Sound transmission curtain and manufacturing method thereof

A manufacturing method and sound-transmitting technology, applied in optics, instruments, projection devices, etc., can solve problems affecting sound effects, small hole moiré fringes, sound wave diffraction, etc., and achieve the effect of eliminating moiré fringes and diffraction phenomena and improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

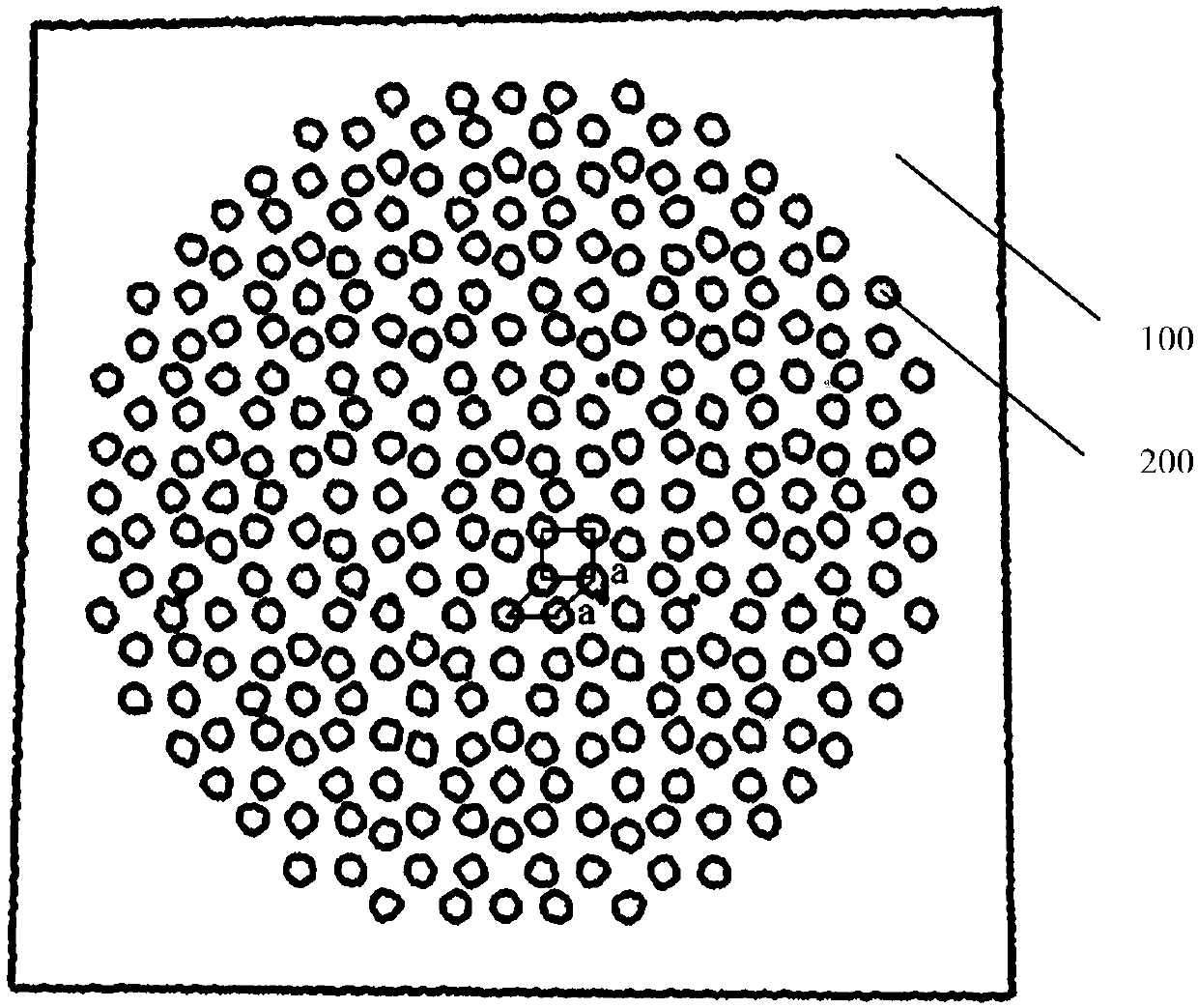

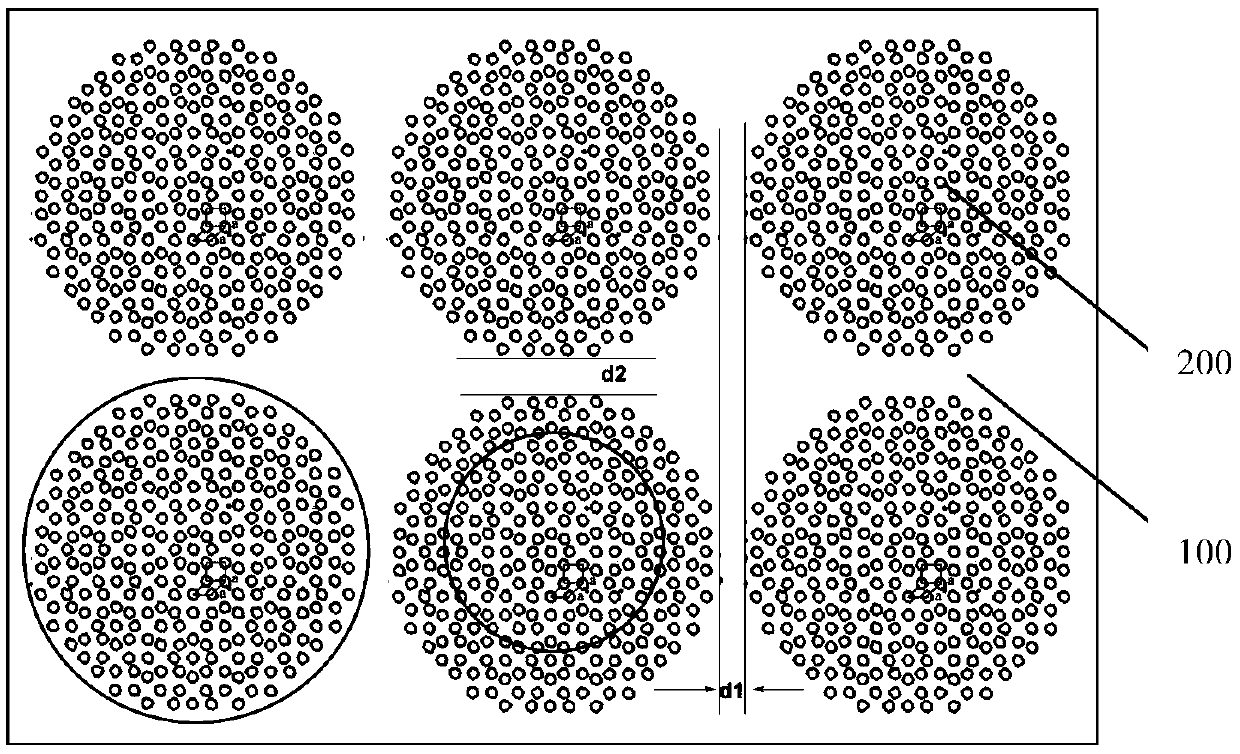

[0020] figure 1 Schematic diagram of the structure of the sound-permeable curtain of the present invention Figure 1 ; figure 2 Schematic diagram of the structure of the sound-permeable curtain of the present invention Figure II . like figure 1 and figure 2 As shown, the present invention provides a sound-transmitting curtain, which includes a sound-transmitting curtain substrate 100 and a sound-transmitting hole 200 disposed on the sound-transmitting curtain substrate 100, and the sound-transmitting hole 200 is at least partially The sound curtain substrate 100 is arranged in a two-dimensional quasicrystal array. The material of the sound-transmitting curtain substrate 100 is polyvinyl chloride (PVC), polycarbonate (PC) or polyethylene terephthalate (PET), and the sound-transmitting hole 200 is arranged on the sound-transmitting curtain Through holes on the substrate 100, the sound emitted from one side of the sound-transmitting curtain can reach the other side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com