A differential filling device for metal powder bagging

A technology of powder bagging and differential filling, which is applied in the field of differential filling devices for metal powder packaging, which can solve the problems of difficult differential filling and large filling volume errors, and achieve high filling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

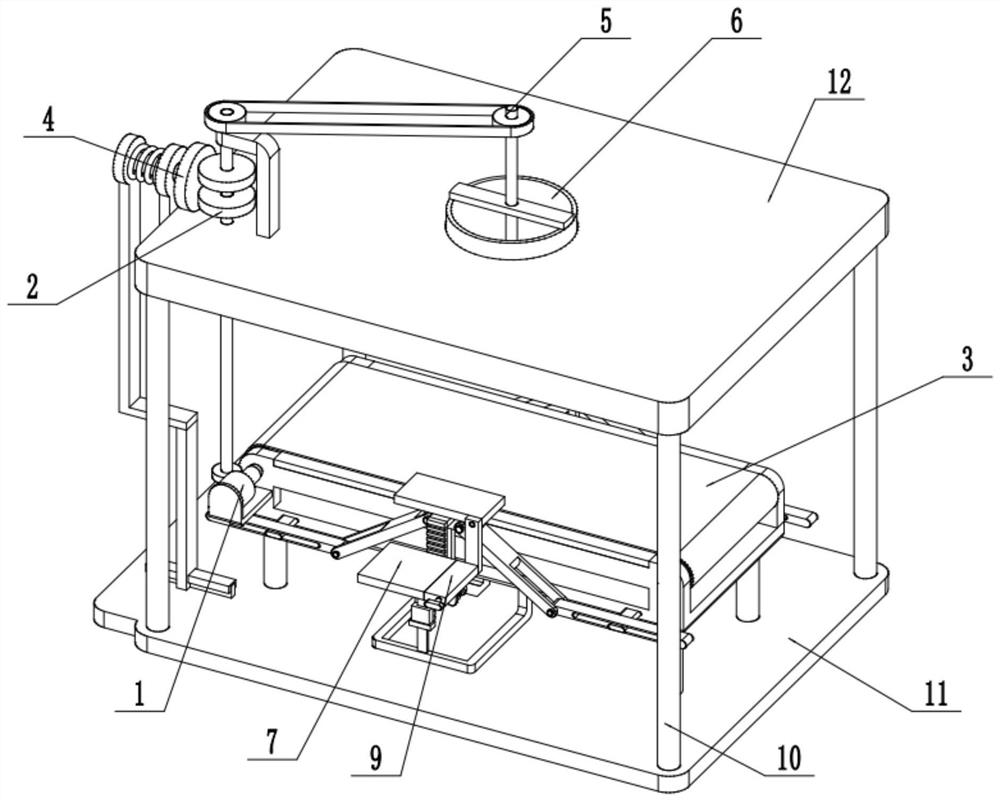

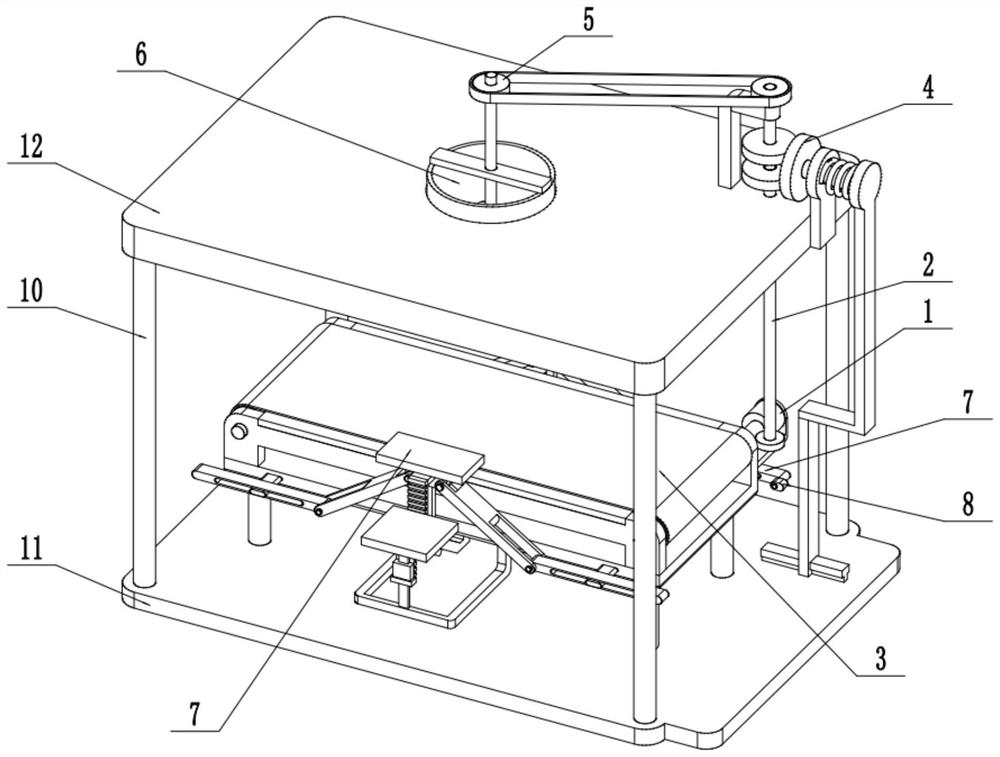

[0033] Such as Figure 1-13As shown, a differential filling device for metal powder bagging includes a driving mechanism 1, a linkage wheel 2, an output belt 3, a material control linkage 4, a feeder 5, a feeding cylinder 6, a differential balance mechanism 7, Interrupt the top plate 8, the upper seat plate 12, the support column 10 and the lower seat plate 11, the drive mechanism 1 is fixed on the output belt 3, and the drive mechanism 1 is connected to the output belt 3 and the linkage wheel 2; the output belt 3 is fixed on the lower seat on the plate 11; the linkage wheel 2 is rotatably connected to the upper seat plate 12, the linkage wheel 2 is connected to the material control linkage 4 by transmission, and the upper and lower ends of the material control linkage 4 are respectively fixedly connected to the upper seat plate 12 and the lower seat plate 11; The material control linkage 4 is connected to the feeder 5 through transmission, and one end of the feeder 5 is fixed...

