Generation and control method of partial erasing voltage of liquid crystal writing film

A technology of erasing voltage and control methods, which is applied in electrical digital data processing, instruments, calculations, etc., can solve the problems of single voltage, loss of conductive layer, and inability to apply voltages to different conductive areas separately, so as to compensate for output voltage instability , improve business value, improve work efficiency and the effect of user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

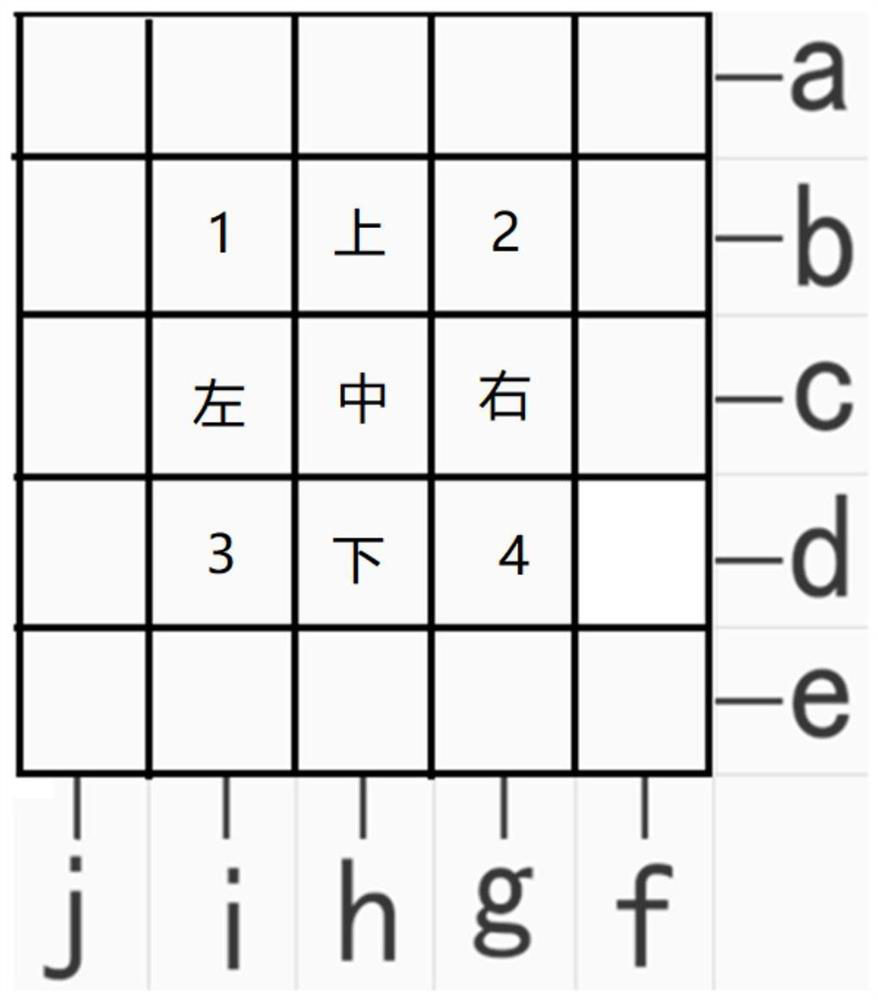

[0087] The embodiment of the present invention discloses a method for generating and controlling local erasing voltage of a liquid crystal writing film, wherein the liquid crystal writing film is located between two conductive layers, and the two conductive layers are respectively divided into two or more than two conductive regions ;

[0088] A voltage is applied to the conductive area of the first conductive layer covering the partially erased area; B voltage is applied to the conductive area of the second conductive layer covering the partially erased area; the A voltage and the B voltage are formed at the spatial overlapping position of the two conductive areas Erase the electric field to achieve local erasure.

[0089] Apply the C voltage to the set conductive areas outside the respective conductive areas of the two conductive layers covering the partially erased area, wherein the set conductive areas can be the respective conductive areas of the two conductive layers...

