Prefabricated prestressed composite box girder

A technology of prestressed and combined boxes, applied in bridges, bridge parts, bridge materials, etc., can solve problems such as poor fatigue resistance, low durability of external prestressed beams, and difficult transportation, so as to improve construction speed and quality, and reduce beams The effect of body weight and avoiding shrinkage deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

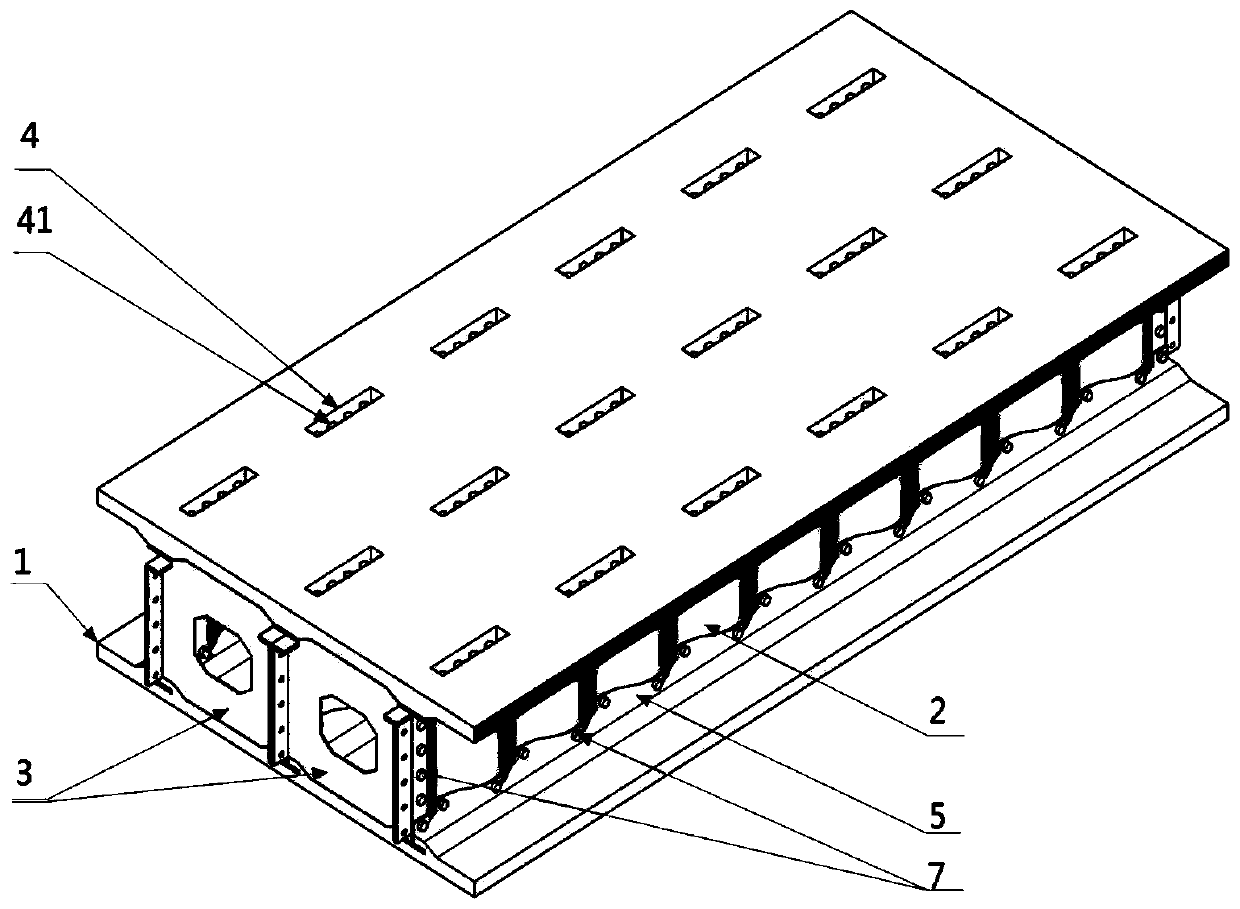

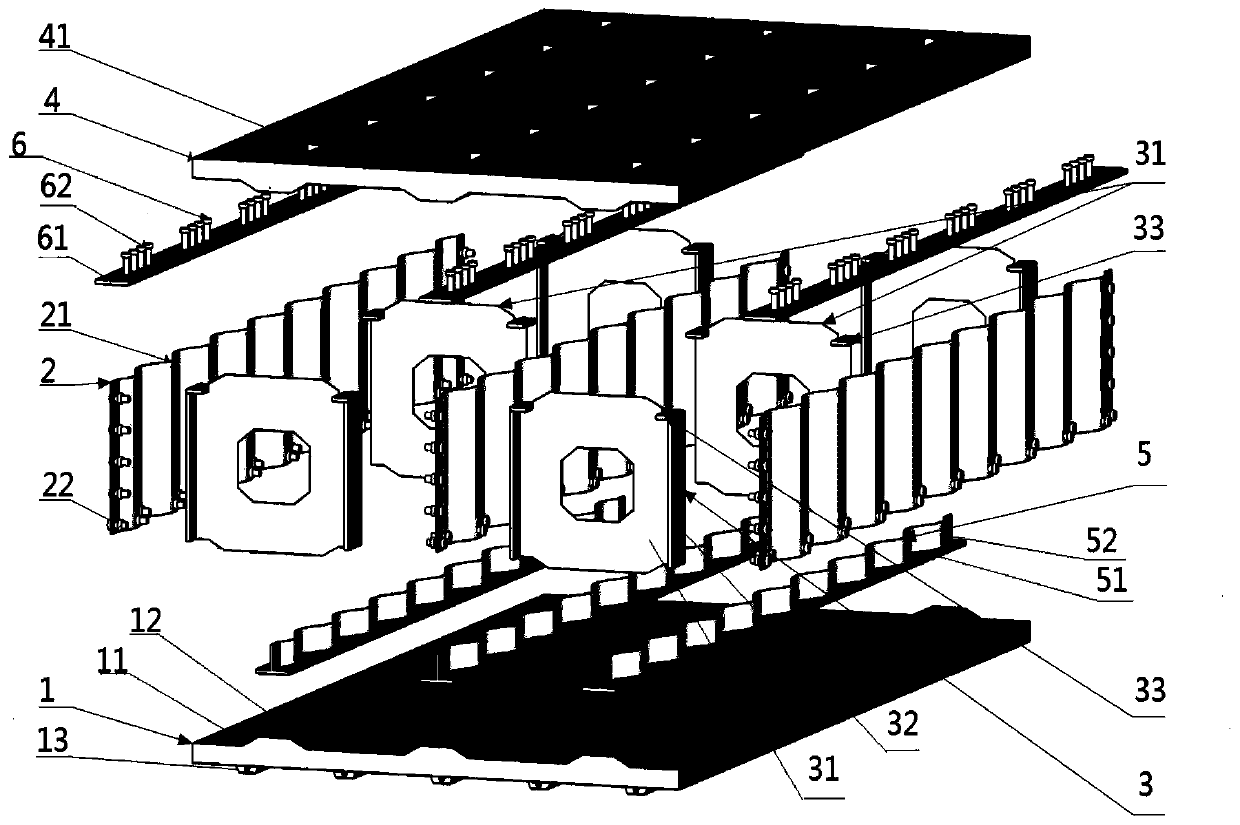

[0027] Preferred embodiment one, such as figure 1 , figure 2 As shown, this prefabricated prestressed composite box girder disclosed in this embodiment is suitable for the case where the span of the beam is relatively short. and top plate4.

[0028] Such as figure 1 , figure 2 As shown, the base plate 1 is a prefabricated concrete integral plate, including a plate main body 11 , an upper boss 12 and a lower boss 13 . Wherein the plate main body is a rectangular plate, the sections of the upper boss and the lower boss are trapezoidal, the lower bottom surface of the upper boss is located on the upper surface of the plate main body, and the lower bottom surface of the lower boss is located on the lower surface of the plate main body. In the lower boss, there are tunnels for steel tendons to pass through along the length direction. There is a reserved space between the boss and the end of the bottom plate, so that the prestressed tendons can be stretched and anchored to me...

Embodiment 2

[0032] Preferred embodiment 2. The difference between this embodiment and preferred embodiment 1 is that this embodiment is suitable for the case where the beam span is long, and it includes multi-section box girder units, and each section of box girder units passes through the connecting plate on the end plate After the splicing is completed, the strip plates in the two adjacent box girder units are all extended to the same connecting plate and then welded to complete the splicing of the steel structure, and then concrete is poured into the back pouring hole to ensure the integrity, and the adjacent two box girder units The joints between the beam units are filled with epoxy resin to ensure reliable connection.

[0033] In addition, the present invention can also set multi-box type or single box type according to different widths of beams.

[0034] To sum up, the present invention selects different combinations according to different beam widths and beam spans during specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com