Non-clamping automatic transplanter

A non-clamping, transplanting machine technology, applied in transplanting machinery, planting methods, excavation/covering trenches, etc., can solve the problems of harsh working environment, reduced work efficiency, low transplanting efficiency, etc., and achieve assembly Simple and fast, guaranteed planting depth, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

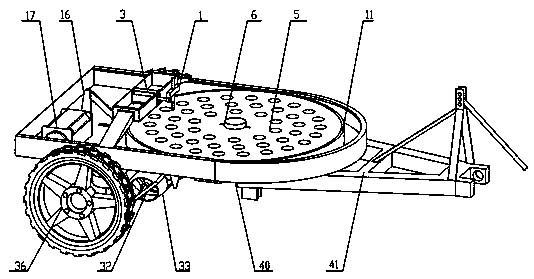

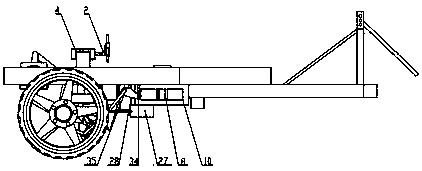

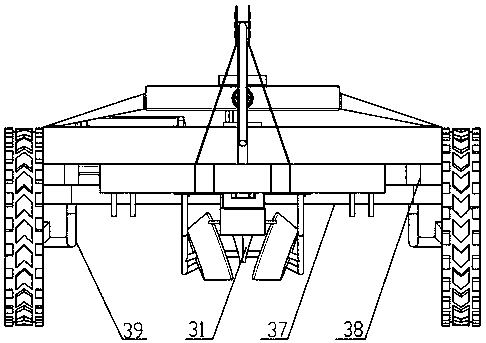

[0025] like Figure 1 to Figure 3As shown, a non-clamping automatic transplanting machine of the present invention includes a seedling pushing device (1), a circular hole seedling tray (5), a seedling tray frame (11), a planting mechanism (42), a frame (40), ground wheel (36), soil-covering wheel (33), suspension traction device (41); the seedling pushing device (1) is connected with the crank slider mechanism 1 (2); the circular seedling tray hole The seedling holes (5-3) are distributed in a circular array at a certain ring distance, and there are grooves (5-2) on both sides of the center hole (5-1); there is a seedling disk rotating device (6 ), the seedling disc rotating device (6) is connected with the stepper motor 2 (8), and the rear end of the seedling disc rack is connected with a crank slider mechanism 2 (16); there is a stepper motor 1 bracket (4) above the frame, The bottom is connected with suspension traction device (41), stepper motor 2 guide rail frame (10), s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com