Embodiment 2

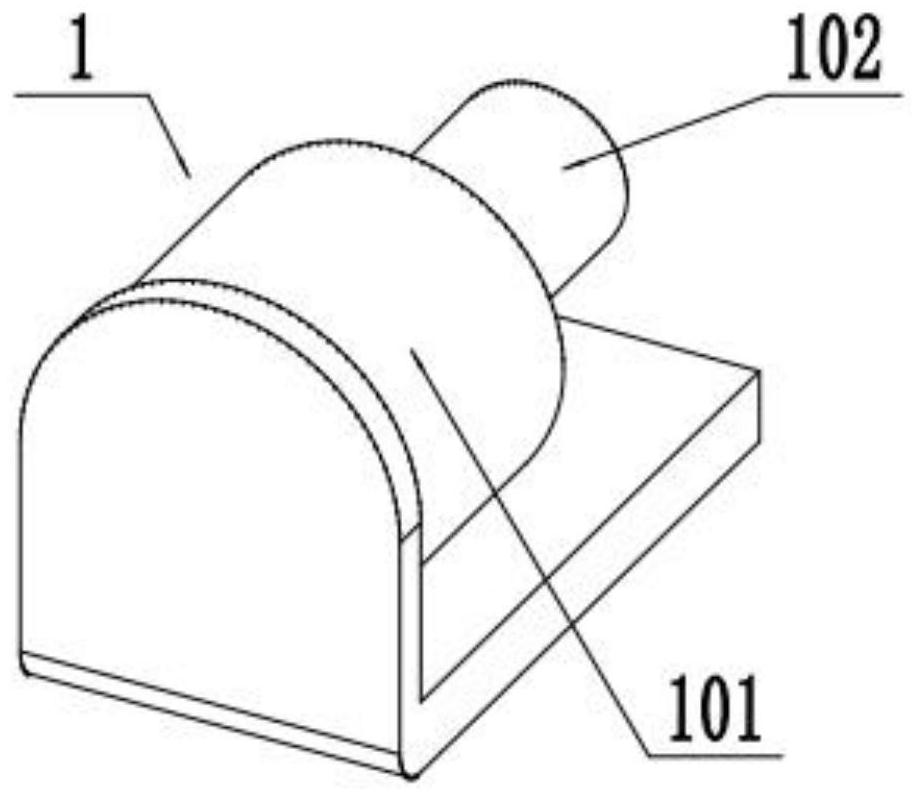

[0035] Such as Figure 1-13 As shown, the drive mechanism 1 includes a servo motor 101 and a worm 102 fixed on the output shaft of the servo motor 101; the servo motor 101 is fixed on the output belt 3 through a motor base; the worm 102 is connected to the output belt 3 and Linkage wheel 2. The servo motor 101 can drive the worm screw 102 to rotate around its own axis after being powered on and turned on, and the output belt 3 and the linkage wheel 2 can be driven to start working when the worm screw 102 rotates.

Embodiment 3

[0037] Such as Figure 1-13 As shown, the linkage wheel 2 includes a worm wheel 201, a first rotating shaft 202 and a friction transmission wheel 203; the middle part of the first rotating shaft 202 is rotatably connected to the upper seat plate 12; the upper and lower ends of the first rotating shaft 202 are respectively fixed The friction transmission wheel 203 is connected to the worm wheel 201; the worm 102 is meshed with the worm wheel 201; the friction transmission wheel 203 is connected to the material control linkage 4 through friction transmission. The worm wheel 201 rotates under the drive of the worm screw 102. The rotation of the worm wheel 201 drives the first rotating shaft 202 to rotate around its own axis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com