A cloth shearing machine with adjustable cloth length

An adjustable cloth cutting machine technology, applied in the direction of thin material processing, sending objects, transportation and packaging, etc., can solve the problems of complex cutting requirements, low efficiency, and troublesome adjustment of cutting length, so as to improve the cutting efficiency and automation high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

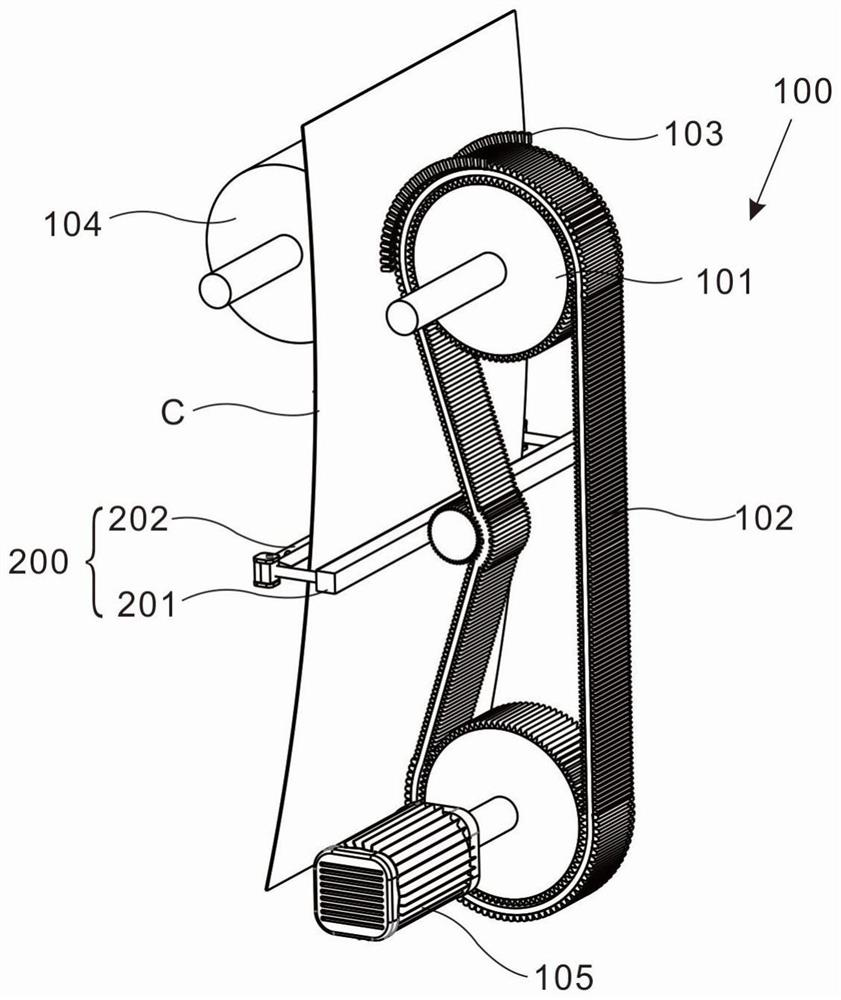

[0029] refer to Figure 1~3 , the first embodiment of the present invention provides a cloth trimming machine with adjustable cloth length, including a transmission assembly 100 and a cutting assembly 200, the transmission assembly 100 includes a gear 101, a toothed belt 102, a pressing block 103 and a cylinder 104 and the motor 105, the gear 101 meshes with the toothed belt 102, the pressing block 103 is connected to the side of the toothed belt 102, the pressing block 103 cooperates with the cylinder 104 to press the cloth C; the shearing assembly 200 includes the first shearing The member 201 and the second shearing member 202 , the first shearing member 201 and the second shearing member 202 can move relative to each other to cut the cloth C.

[0030] In an embodiment, the main body of the pressing block 103 is a cuboid, and its material is relatively hard, and generally can be made of other materials such as iron blocks or alloys; Cylindrical rotary parts for feeding, dr...

