Directional device of photoelectric tracker installed on naval gun bracket

A photoelectric tracker and azimuth technology, applied in the direction of control using feedback, can solve the problems of increasing the complexity of the structure, the volume and weight of the device, affecting the tracking accuracy of the servo control performance system, and requiring high axial dimensional accuracy, etc., to achieve improvement Mechanical properties and bending resistance, ensuring dynamic tracking accuracy, and the effect of no assembly stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

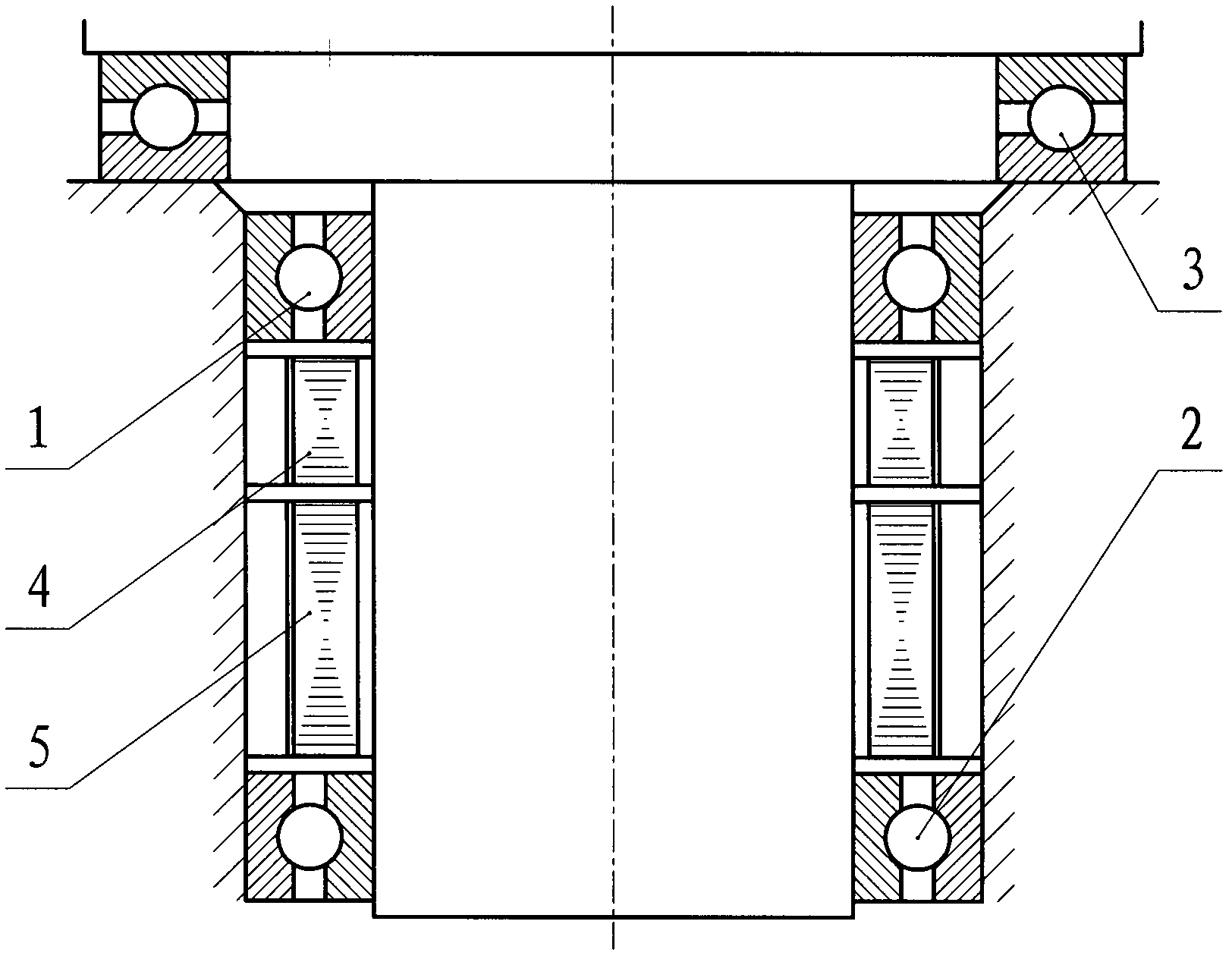

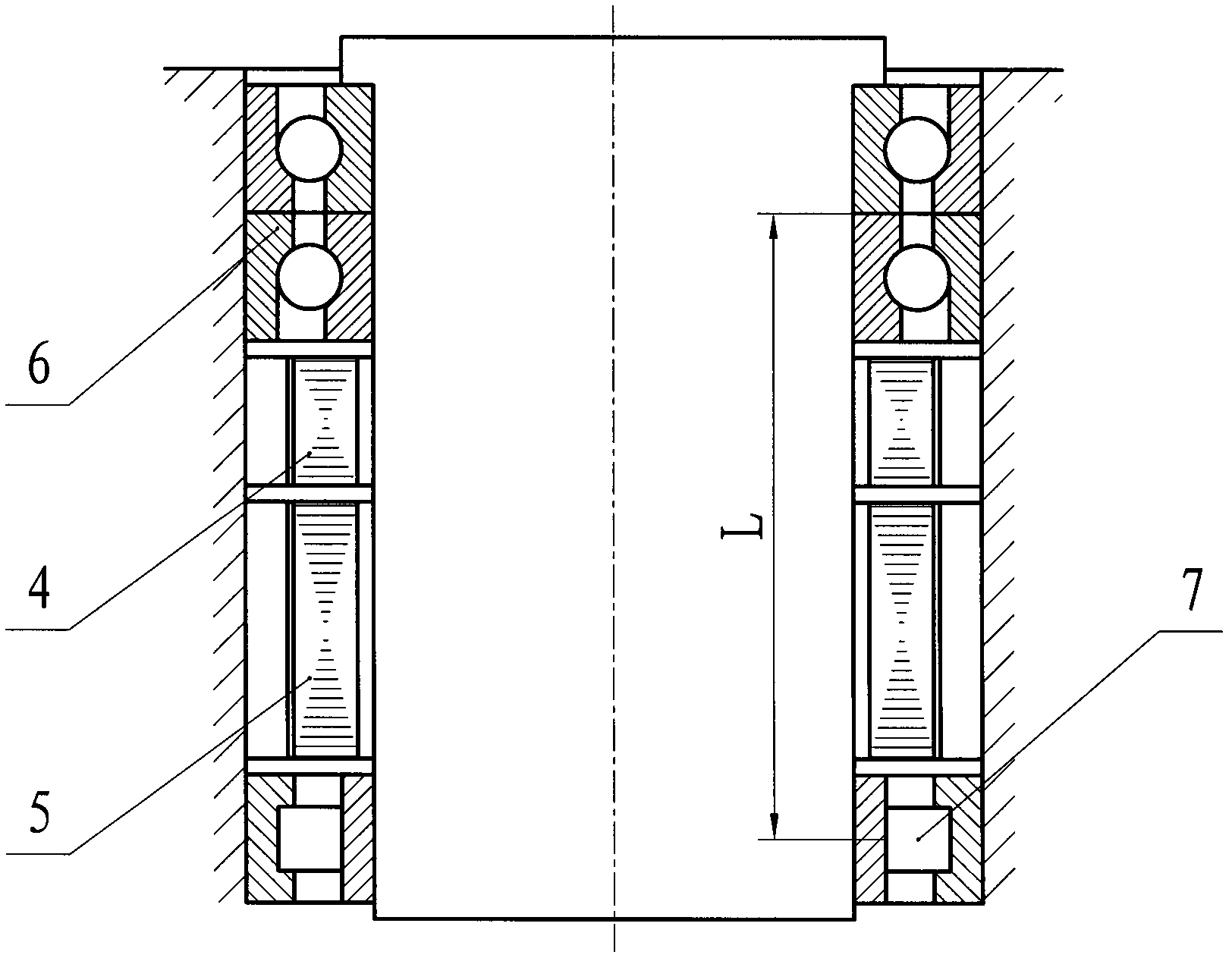

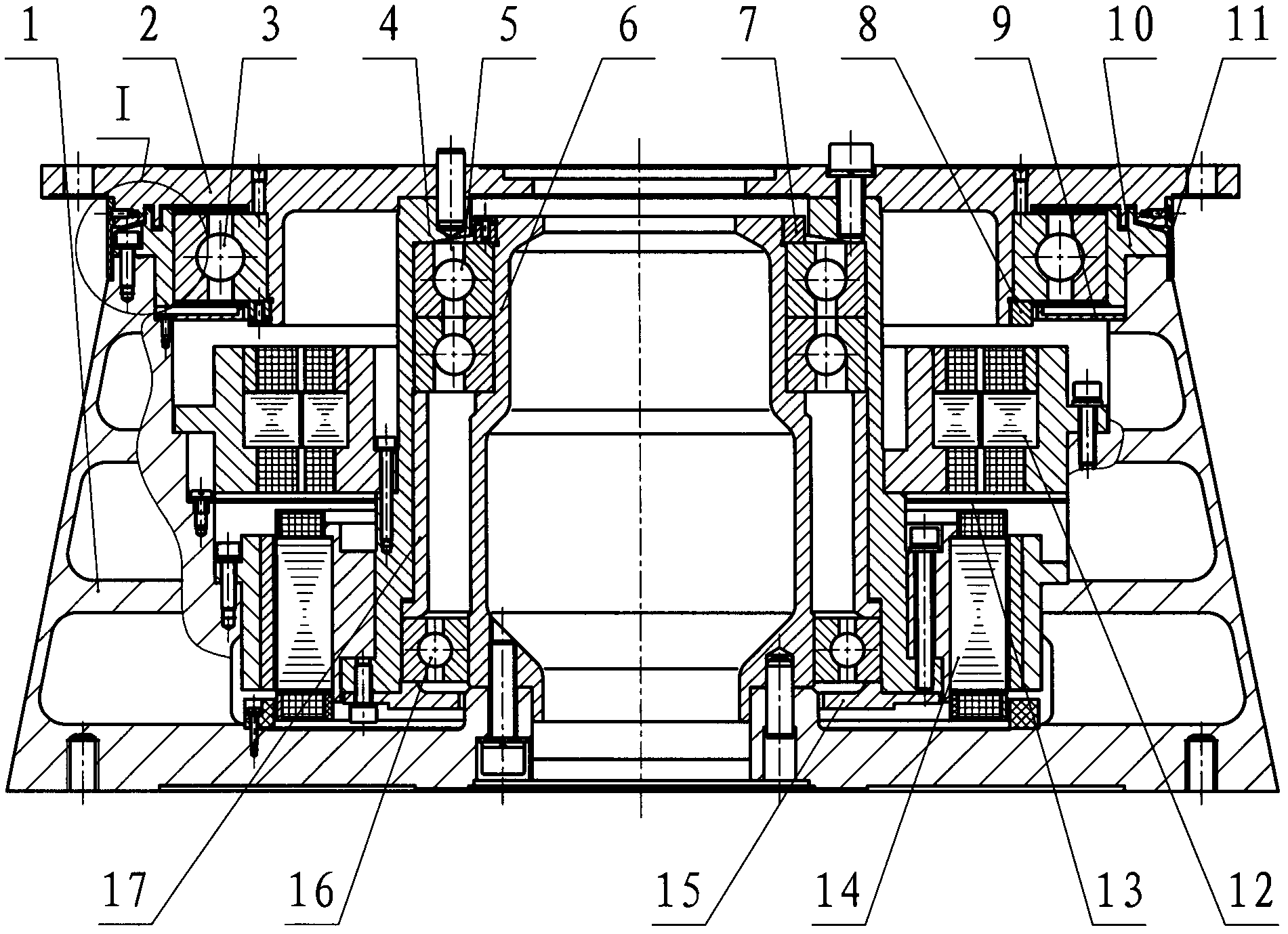

[0016] as image 3 As shown, the azimuth device provided by the preferred embodiment of the present invention includes a stationary part including an azimuth base 1, a bearing adapter seat 10 and an inner bearing seat 6, a rotating part including the azimuth coupling plate 2 and the azimuth shaft 4, and the space between the two A plurality of bearings, resolver 12 and torque motor 14 are connected. The azimuth base 1, the bearing adapter 10, the inner bearing seat 6, the azimuth connecting plate 2 and the azimuth shaft 4 all have a central through hole for installing a conductive slip ring or inserting a cable, so as to realize the direction of the load electrical signal at the upper end of the azimuth device. transmission at the bottom. For the stationary part, the inner bearing seat 6 is fixedly connected in the central through hole of the azimuth base 1 , the bearing adapter 10 is sleeved on the upper section of the inner bearing seat 6 with a large gap and the outer side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com