Intelligent detection balance lifting mechanical arm device

A lifting machinery and balancing technology, applied in the direction of manipulators, program-controlled manipulators, claw arms, etc., can solve the problems of mechanical arm device wear, low work efficiency, cumbersome motion control, etc., to achieve reduced wear, stable movement, and lifting work efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

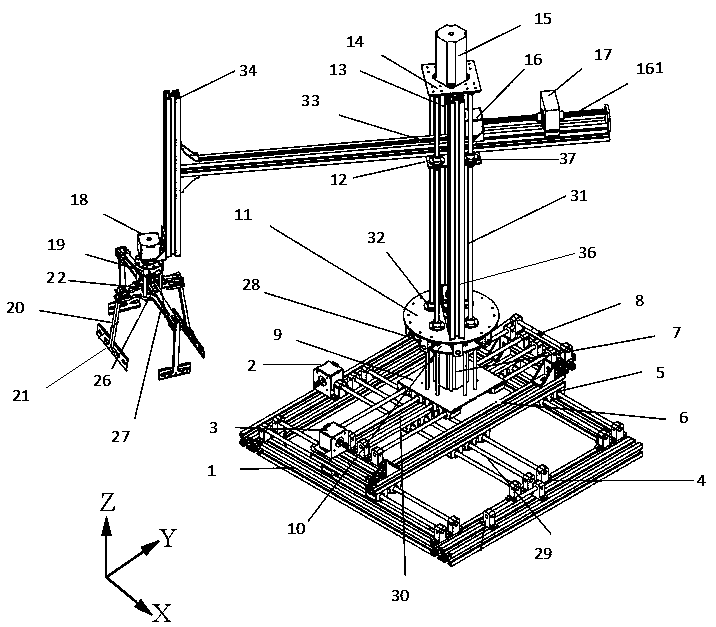

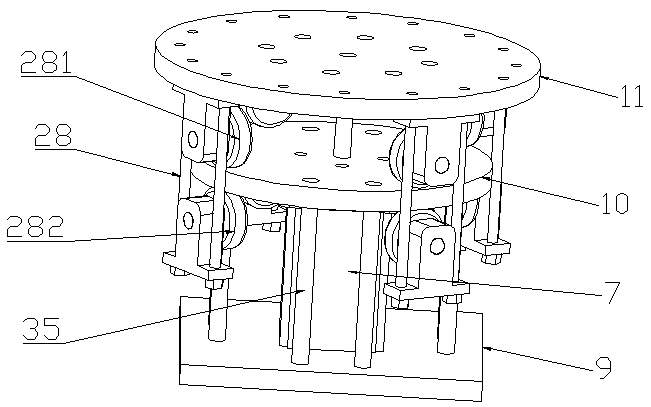

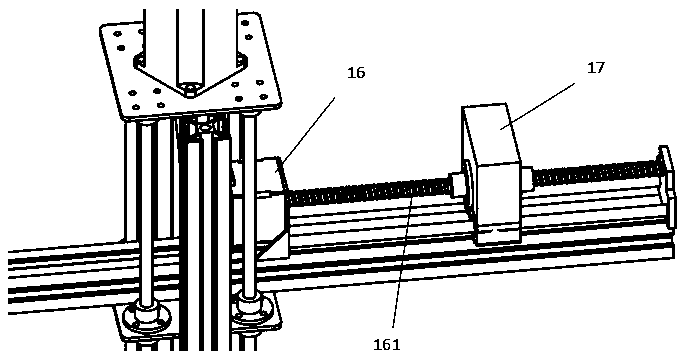

[0020] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0021] A kind of intelligent detection balance hoisting mechanical arm device, such as figure 1 As shown, the base 1 is included, the base 1 is an aluminum profile frame structure, and a plurality of X-direction optical axes 29 are set on the base 1. 29 is covered with a box-type slider 5, and the box-type slider is provided with a motion frame 6; the base 1 is also provided with a first stepping motor 2, and the first stepping motor 2 drives the motion frame 6 along the X through a synchronous belt. The direction moves relative to base 1;

[0022] On the moving frame 6, a Y-direction optical axis 30 is also arranged, and the Y-direction optical axis 30 is connected with the moving frame 6 through the Y-direction optical axis supporting base 8. The Y-direction optical axis 30 is covered with a box-type slider, and the box-type slider The fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com