Oil drain device of reciprocating pump

A technology of reciprocating pumps and oil drainers, which is applied in wellbore/well components, earthwork drilling, sealing/package, etc., which can solve the problem of high cost of use, oil drainers that cannot drain oil, and are not reusable and other issues, to achieve the effect of loose operating conditions and loose requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

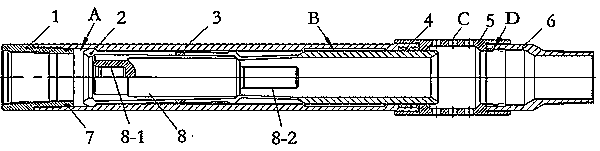

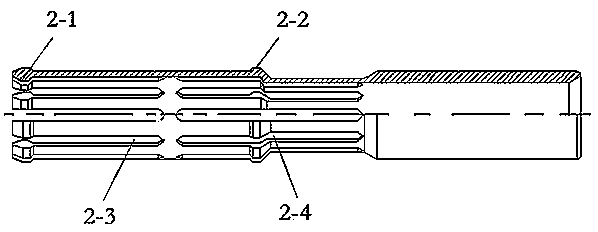

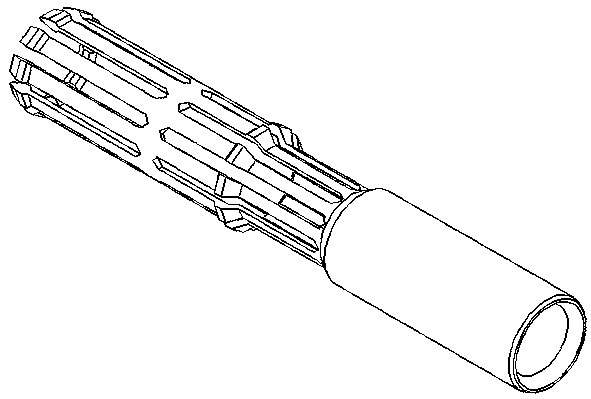

[0009] See Figure 1-3 The specific structure is as follows: the upper end of the upper joint 1 is provided with an internal thread for connecting the oil pipe, the upper outer sleeve 3 is threadedly connected with the lower end of the upper joint 1 and a sealing ring 7 is added, the upper inner diameter of the upper outer sleeve 3 is processed with a card groove A, and the lower inner diameter of the upper outer sleeve 3 is processed with a Slot B; the jaw 2 is milled with two sections of 10 equal gaps 8-1, 8-2 to make it flexible; the upper end of the jaw 2 is provided with an inner and outer boss 2-1, and the middle of the jaw 2 is provided with an outer protrusion Platform 2-2; claw 2 is placed inside the upper jacket 3, and the inner and outer bosses 2-1 on the upper end of the claw 2 are placed in the slot A of the upper jacket 3; the upper jacket 3 and the lower joint 6 are threaded to connect the lower jacket 5. Oil drain hole C is processed on the lower casing 5; a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com