Multistage step-up system for X-ray machine

A technology of X-ray machine and booster system, applied in X-ray equipment, electrical components, etc., can solve the problem of low number of primary high-current and high-frequency working turns, and achieve the effects of convenient after-sales maintenance, reduced number of turns, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

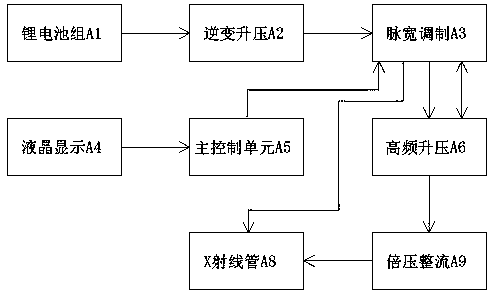

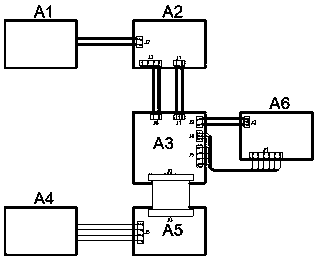

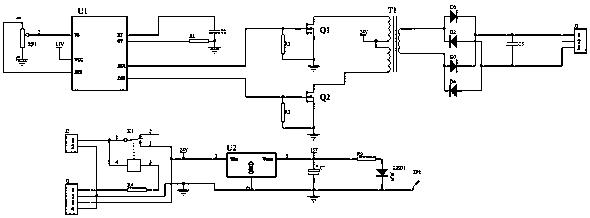

[0031] Such as figure 1 , figure 2 As shown, a multi-stage boosting system for an X-ray machine includes a lithium battery pack A1, a liquid crystal display circuit A4, a main control unit A5, a high-frequency boosting circuit A6, an X-ray tube A8 and a voltage doubler rectifier circuit A9; An inverter boost circuit A2 and a pulse width modulation circuit A3 are also connected in series between the lithium battery pack A1 and the high frequency boost circuit A6; the high frequency boost circuit A6, the voltage doubler rectifier circuit A9 and the X-ray tube A8 are sequentially connected; The liquid crystal display circuit A4 and the pulse width modulation circuit A3 are respectively connected with the main control unit A5; the pulse width modulation circuit A3 is also connected with the X-ray tube A8; the lithium battery pack A1 and the inverter boost circuit A2 are composed A boost circuit; the pulse width modulation circuit A3, the high-frequency boost circuit A6, the volt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com