Material supplier production capacity monitoring and abnormity early warning method based on electricity consumption analysis

A technology of production capacity and power consumption, which is applied in the field of material supplier production capacity monitoring and abnormal early warning based on power consumption analysis, can solve the problem of large manpower and material resources demand for supplier production risk prevention work, and the safety and stability of the power grid system. Hidden dangers, insufficient capacity of suppliers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Embodiment 1 Monthly early warning of production status of material suppliers

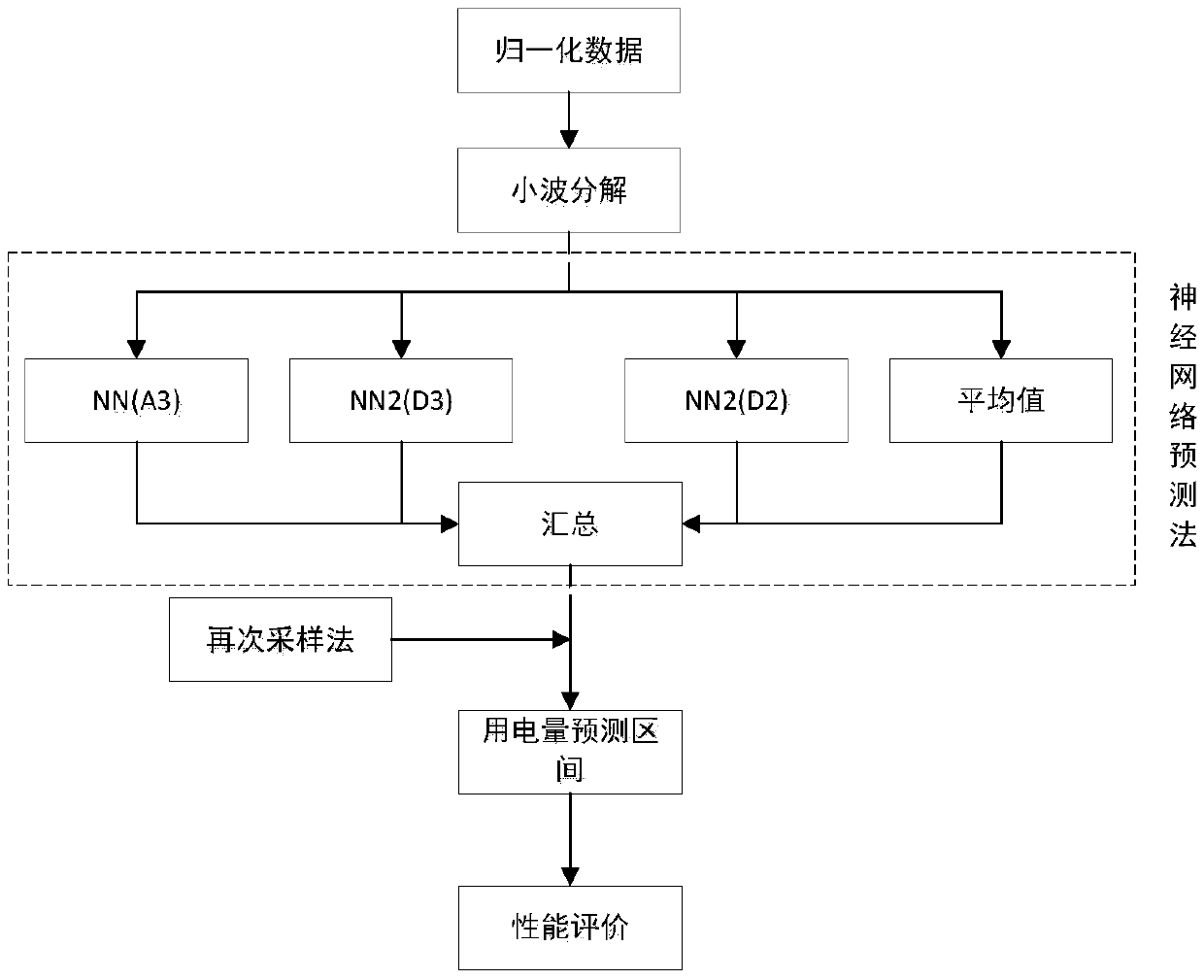

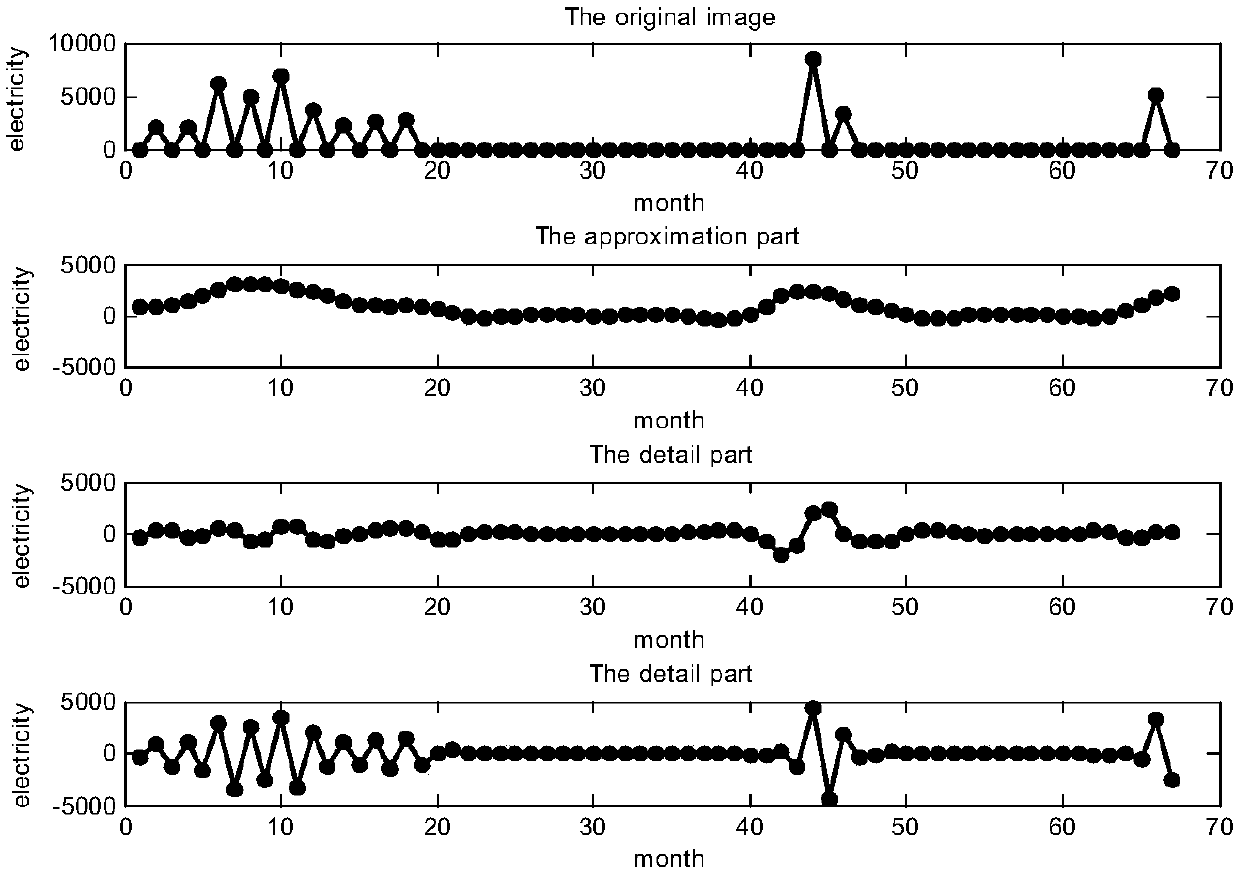

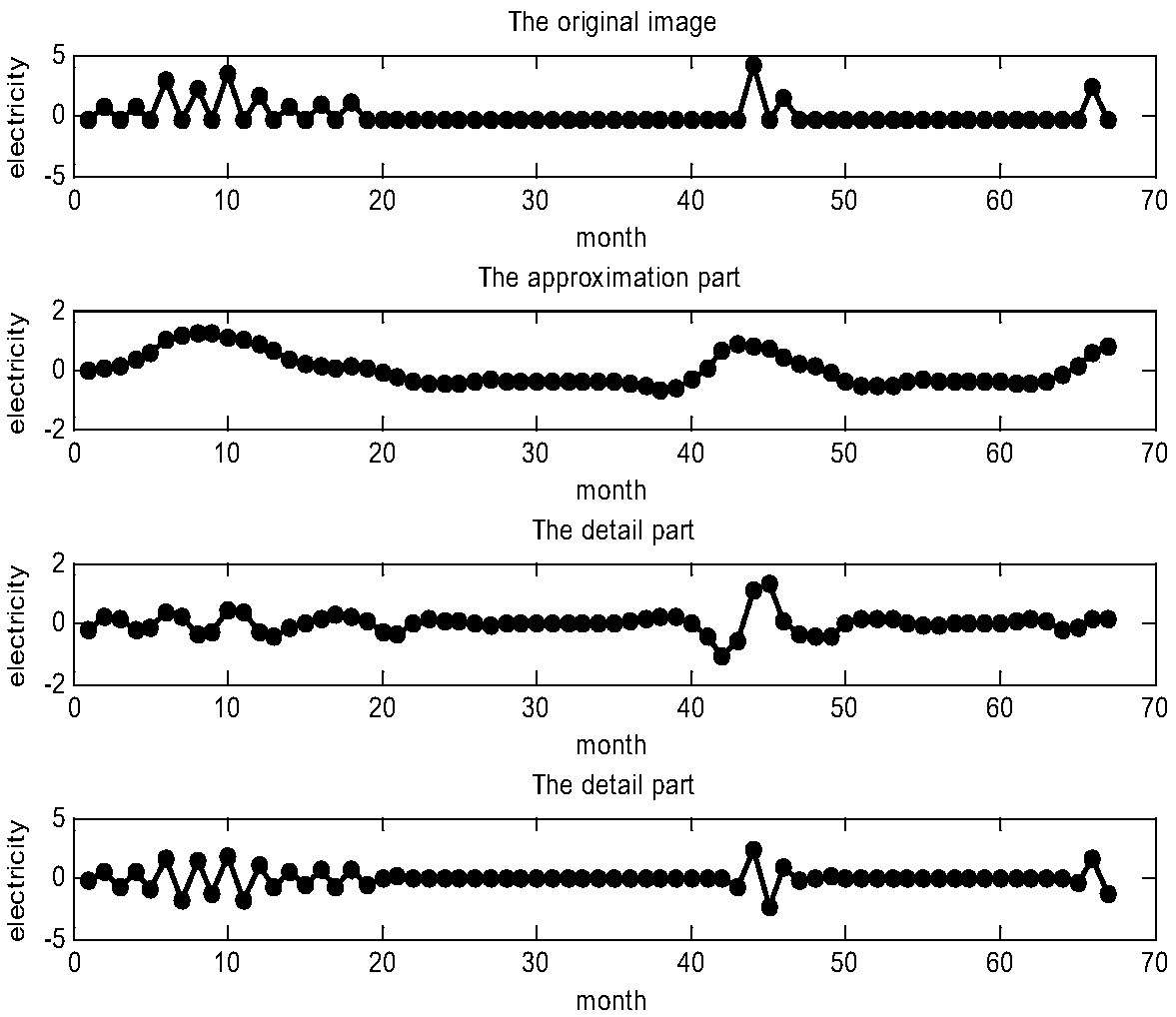

[0073] A kind of monthly early warning in the material supplier production monitoring and early warning model method based on electricity consumption analysis, comprises the following steps (such as figure 1 ), first use the normalization method to standardize the data, and use the wavelet decomposition to separate the power consumption data into trends and fluctuations, so as to dig out the abnormal power consumption data; predict the supplier's power consumption data in the next month by using the neural network algorithm , use the re-sampling method to predict a reasonable fluctuation range, and set a warning range for electricity consumption in the next month.

[0074] Set up the early warning model target, dig out the possible abnormal power consumption data in the historical data, and the month when the abnormal power consumption occurs, predict the power consumption data of the next m...

Embodiment 2

[0130] Example 2 Annual early warning example and optimization of material supplier production monitoring and early warning

[0131] When conducting annual early warning research, collect the electricity consumption and main business data of a certain type of material supplier from 2011 to 2013, and obtain the electricity consumption value per unit income of the supplier from 2011 to 2013, through statistical analysis (such as Figure 8 ), the distribution of the series is relatively average, showing a gradual enlargement trend, which is in line with the normal distribution in statistics, the deviation of the series distribution is not large, and there are occasional maximum values (such as Figure 9 ). Based on this, the average value is selected as the reference value of electricity consumption per unit income of the year. At the same time, through the statistical analysis of the electricity consumption data per unit income in the past year and the observation of the data ...

Embodiment 3

[0142] Embodiment 3 Quarterly early warning of material supplier production monitoring and early warning

[0143] The quarterly power consumption warning for suppliers is based on the analysis of the annual power consumption per unit revenue standard, and the supplier’s quarterly power consumption per unit revenue is used as a reference indicator.

[0144] Quarterly electricity consumption per unit income is calculated as follows:

[0145] Quarterly electricity consumption per unit income (kWh / 10,000 yuan) = sum of electricity consumption in the past three months (kWh) / (1 / 4×annual main business income) (10,000 yuan)

[0146] Take the average as the reference value of electricity consumption per unit income in the quarter. At the same time, through statistical analysis of historical quarterly electricity consumption data per unit income and observation of the data relationship between the minimum, average, and maximum values, the same industry, suppliers The lowest value of qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com