Method for reducing organic matter on silicon block surface and method for preparing single crystal silicon

A technology of organic matter and silicon block, which is applied in the direction of surface etching composition, single crystal growth, single crystal growth, etc., can solve problems such as unclear carbon pollution, and achieve the effect of reducing the concentration of organic matter and avoiding wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0101] The embodiment of the present invention discloses a method for preparing monocrystalline silicon, which is prepared by the Czochralski method by using the silicon block described in the above technical solution as a raw material.

[0102] The invention also discloses a single crystal silicon, which is produced by the method described in the above technical solution, and the concentration of carbon-containing impurities is below 50ppba.

Embodiment 1

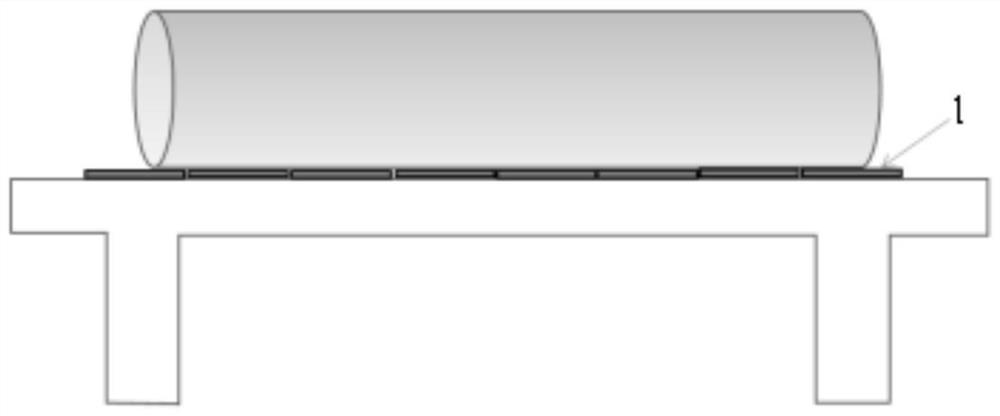

[0105] Breaking the silicon ingot into silicon blocks on a Teflon plate, and then using the Teflon plate to transport the silicon blocks above the etching container;

[0106] Two pillars are arranged between the two opposite side walls of the etching container, and the two pillars divide the etching container into a first area, a second area and a third area; the first area, the second The volume of the area and the third area are equal.

[0107] Four side panels surrounded by a square are arranged in the first area;

[0108] Four side panels surrounded by a square are arranged in the second area;

[0109] Four side panels forming a square are arranged in the third area;

[0110] There is a gap between the side wall and the side panel of the etching container.

[0111] Cooperating with the etching container, the length of one side of the Teflon plate is equal to the distance between the two pillars.

[0112] Tilt the Teflon plate to slide the silicon block into the etching...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com