Embodiment 2

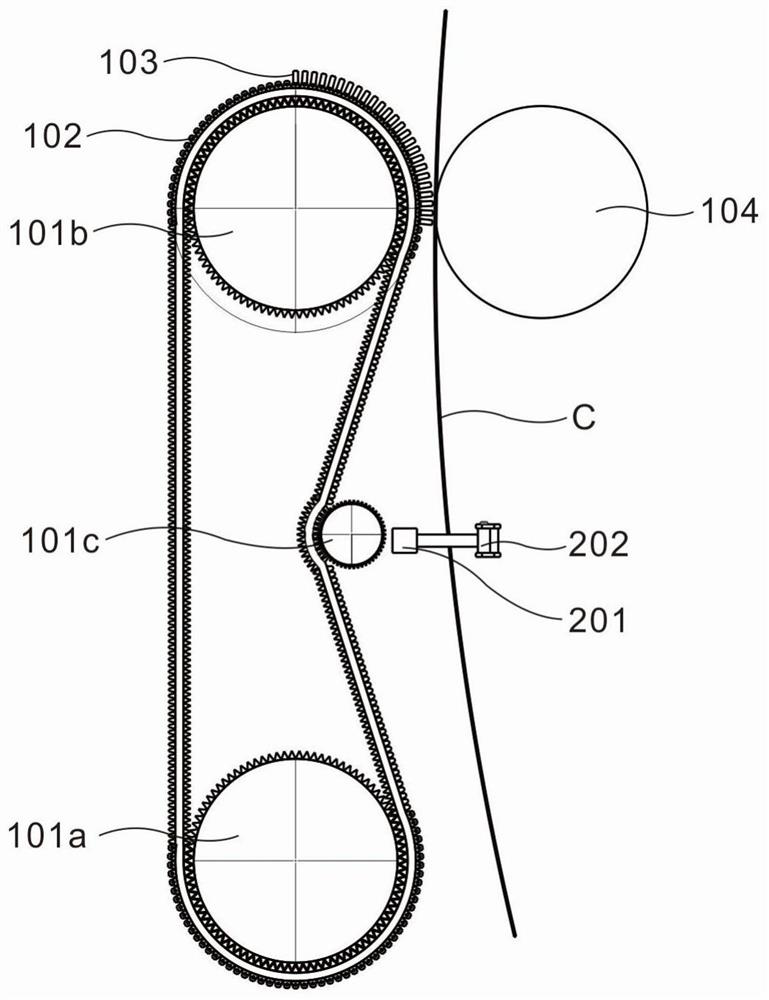

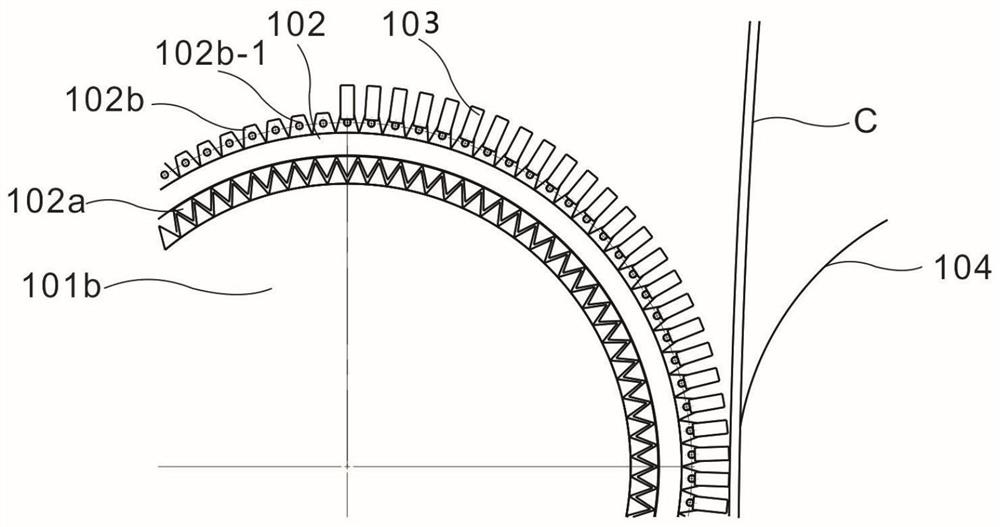

[0037] refer to Figure 4 , the second embodiment of the present invention provides a cloth trimming machine with adjustable cloth length, including a transmission assembly 100, a cutting assembly 200, and a transmission assembly 300, and the transmission assembly 100 includes a gear 101, a toothed belt 102, and a pressing block 103 and the cylinder 104 and the motor 105, the gear 101 meshes with the toothed belt 102, the pressing block 103 is connected to the side of the toothed belt 102, the pressing block 103 cooperates with the cylinder 104 to press the cloth C; the gear 101 includes the first gear 101a, the second gear 101b and the third gear 101c, the first gear 101a and the second gear 101b mesh with the toothed belt 102, and the motor 105 is connected with the first gear 101a. The toothed belt 102 includes internal teeth 102a and external teeth 102b, the internal teeth 102a mesh with the first gear 101a and the second gear 101b respectively, and the third gear 101c mes...

Embodiment 3

[0045] refer to Figure 5-7 , the third embodiment of the present invention provides a cloth trimming machine with adjustable cloth length, including a transmission assembly 100, a cutting assembly 200, and a transmission assembly 300, and the transmission assembly 100 includes a gear 101, a toothed belt 102, and a pressing block 103 and the cylinder 104 and the motor 105, the gear 101 meshes with the toothed belt 102, the pressing block 103 is connected to the side of the toothed belt 102, the pressing block 103 cooperates with the cylinder 104 to press the cloth C; the gear 101 includes the first gear 101a, the second gear 101b and the third gear 101c, the first gear 101a and the second gear 101b mesh with the toothed belt 102, and the motor 105 is connected with the first gear 101a. The toothed belt 102 includes internal teeth 102a and external teeth 102b, the internal teeth 102a mesh with the first gear 101a and the second gear 101b respectively, and the third gear 101c me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com