Shell structure and assembly method of multi-parameter water quality detection equipment

A water quality detection, multi-parameter technology, applied in measuring devices, measuring heat, measuring fluid pressure, etc., can solve the problems of high use and maintenance costs, complex assembly process, single overall structure, etc., to achieve low production and maintenance costs, and the installation process. Flexible, easy-to-process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

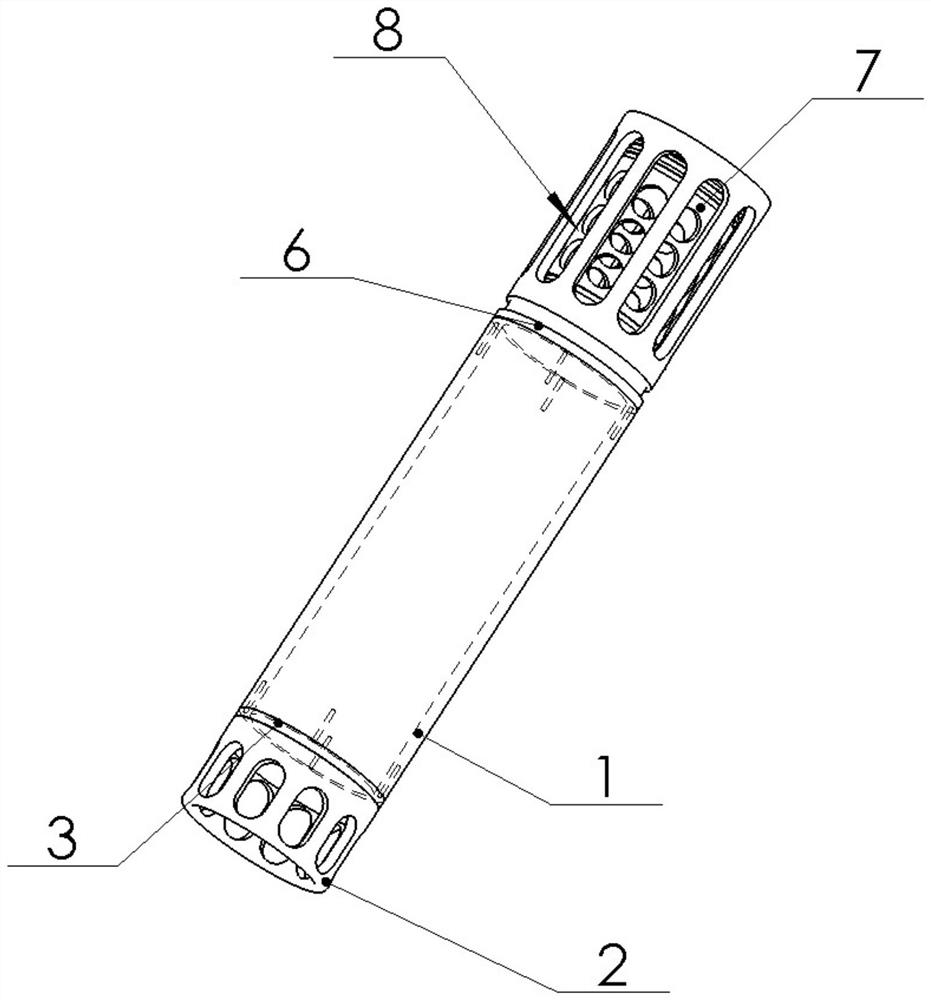

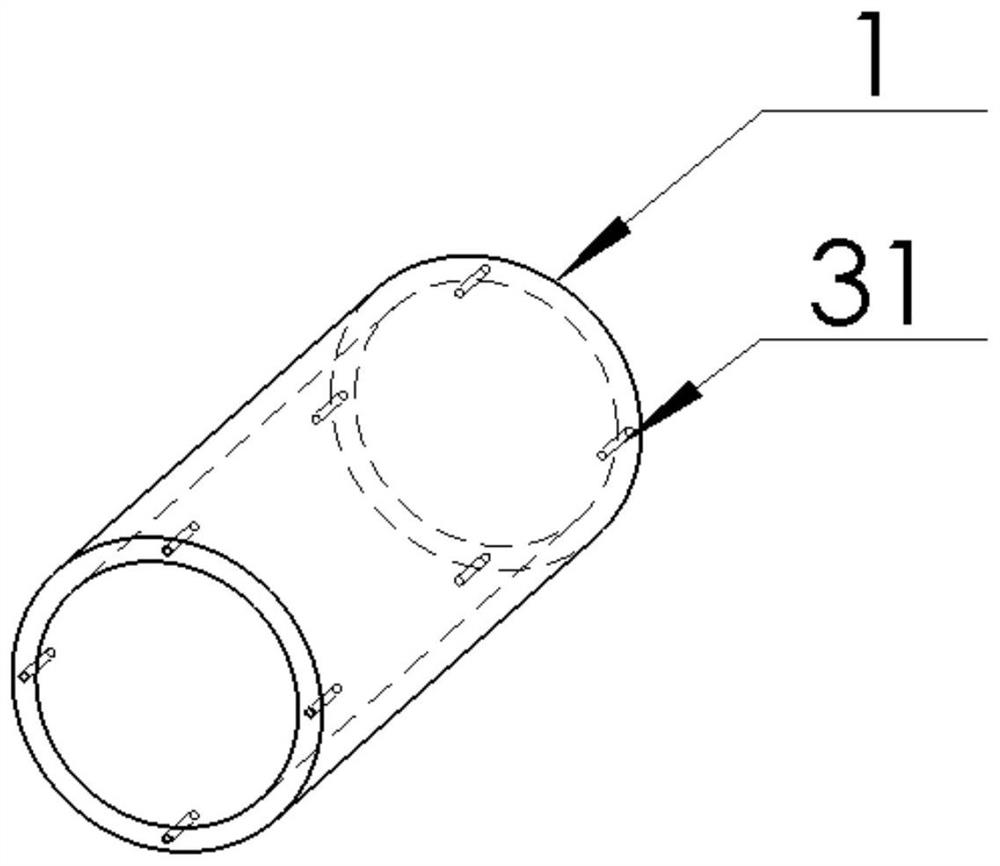

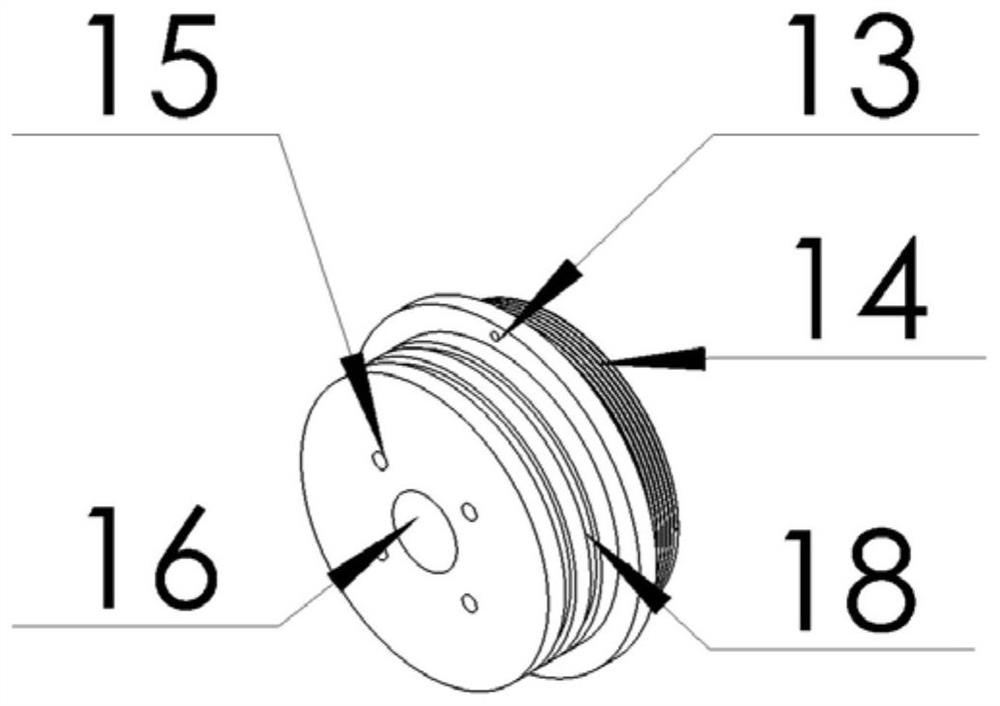

[0039] Example 1, such as figure 1 As shown, this embodiment discloses a shell structure of multi-parameter water quality detection equipment, such as figure 2 As shown, it includes a hollow cylindrical shell 1 provided with screw interfaces 31 at both ends, such as image 3 As shown, a screw interface 13 and a threaded interface 16 for connecting watertight parts are provided on the upper end cover 3 of the housing. The screw interface of the housing and the screw interface of the upper end cover are connected by screws. In addition, the upper end cover is located The part inside the housing is provided with a copper post buried hole 15 and a sealing groove 18 for placing a sealing O-ring, and the circuit fixing plate 17 in the case is fixed on the upper end cover through the copper post inserted into the copper post buried hole, and the upper end cover is located outside the case The part set threaded interface 14, such as Figure 5 As shown, the protective cover 2 with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com