A kind of online detection method and system of micro wear amount of superhard material grinding wheel

A superhard material and detection method technology, which is applied in the direction of grinding machine parts, grinding/polishing equipment, workpiece feed movement control, etc., can solve the problem of micro wear detection of grinding wheels without superhard materials, and achieve detection Fast and efficient, guaranteed detection accuracy, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

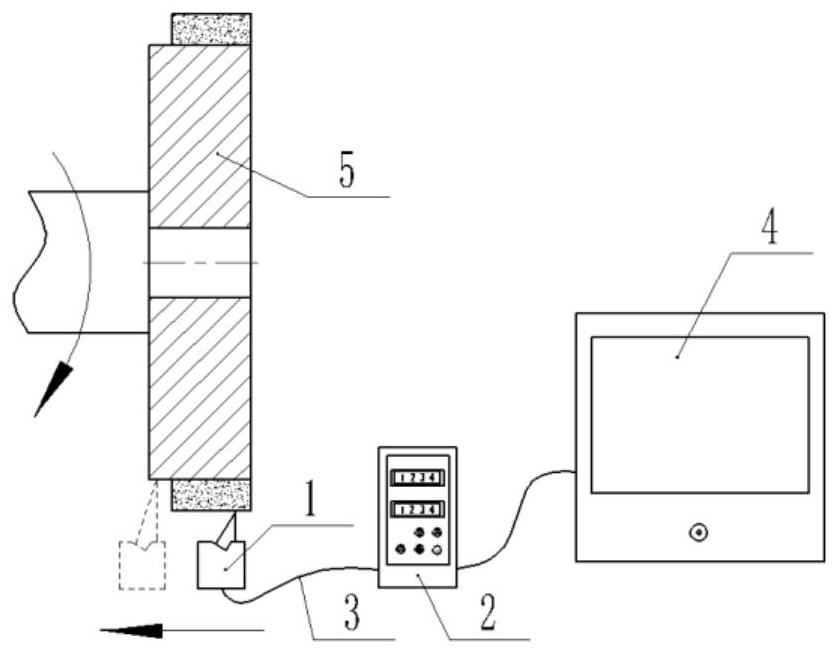

[0045] Example of an online detection system for the micro wear of superhard material grinding wheels:

[0046] The on-line detection system of the micro-abrasion amount of the superhard material grinding wheel proposed in this embodiment is as follows: figure 1 As shown, it includes a grinding wheel 5, a laser displacement sensor 1, a controller 2 and a computer 4. The laser displacement sensor 1 is arranged in front of the outer surface of the grinding wheel 5, so that the irradiation direction of the laser spot (that is, the emitted light beam) emitted by the laser displacement sensor 1 is vertical. The outer surface of the grinding wheel 5 passes through the center of the axis of the grinding wheel 5 , the laser displacement sensor 1 is connected to one end of the controller 2 through the data cable 3 , and the other end of the controller 2 is connected to the computer 4 .

[0047] In this embodiment, in order to facilitate the installation of the laser displacement sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com