A preparation method and preparation device of dissolved gas in transformer oil

A technology of transformer oil and dissolved gas, which is applied in the field of transformer oil and can solve problems such as vacancies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

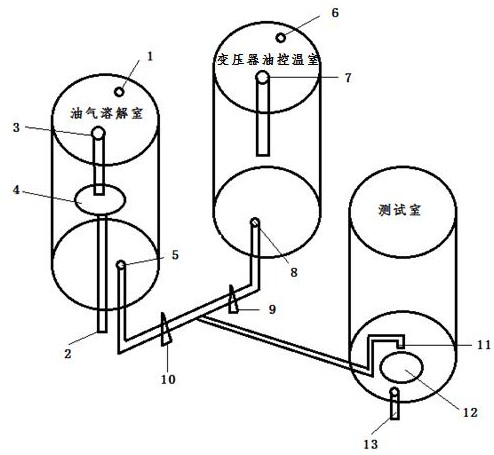

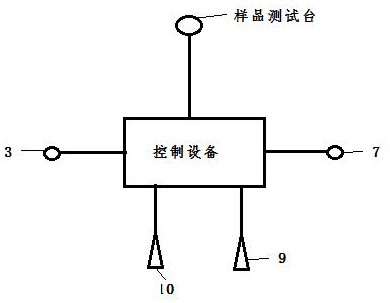

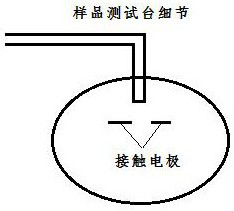

Image

Examples

Embodiment 1

[0038] This embodiment 1 provides a preparation method for dissolved gas in transformer oil, which is to take two parts of the same transformer oil a and b, feed gas into transformer oil a to make the gas in a reach saturation, and then make the gas in a and b The temperature is the same, combined with the Ostwald coefficient derived from Henry's law to control the flow ratio of the oil in a and b, and finally prepare the transformer oil with a specified dissolved gas concentration.

[0039] As a further refinement, the Ostwald coefficient is dependent on temperature and its formula is:

[0040]

[0041] : actual temperature;

[0042] : Ostwald coefficient of oil at 273K;

[0043] : The density of oil at 288K;

[0044] calculated for temperature The Ostwald coefficient at , so the dissolved gas concentration in the final formulated oil:

[0045]

[0046]

[0047] : gas concentration in the oil (%);

[0048] : Actual flow rate of oil outlet hole in sa...

Embodiment 2

[0070] The purpose of Example 2 is to prepare transformer oils with dissolved gas concentrations in No. 10 transformer oil of 350 ppm, 480 ppm and 640 ppm under the condition of 80°C.

[0071] The specific operation process of this embodiment 2 is the same as that of embodiment 1.

[0072] The final calculation shows that when the dissolved gas concentrations in the transformer oil are 350ppm, 480ppm and 640ppm respectively, the flow control ratios in the oil-gas dissolution chamber and the transformer oil control greenhouse are respectively , and .

Embodiment 3

[0074] The purpose of Example 3 is to prepare transformer oils with dissolved gas concentrations of 50 ppm and 200 ppm in No. 25 and No. 45 transformer oils under the condition of 80° C., respectively.

[0075] The specific operation process of this embodiment 3 is the same as that of embodiment 1.

[0076] Finally, the flow control ratios in the oil-gas dissolution chamber and transformer oil control greenhouse of No. 25 transformer oil and No. 45 transformer oil are calculated as and .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com