Three-dimensional interwoven composite bottom fabric and papermaking felt

A composite bottom and three-dimensional technology, applied in textiles and papermaking, papermaking, papermaking machines, etc., can solve the problems of affecting the water permeability of papermaking felts, shortening the service life of papermaking felts, and clogging gaps, etc., to achieve high resistance to high line pressure and speed up Fast, the effect of improving the ability to withstand high line voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

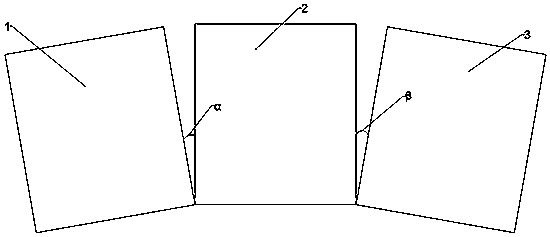

[0018] Such as figure 1 A three-dimensional interwoven composite base net is shown, including three layers of base net, which are stitched by needle punching machine. From top to bottom, there are ring weave base net 1, first twill weave base net 2, and second twill weave base net 3. The angle α between the weft of the adjacent ring-woven base net 1 and the weft of the first twill weave base net 2 is 12°, the weft of the first twill weave base net 2 and the weft of the second twill weave base net 3 The included angle β is 10°, and the included angle between two adjacent base nets ensures that the weft between the two base nets is not vertical during use, effectively preventing depression.

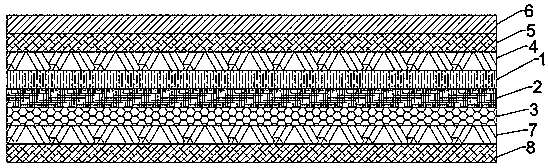

[0019] Such as figure 2 A papermaking felt shown, comprising figure 1 A three-dimensional interwoven composite bottom net formed by stitching three layers of base nets, a first bicomponent fiber layer 4 is arranged on the top of the three-dimensional interwoven composite bottom net, and ...

Embodiment 2

[0021] The structures of the three-dimensional interwoven composite bottom wire and papermaking felt in this embodiment are the same as those in Embodiment 1, wherein the included angle α is 5°, and the included angle β is 15°.

Embodiment 3

[0023] The structures of the three-dimensional interwoven composite bottom net and the papermaking felt in this embodiment are the same as those in Embodiment 1, wherein the included angle α is 2°, and the included angle β is 15°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com