Antifreeze system for air inlet wellbore of underground mine in high-cold region

A technology of anti-freeze system in alpine regions, applied in general control system, control/regulation system, ventilation of mine/tunnel, etc., can solve problems such as limited installation space, affecting occupational health and safety, high energy consumption for preheating and anti-freezing , to achieve the effect of overcoming the limited installation location, economical and reasonable frozen well problems, and solving the frozen well problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

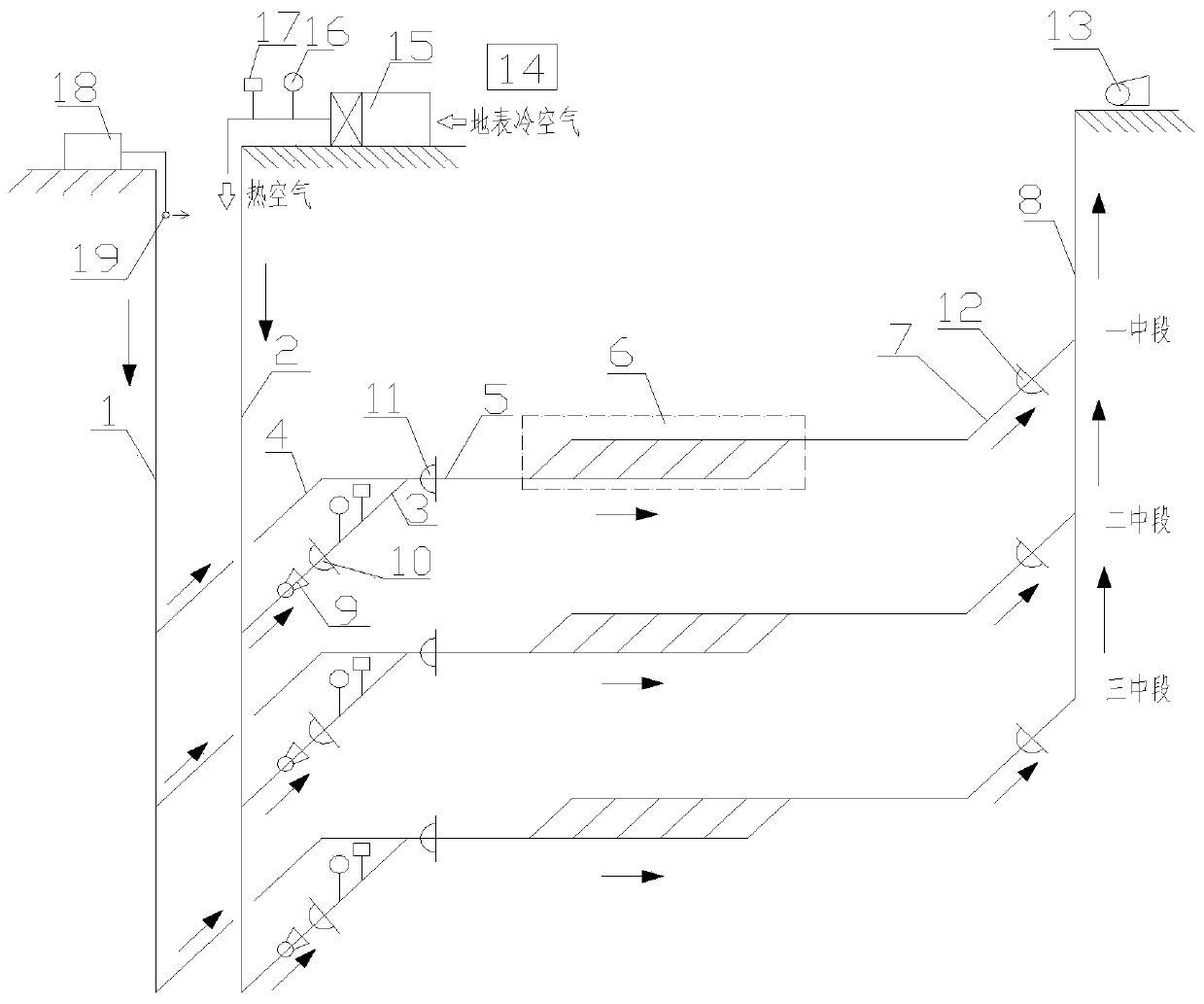

[0023] In order to better describe the present invention, a kind of antifreeze system of the present invention for the air intake shaft of underground mines in alpine regions will be further described in detail below in conjunction with the accompanying drawings.

[0024] Depend on figure 1The schematic diagram of the structural layout of a kind of antifreeze system used for the air intake shaft of an underground mine in the alpine region shown in the present invention shows that the auxiliary shaft 1, the air intake shaft 2, and the return air shaft 8 are arranged vertically, and the middle section of the air inlet lane 5 is arranged horizontally , the auxiliary well stone door 4 and the air inlet lane 3 are arranged obliquely, the auxiliary shaft 1 and the middle air inlet lane 5 are connected through the auxiliary shaft stone gate 4, and the air inlet shaft 2 and the middle air inlet lane 5 are connected through the air inlet shaft The joint roadway 3 is connected, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com