A screening and feeding mechanism for irregular mim shaped products

An irregular and product technology, applied in the field of the screening and feeding mechanism of irregular MIM molded products, can solve the problems of inability to use the feeding method and production troubles, and achieve the effect of ensuring integrity and avoiding mutual friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make it easier for those skilled in the art to understand the present invention, the specific implementation manners of the present invention will be described below with reference to the accompanying drawings.

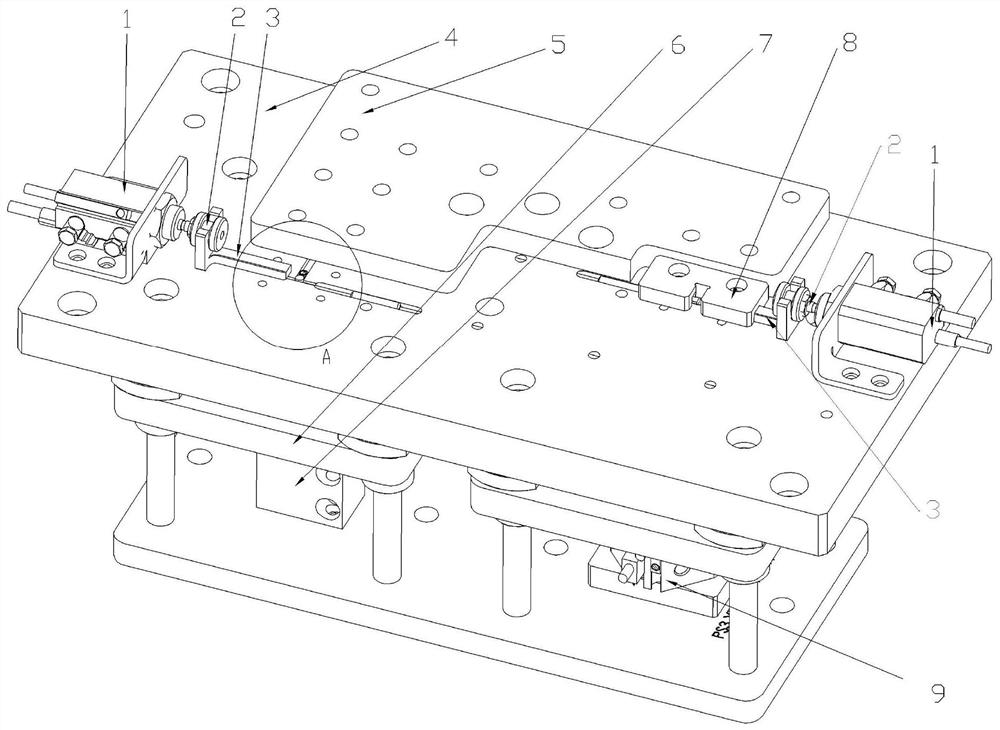

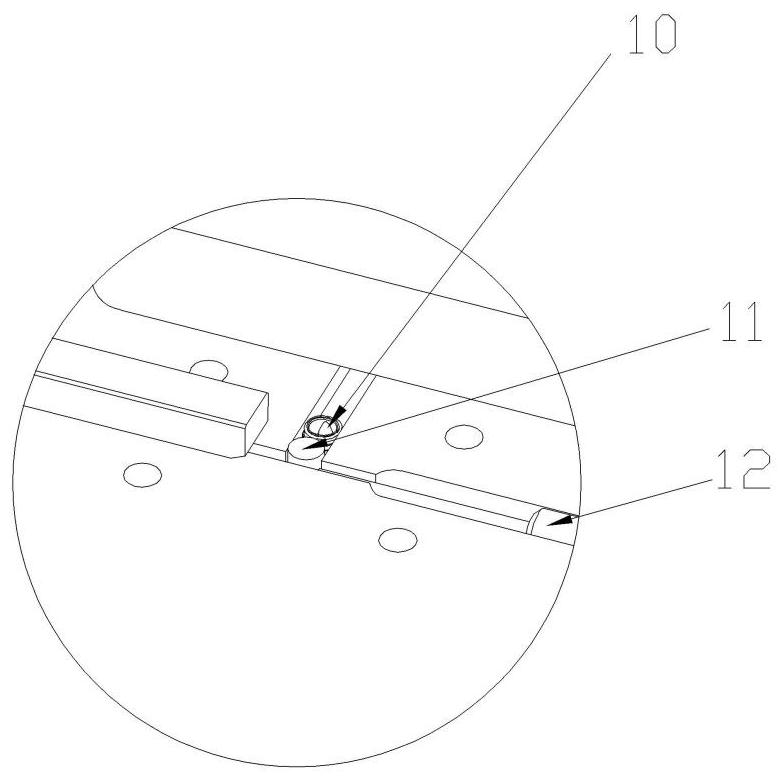

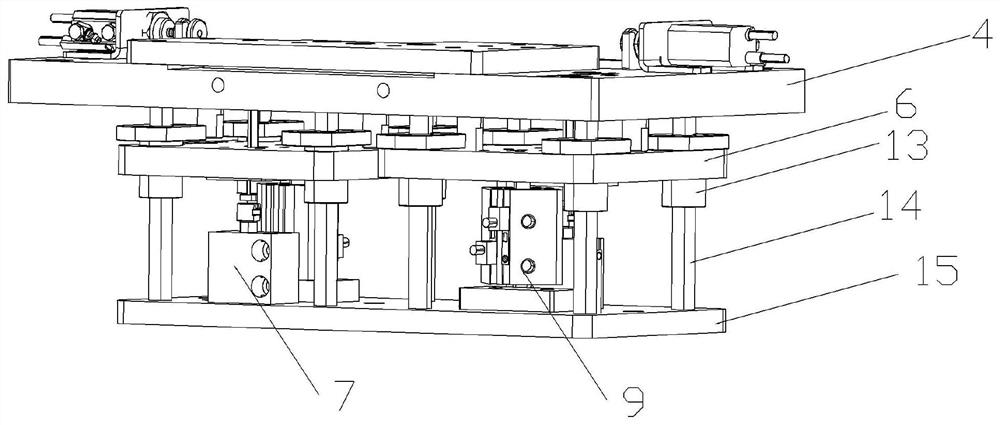

[0022] Such as Figure 1-4 As shown, a screening and feeding mechanism for irregular MIM molding products includes a feeder plate 4, an entire row of feeders, a limit thimble 10, a limit thimble cylinder 7, a thimble 11, a thimble cylinder 9, a discharge limiting mechanism and Fiber optic sensor 12 with model number FU-65X. The whole row of material channels is arranged on the material channel plate 4, the whole row of material channels is provided with the whole row of material channel cover plate 5, and the said whole row of material channels is provided with a discharge port. The position-limiting thimble 10 and thimble 11 are sequentially arranged at the discharge port and driven by the position-limiting thimble cylinder 7 and the thimble cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com