Timing oiling device for reciprocating type crankcase

A refueling device and crankcase technology, which is applied in variable capacity pump components, liquid variable capacity machines, machines/engines, etc., can solve the problem of affecting the operation efficiency and performance of equipment, not conforming to modernization, automation, and equipment gas storage effect. To solve the problem of good and other problems, to achieve the effect of accurate and timely lubricating oil supply, simple and ingenious structure, and better lubricating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific drawings and embodiments.

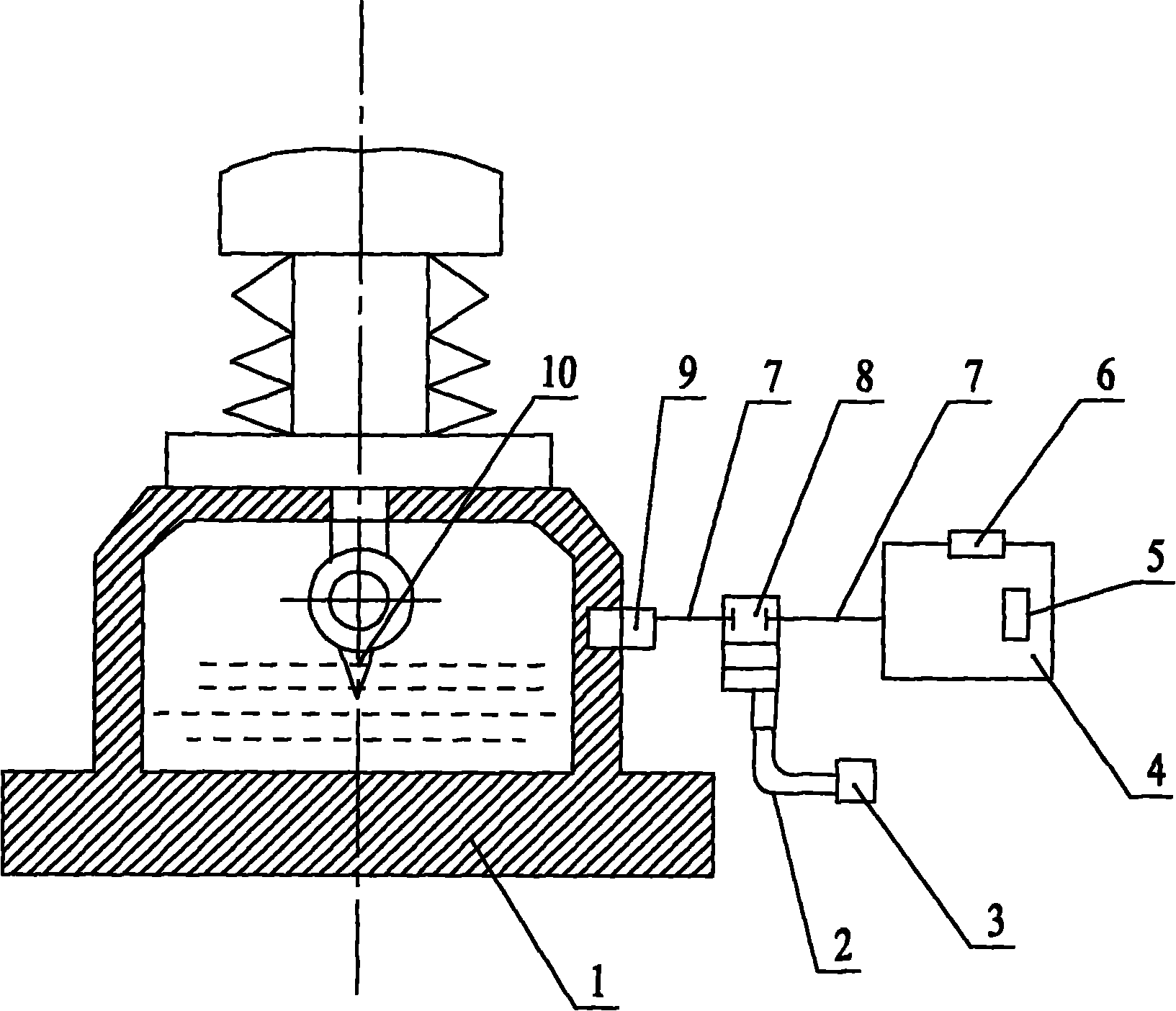

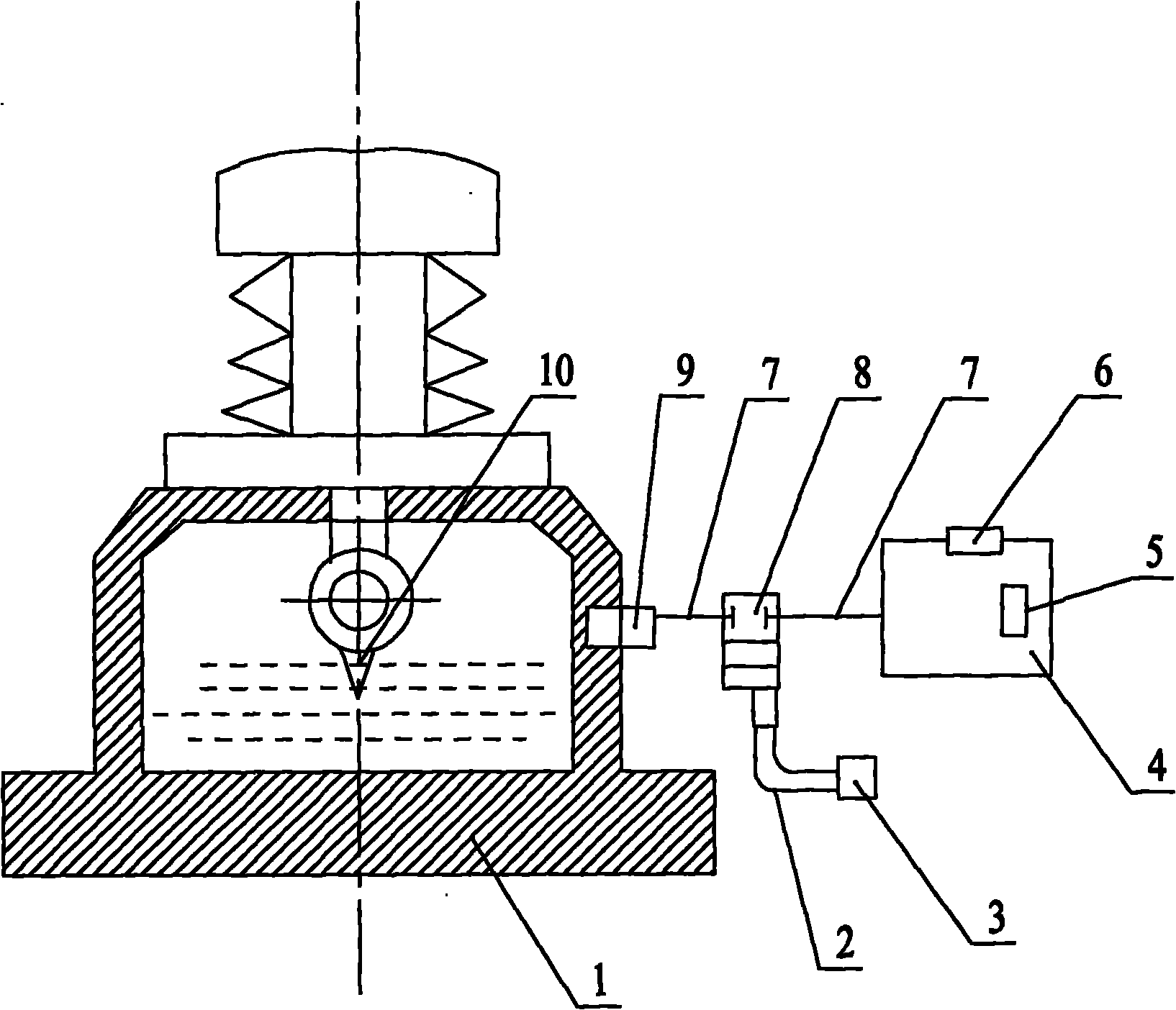

[0011] Such as figure 1 As shown, the present invention is mainly made up of crankcase 1, joint 9, solenoid valve 8, auxiliary fuel tank 4, electric controller 3 and oiling needle 10; Joint 9 is arranged on the box body of crankcase 1, and joint 9 connects electromagnetic The valve 8 is connected, and the solenoid valve 8 is connected with the auxiliary oil tank 4 through the pipeline 7; The auxiliary fuel tank 4 is provided with an oil sight glass 5 and a fuel tank cover 6; the oil sight glass 5 is used to observe the oil quantity in the auxiliary oil tank 4, so as to replenish in time when lacking oil. An oiling needle 10 is installed in the crankcase 1, and the oiling needle 10 is driven to rotate by a transmission device.

[0012] Work process and working principle of the present invention are as follows:

[0013] The power mechanism drives the oiling ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com