Ship water lubricating propeller bearing capable of controlling transverse dynamic excitation of shaft system propeller

A dynamic excitation, propeller shaft technology, applied in ship propulsion, ship components, ship construction, etc., can solve the problems of weak restraint, large bearing running clearance, unfavorable shafting lateral vibration control, etc. Friction coefficient and wear rate, effect of promoting hydrodynamic lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

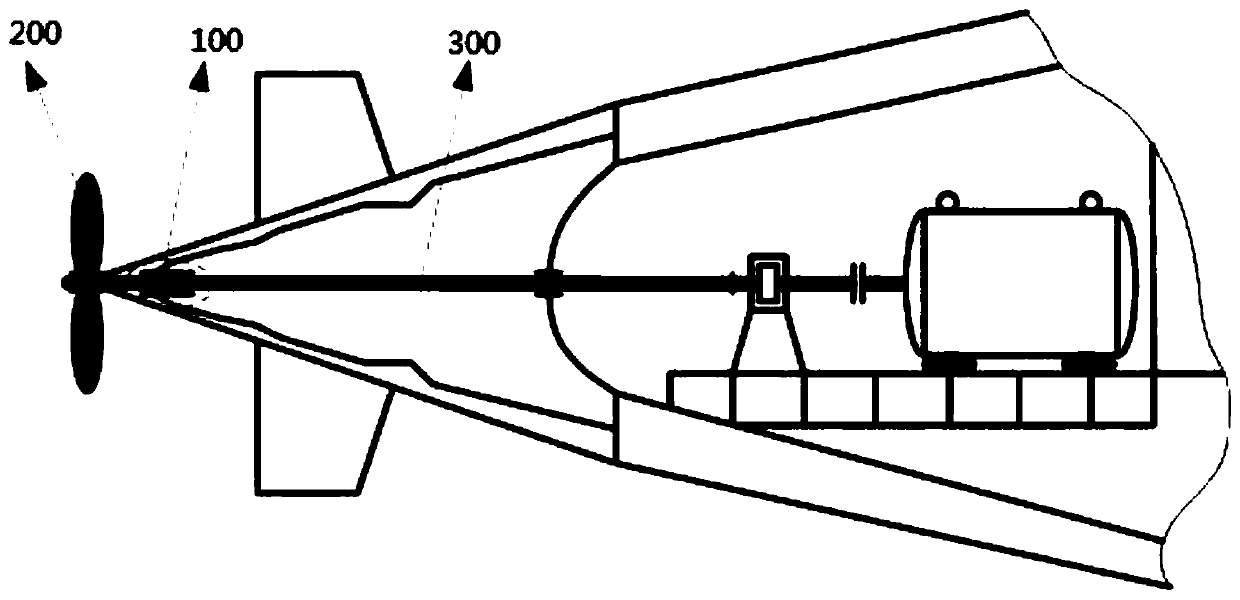

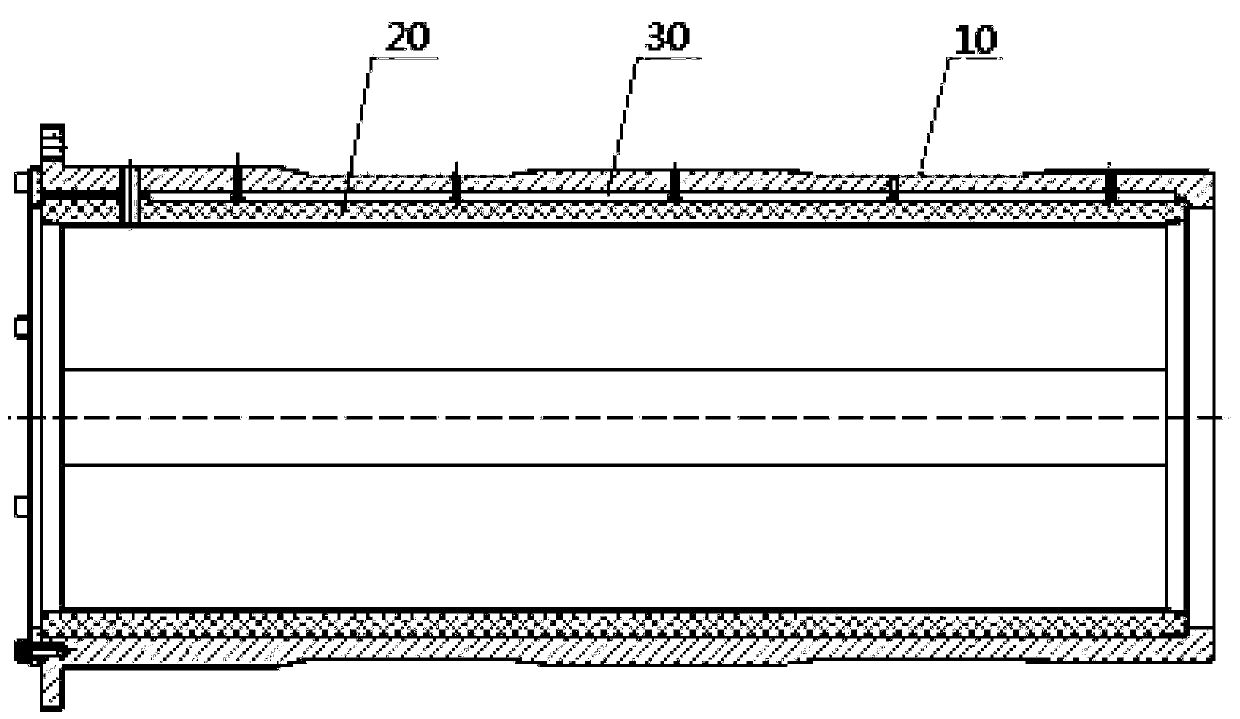

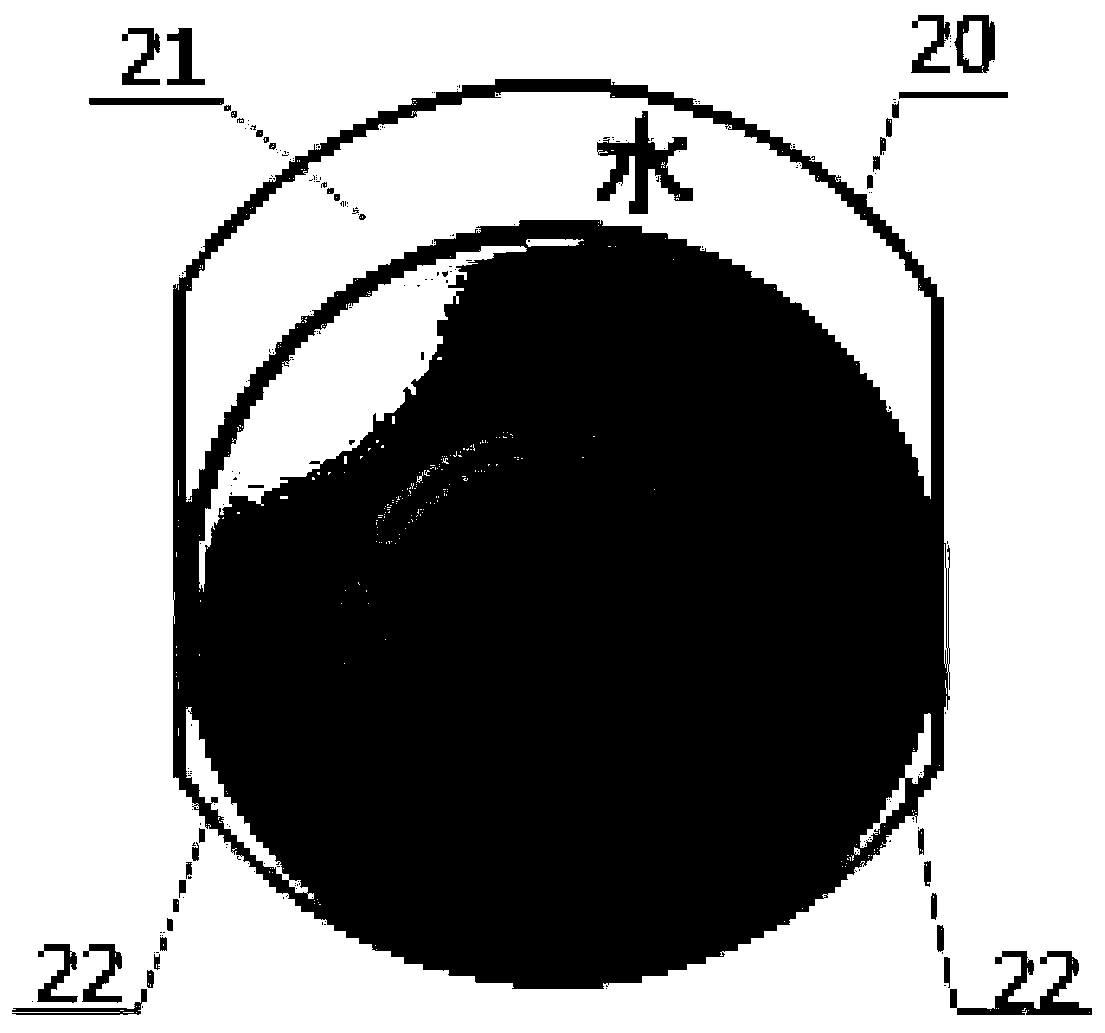

[0025] Such as figure 1 As shown, the ship water-lubricated propeller bearing 100 of the present invention that can control the lateral dynamic excitation of the shafting propeller is installed at the rear end of the propeller shaft 300 and the front end of the propeller 200 . Such as figure 2 As shown, the propeller bearing 100 includes a shell 10 and a bearing bush 20 installed in the shell 10 , the shell 10 of the propeller bearing 100 is connected with the inner hole of the hull structure, and the shell 10 is made of steel or copper alloy. The propeller shaft 300 passes through the bearing bush 20 of the propeller bearing 100 , and is seated in the bearing area of the lower half of the bearing bush 20 .

[0026...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com