Embodiment approach

[0100] As a preferred implementation, we set:

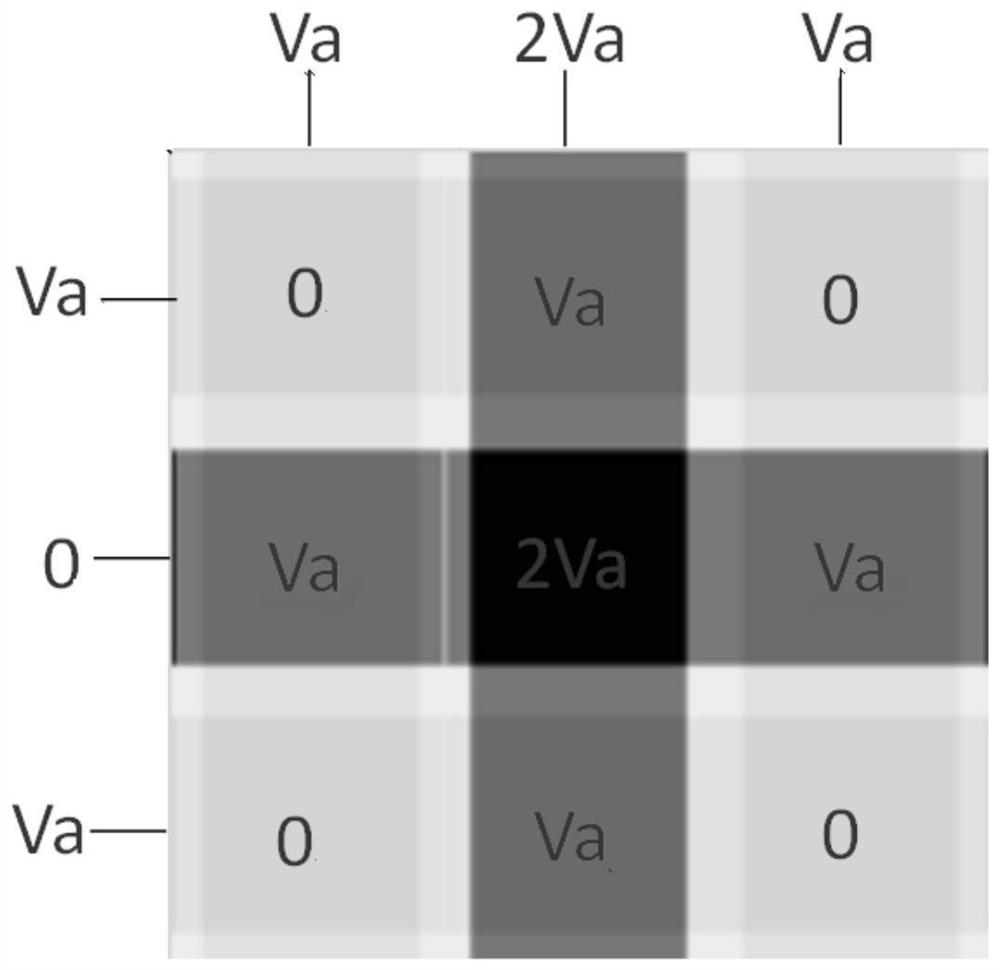

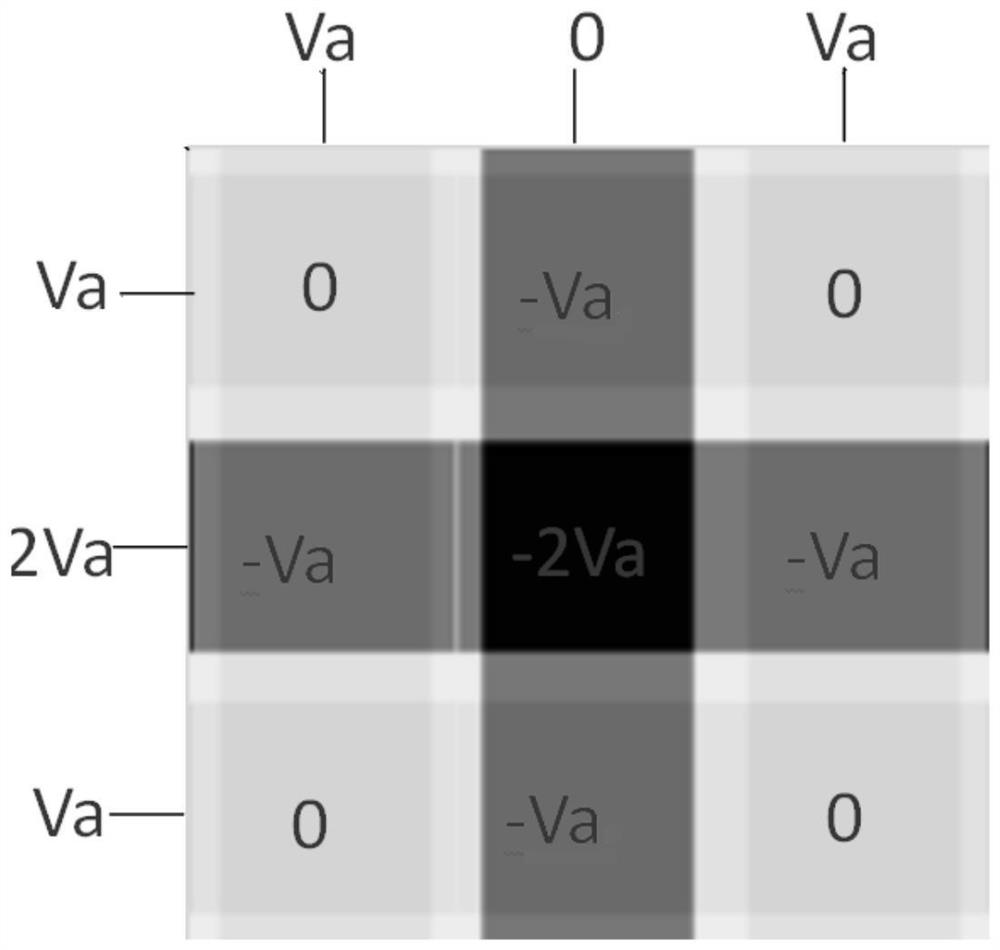

[0101] |Vh|=|Va|*2.

[0102] It should be noted that the applied voltages on the two conductive layers are exchanged every set time, so that the electric field formed on the entire liquid crystal writing film has the same magnitude but opposite direction, which can avoid the long-term damage to the liquid crystal writing film. The liquid crystal polarization phenomenon occurs due to the application of an electric field in the same direction. Hereinafter, we refer to the two time periods with different electric field directions as the first half and the second half, respectively.

[0103] The voltage applied to each conductive area of the writing film is as follows figure 1 or figure 2 shown. in, figure 1 is the voltage applied in the first half field of each conductive area of the writing film, figure 2 The voltage applied for the second half of each conductive area of the writing film; the order of supply voltages ...

Embodiment 2

[0108] The embodiment of the present invention discloses another method for generating and controlling the partial erasing voltage of the liquid crystal writing film, which overcomes the shortcomings of the control method in the second embodiment, and specifically includes:

[0109] The liquid crystal writing film is located between two conductive layers, and the two conductive layers are respectively divided into two or more conductive regions;

[0110]A voltage is applied to the conductive area of the first conductive layer covering the partially erased area; B voltage is applied to the conductive area of the second conductive layer covering the partially erased area; the A voltage and the B voltage are formed at the spatial overlapping position of the two conductive areas Erase the electric field to achieve local erasure.

[0111] Apply a D voltage to a conductive area set outside the conductive area on the first conductive layer covering the partial erasing area, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com