Material conveying mechanism for helium balloon vending machine

A vending machine and helium balloon technology, which is applied in the field of toy vending machines, can solve the problems of difficulty in realizing movements, complicated balloon circulation steps, etc., and achieve the effects of compact structure, strong functionality and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

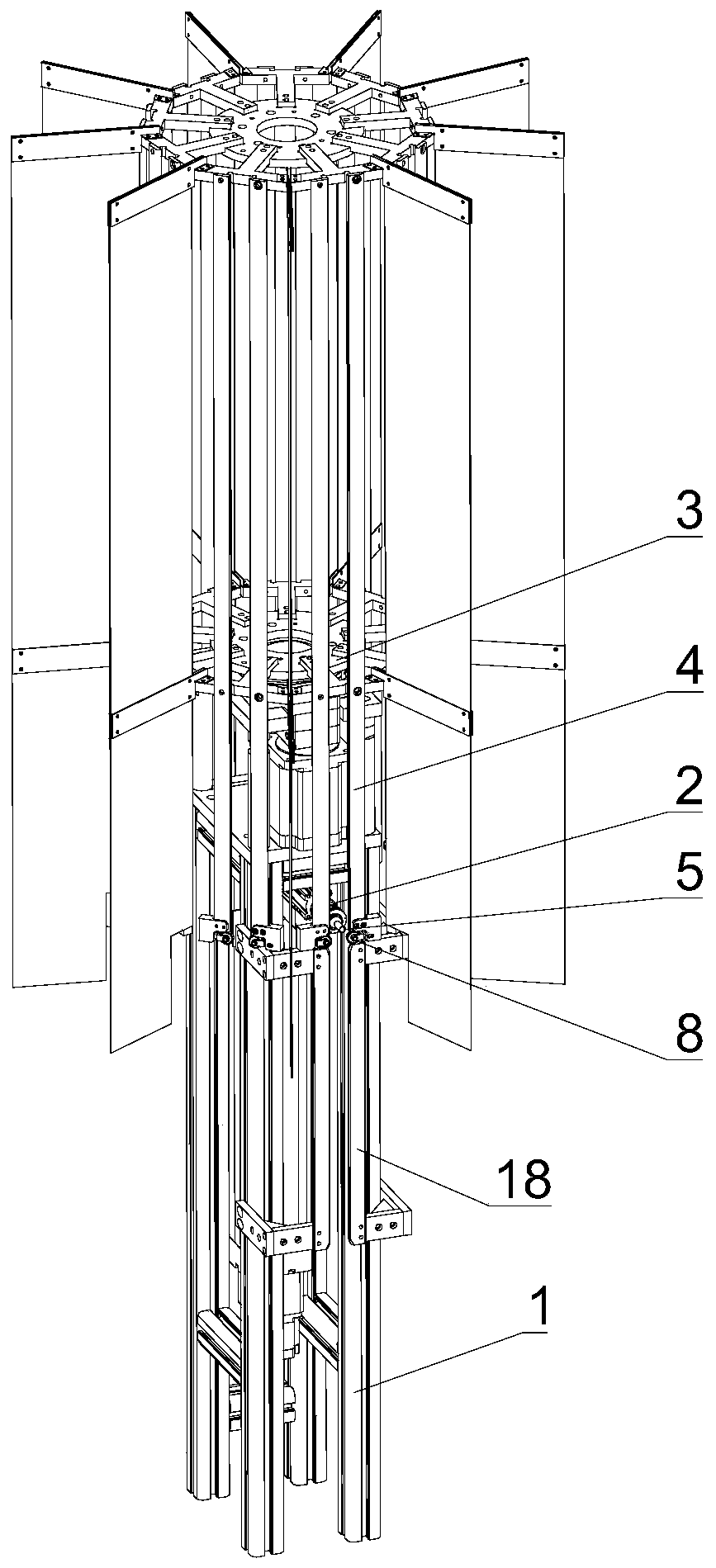

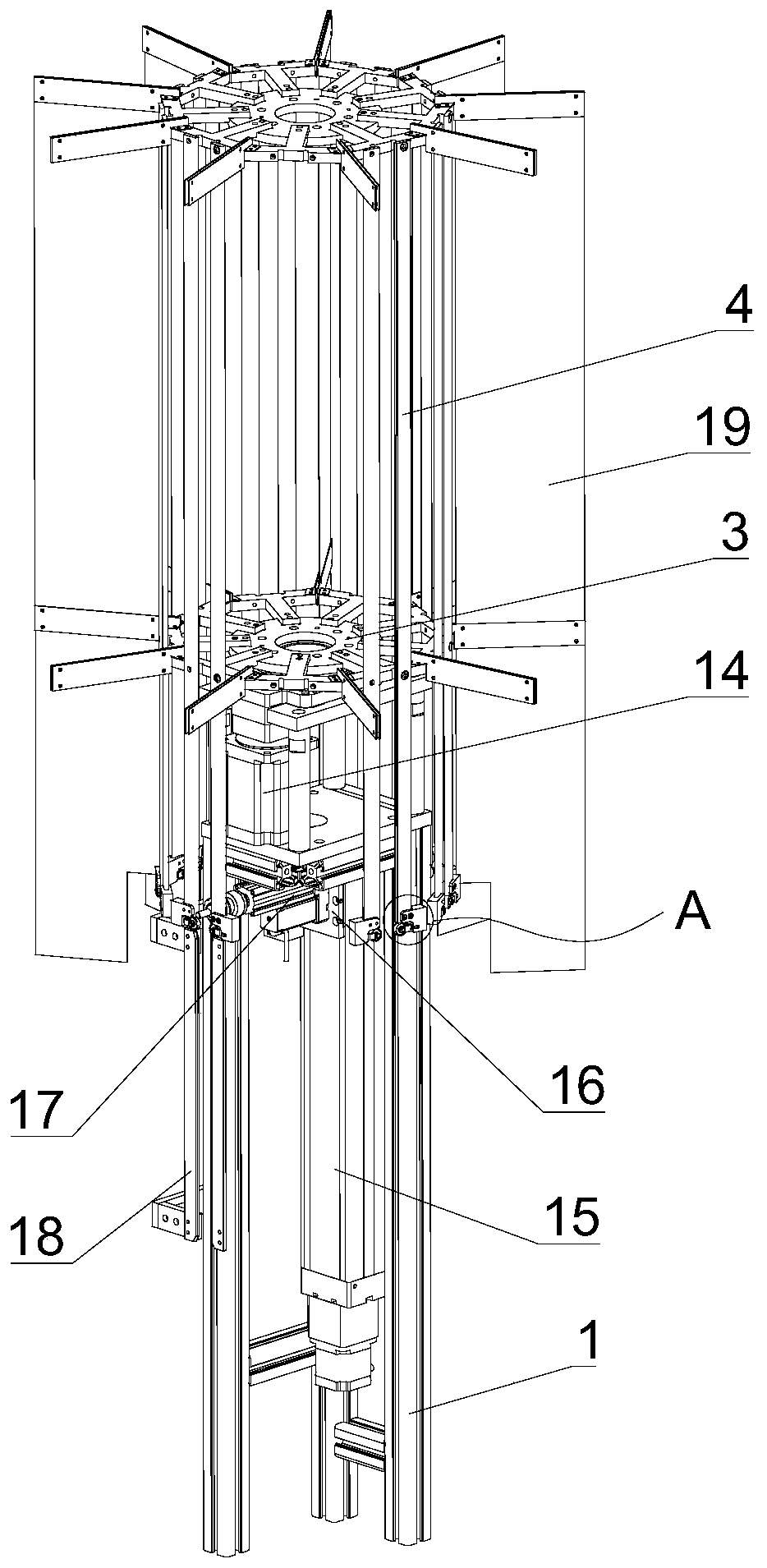

[0024] see Figures 1 to 5 As shown, this embodiment provides a material delivery mechanism for a helium balloon vending machine, which mainly includes a support frame 1 and an inflatable head 2 .

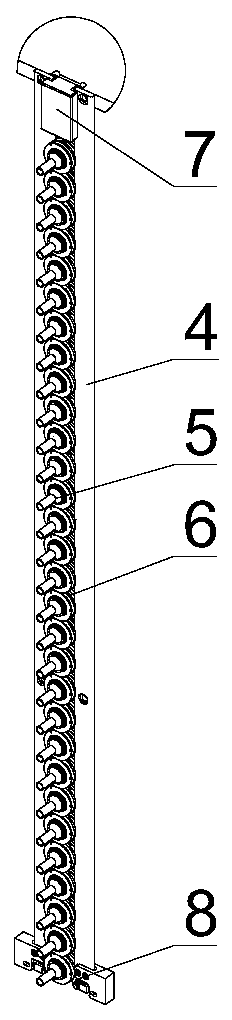

[0025] The supporting frame 1 is hinged with a rotating disc 3, and the rotating disc 3 is provided with a plurality of storage slides 4, the storage slides 4 are preferably erected, and a plurality of balloon nozzles 5 are arranged in the storage slides 4. The balloon gas nozzle 5 at the place is integrated with the balloon body, and the balloon gas nozzle 5 is provided with a guide groove 6, and the guide groove 6 is stuck in the material storage slide 4, so that the balloon valve 5 moves along the material storage slide 4.

[0026] Also be provided with the briquetting block 7 that acts on the top balloon air nozzle 5 in the mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com