Kitchen waste pipe chain transmission line and kitchen waste treatment system using same

A food waste and treatment system technology, applied in conveyors, vertical pipelines, transportation and packaging, etc., can solve the problems of high price, strong smell, and unacceptable kitchen space, and achieve long transmission length and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Further illustrate the present invention by accompanying drawing below,

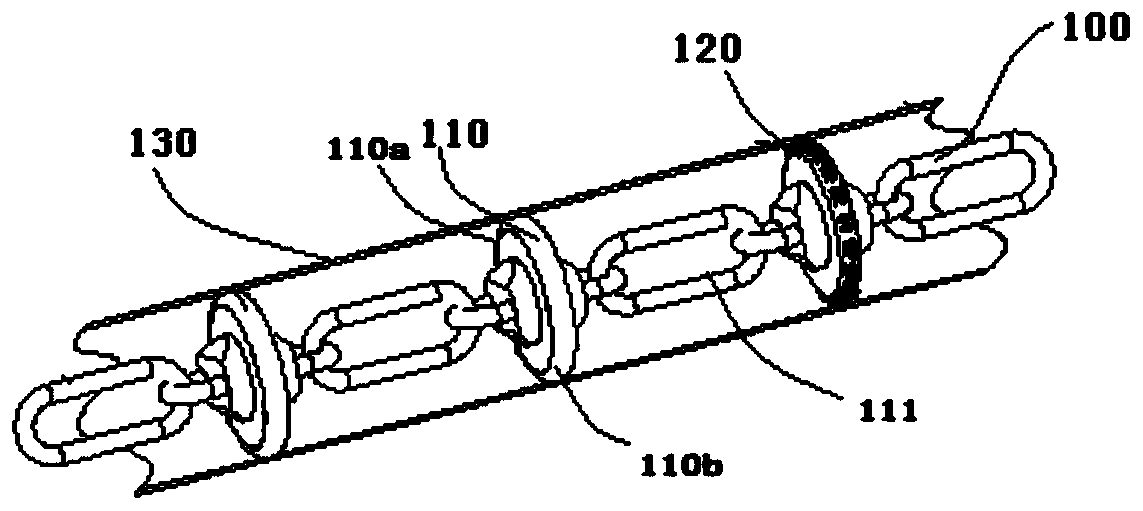

[0047] see figure 1, the food waste conveying pipe chain 100 is formed by a plurality of chain discs 110 and a plurality of chain links 111 interlaced and connected in series, and the outer diameter 110a of each chain disc 110 and the inner diameter 130a of the conveying pipe 130 are dynamically and tightly matched.

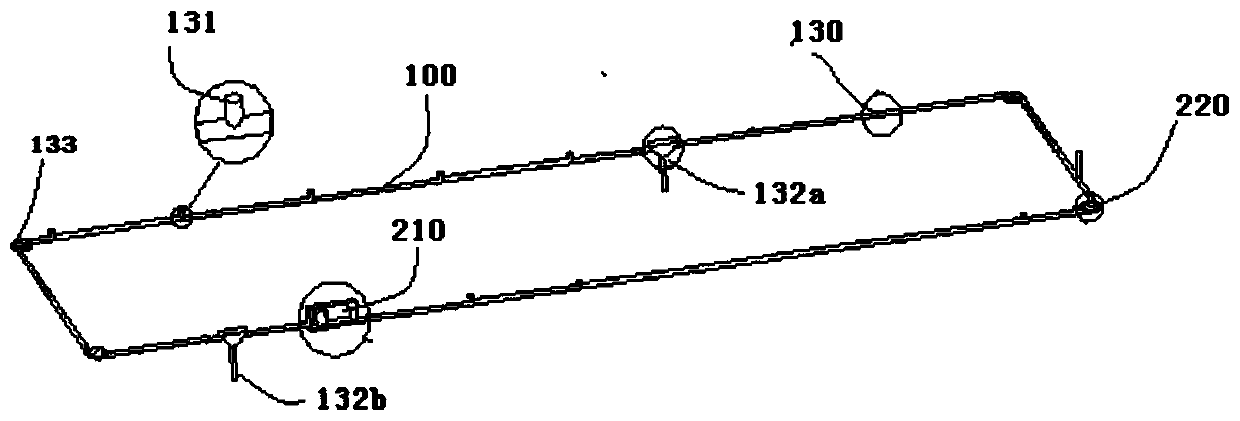

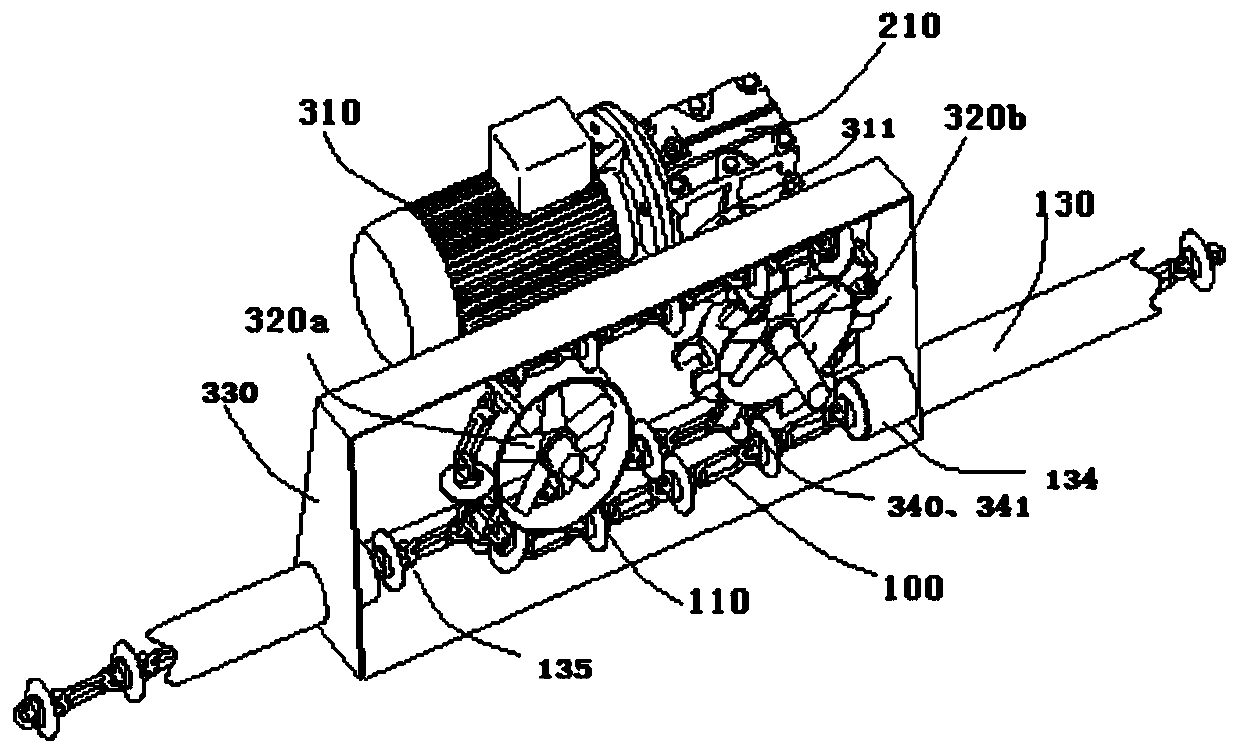

[0048] And the outer diameter 110a of each chain plate 110 is provided with a polyurethane sealing ring 110b, and the outer diameter of the polyurethane sealing ring 110b is in a dynamic and sealing fit with the inner diameter 130a of the delivery pipe 130 . And brushes 120 are provided on the outer diameters 110 a of some of the chain disks 110 . And the pipe chain 100 itself is made of stainless steel 304 material, which has sufficient strength and corrosion resistance. The PVC waterproof conveying pipe 130 in the horizontal pipe chain transmission line is laid along the wall or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com