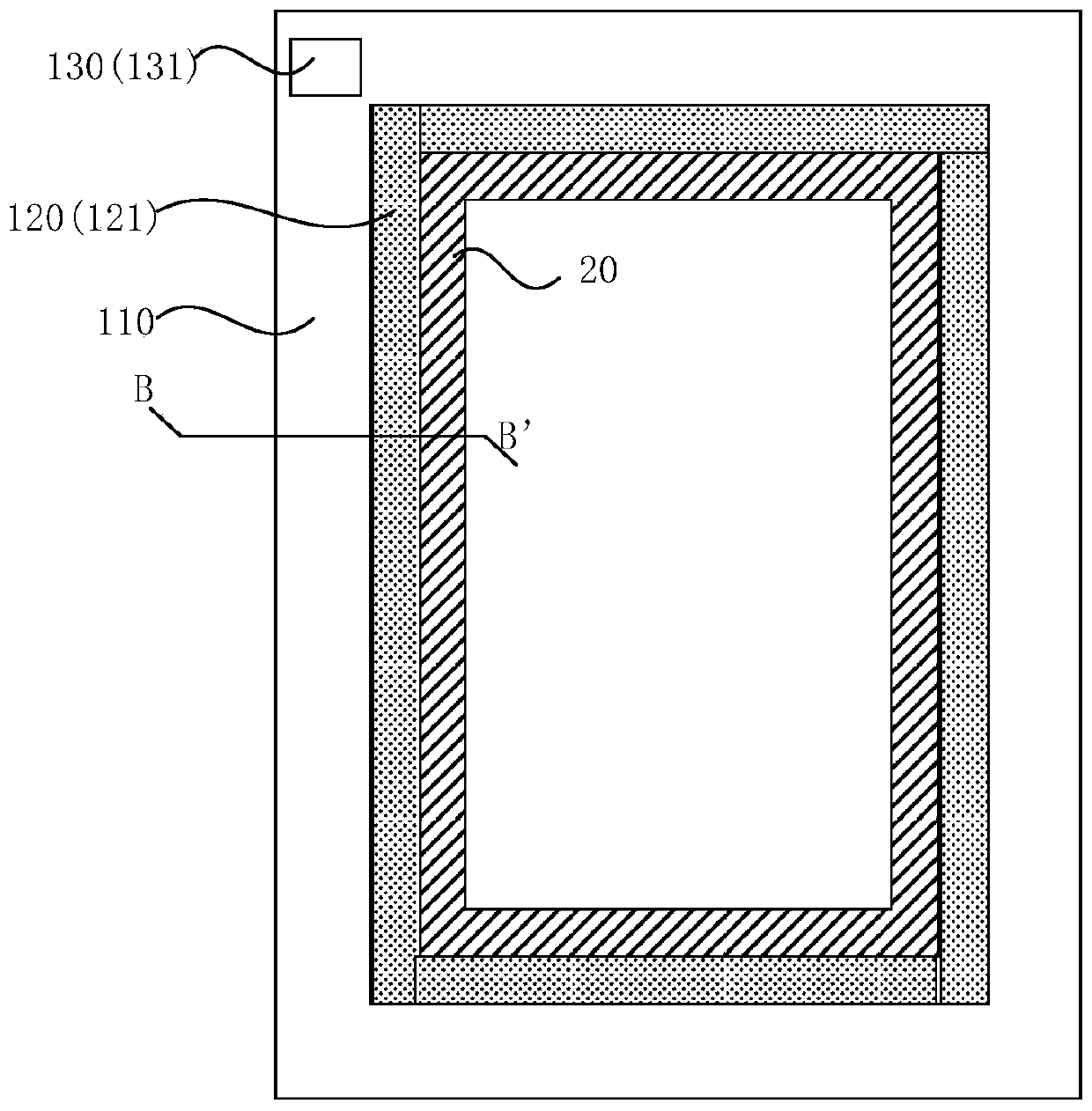

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, rather than to limit the present invention. In addition, it should be noted that, for the convenience of description, only some parts related to the present invention are shown in the drawings but not all structures.

[0030] At present, there are many cutting processes in the manufacture of metal masks. For example, in the process of making a metal mask, it is generally necessary to stretch the mask strip, the support strip and the mask strip to the metal mask frame, wherein the mask strip is arranged on the shield strip and the support strip Above, a mask pattern is formed on the mask strip, and the shielding strip is located between two adjacent mask strips, used to cover the gap between two adjacent mask strips, and the lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com