Fertilizer discharge and conveying device for fertilizer applicator

A technology for conveying devices and fertilizing machines, which is applied in fertilizing devices, fertilizer distributors, agriculture, etc. It can solve the problems of wet and melted fertilizer granule surfaces, wet fertilizer granule surfaces, and poor fluidity, so as to facilitate transportation and prevent failures , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, wherein the schematic embodiments and descriptions are only used to explain the present invention, but are not intended to limit the present invention.

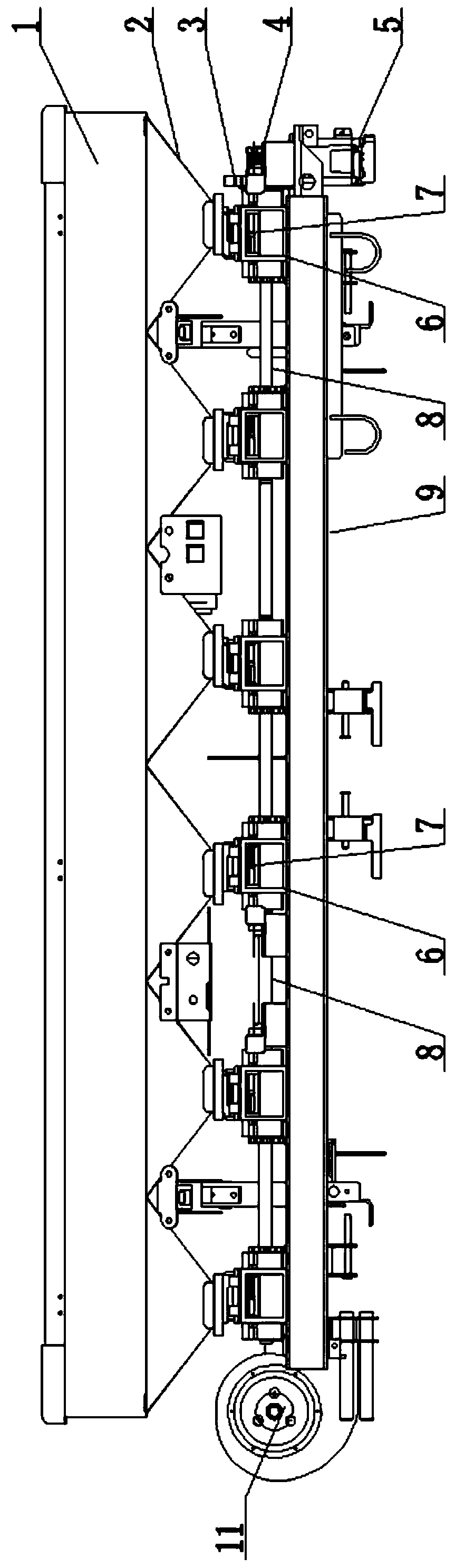

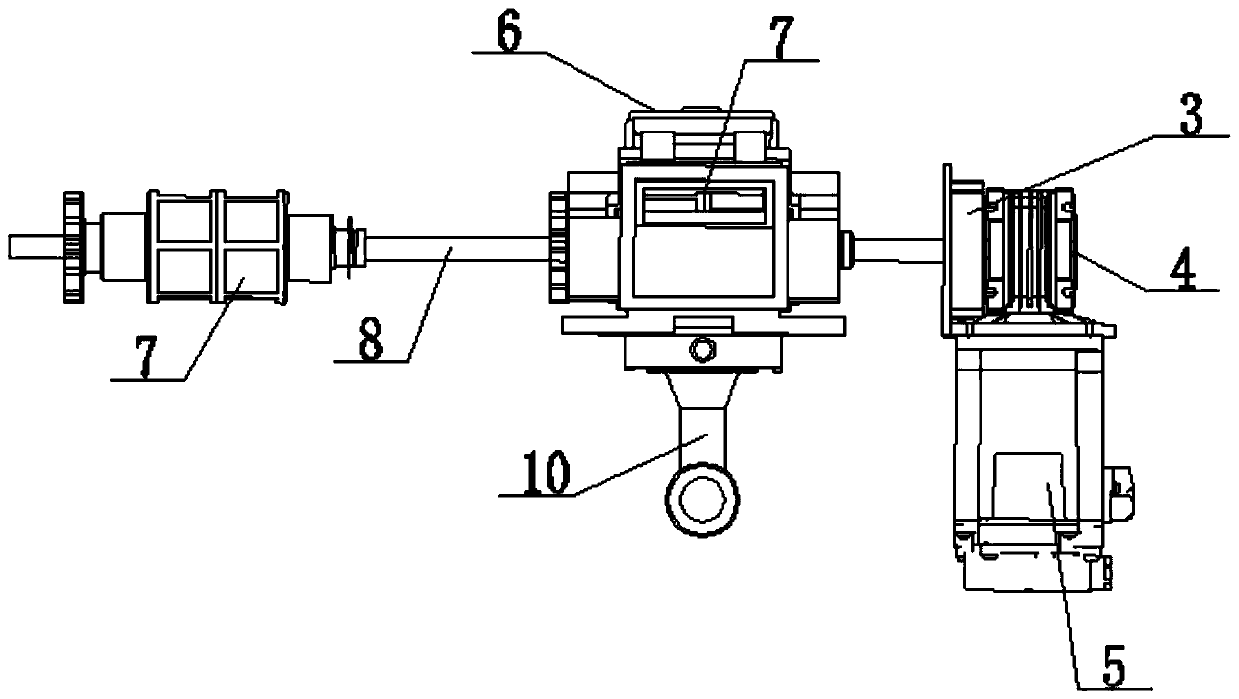

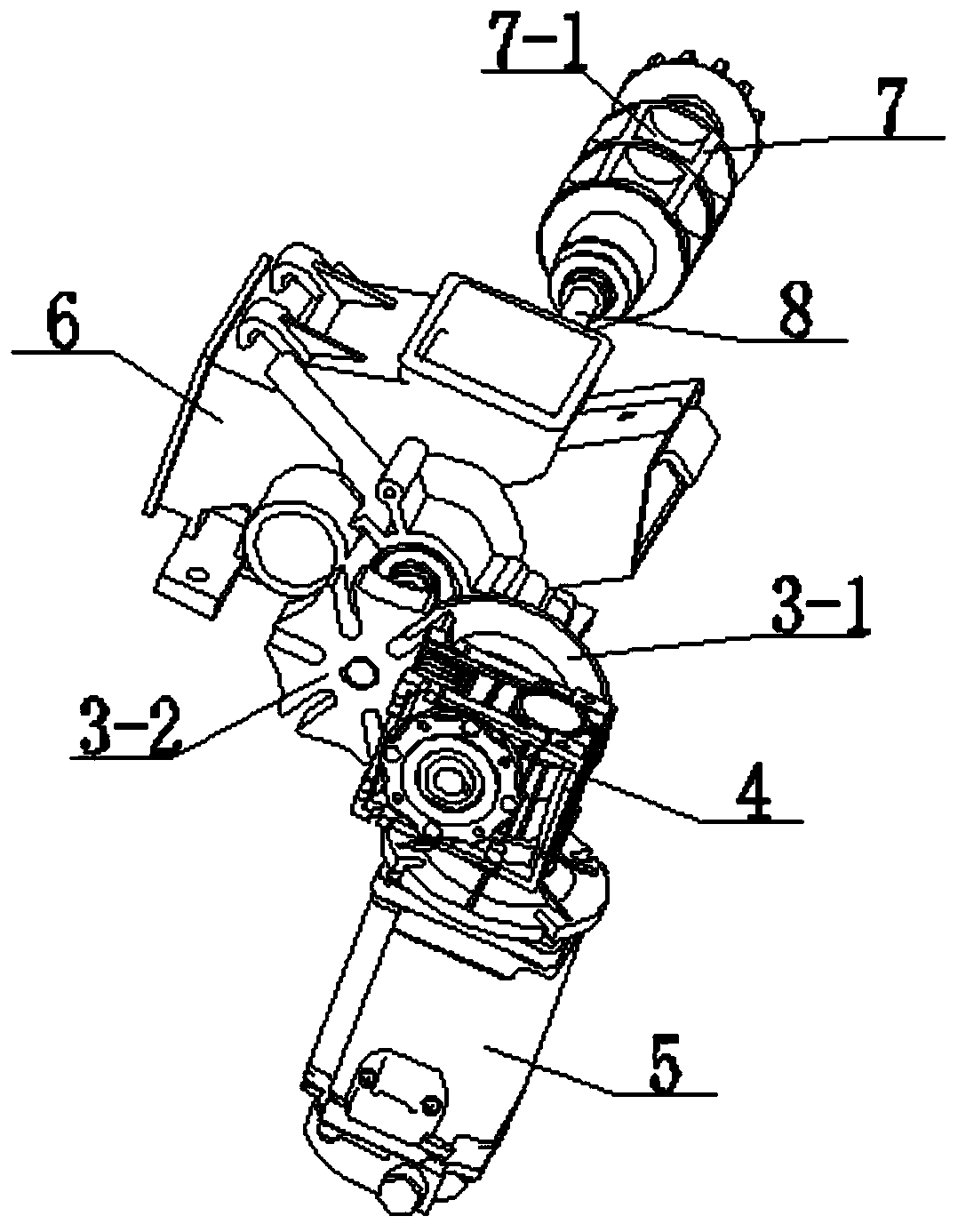

[0023] Such as Figure 1-6 As shown, the fertilizer discharge and conveying device of the fertilizer spreader described in this specific embodiment includes a fertilizer box 1, a sheave mechanism 3, a gear box 4, a drive motor 5, a plurality of fertilizer discharge boxes 6, and a fertilizer discharge box 6 The fertilizer discharge wheel 7, the fertilizer discharge shaft 8, the steel frame 9, and the fertilizer delivery pipe connection socket 10 corresponding to the quantity; the fertilizer tank feed port 2 at the bottom of the fertilizer tank 1 and the upper port of the fertilizer discharge box 6 are docked for detachable installation Fixed; multiple fertilizer discharge wheels 7 are set on a ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap