Product boxing and stacking machine

A stacker and cartoning technology, applied in packaging and other directions, can solve the problems of consuming a lot of human resources, the transmission mechanism cannot adjust the transmission distance, and the assembly line cannot cooperate normally.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

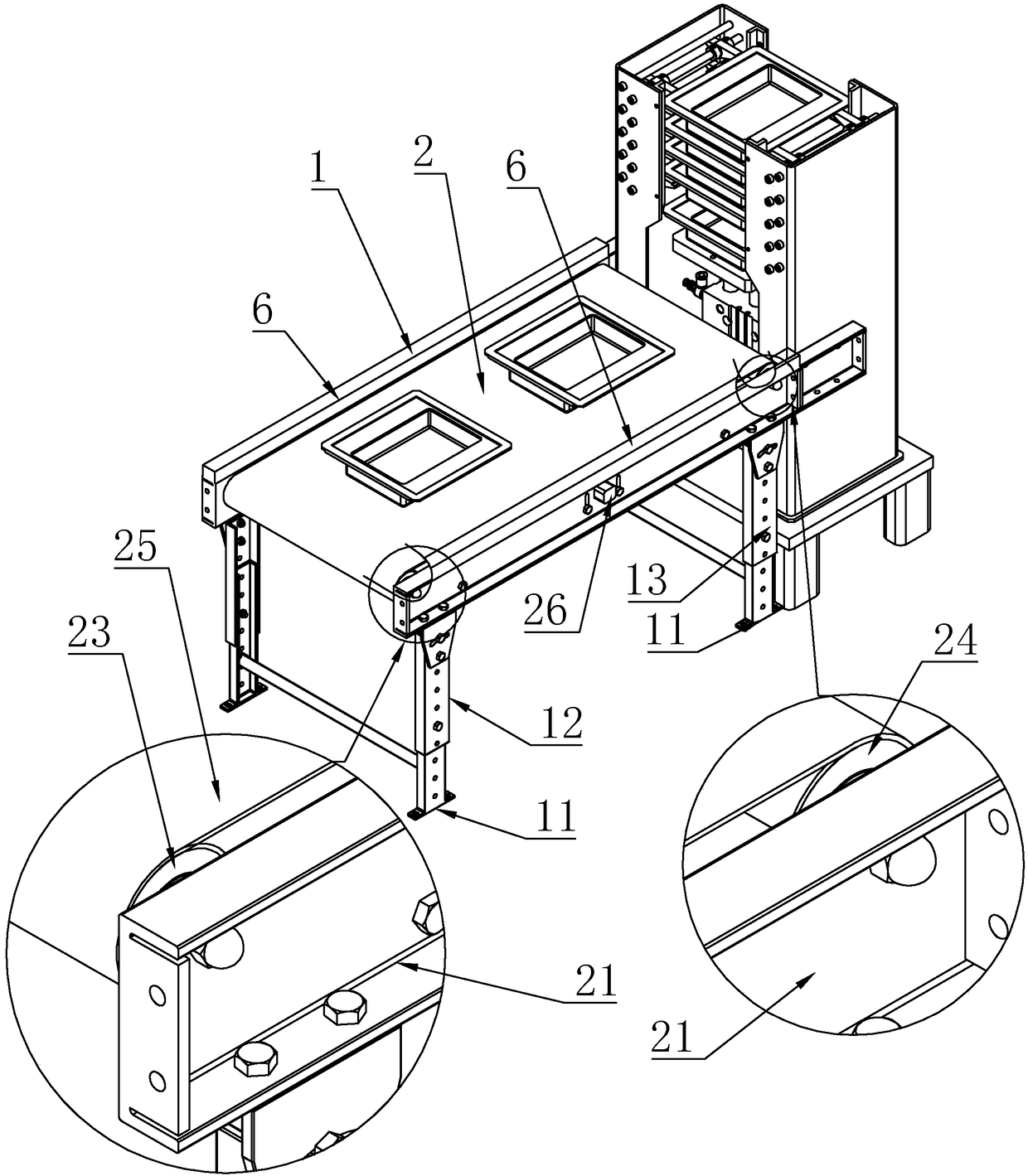

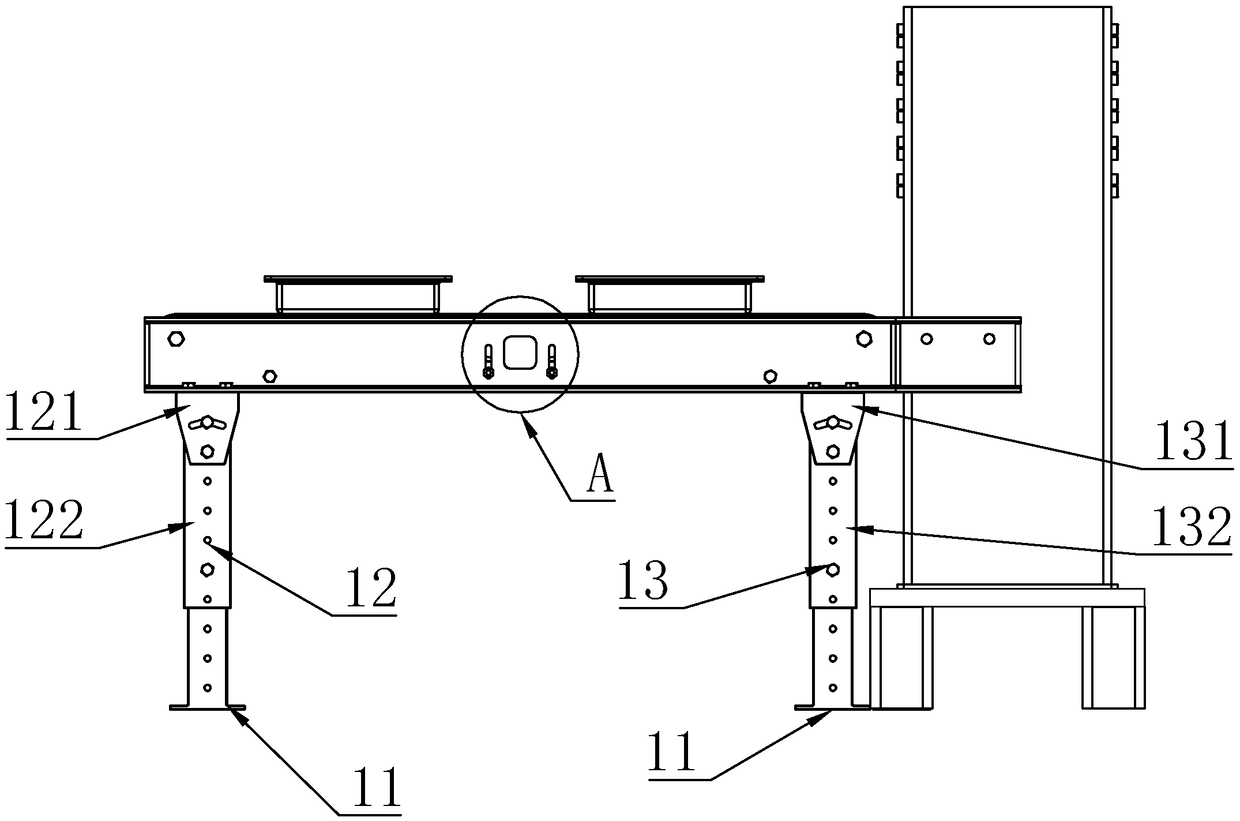

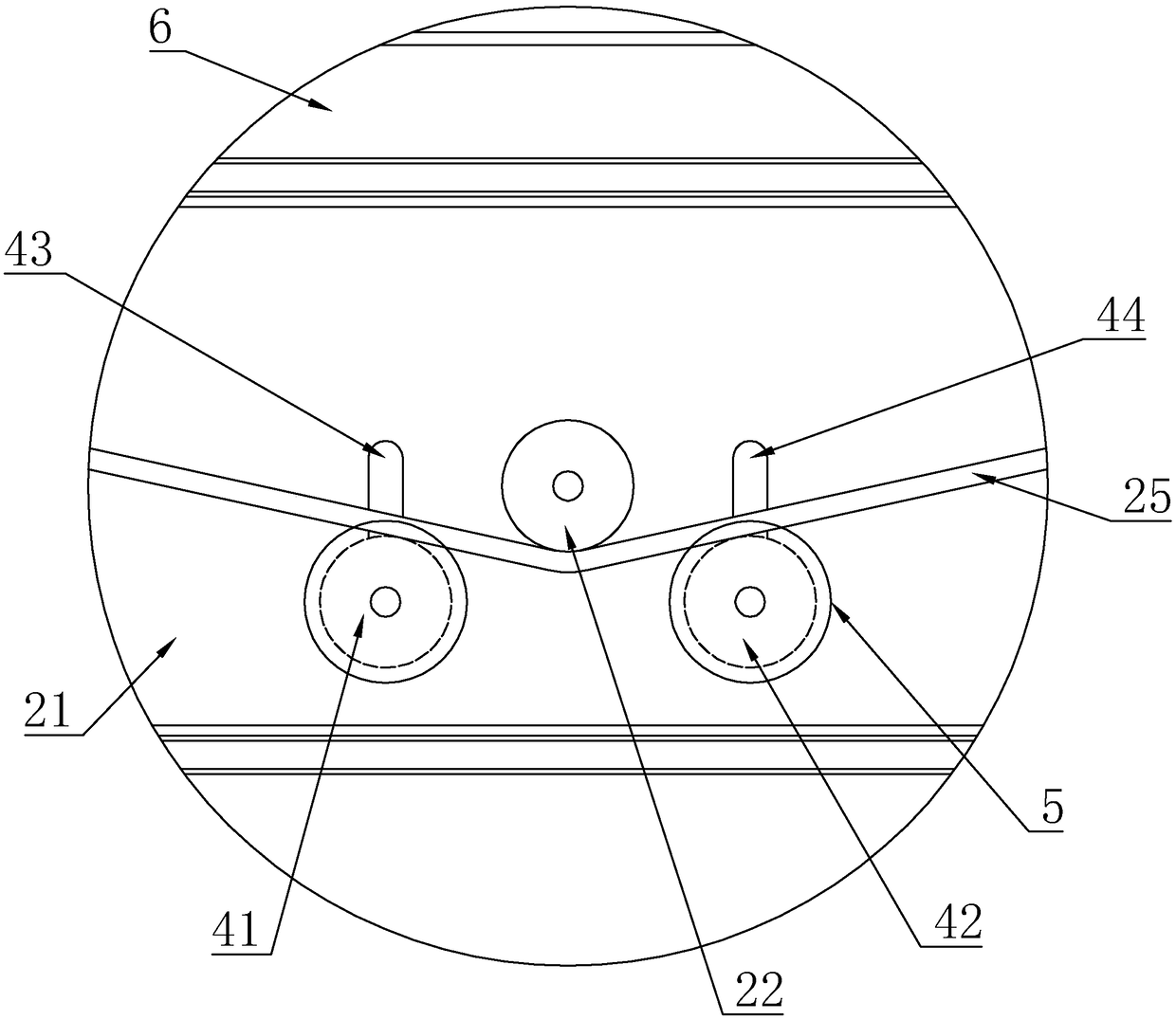

[0021]As an improved specific embodiment, the first mounting frame 12 includes a first connecting piece 121 and a first connecting rod 122, and the second mounting frame 13 includes a second connecting piece 131 and a second connecting rod 132, so The first connecting piece 121 and the second connecting piece 131 are installed on the two ends of the mounting plate 21 respectively, and the first connecting piece 121 can also be detachably connected to the first connecting rod 122, and the second connecting piece 131 can also be The connection is disassembled on the second connecting rod 132, and the ends of the first connecting rod 122 and the second connecting rod 132 that are far away from the first connecting member 121 and the second connecting member 131 are fixedly connected to the fixing base 11, and the The first connecting member 121 is provided with a first fixing hole 1211 and a first arc-shaped hole 1212 centered on the first fixing hole 1211, and the second connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com