Automatic reverse winding mechanism of magnetic tape recorder

An automatic reversing and tape recorder technology, which is applied in the direction of operation and control of filamentary/network carriers, can solve the problems of inability to achieve miniaturization and increased friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments are described below.

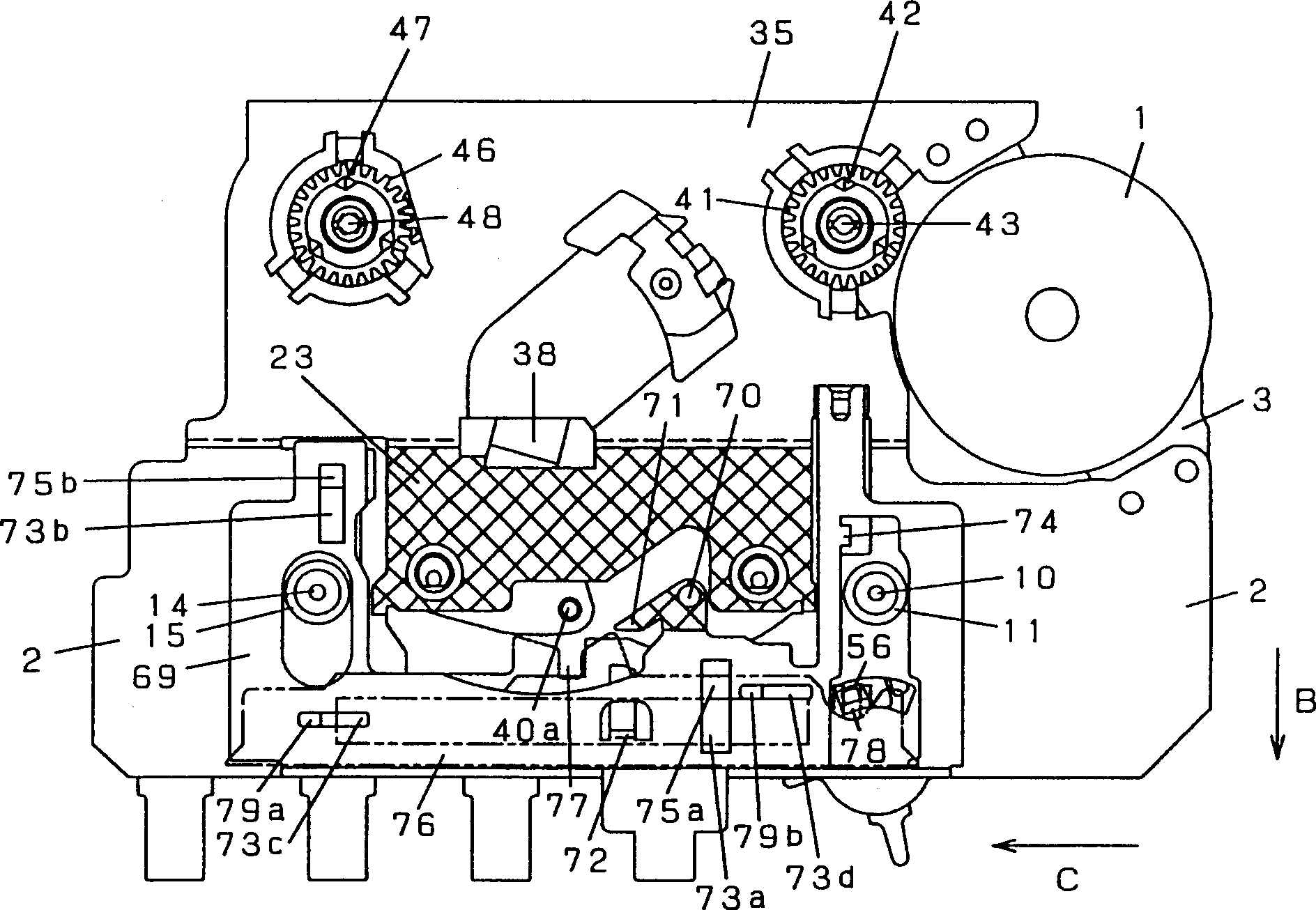

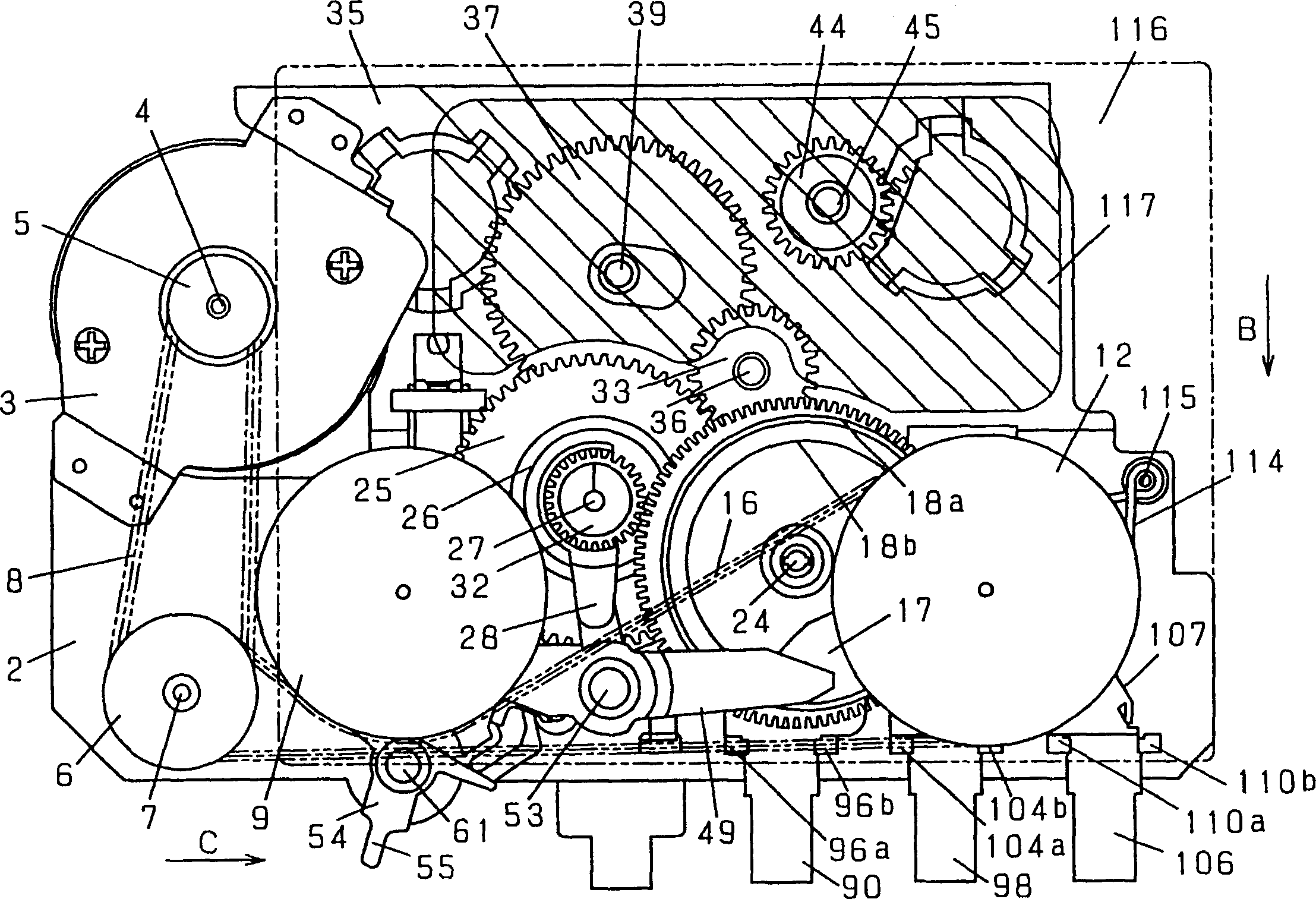

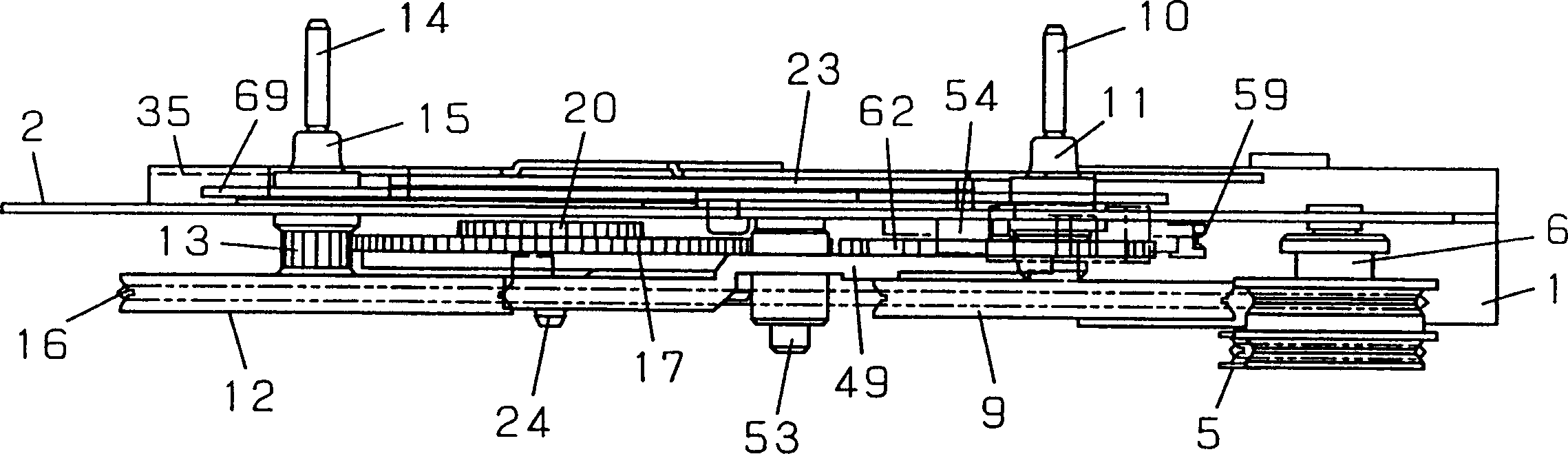

[0027] figure 1 It is a top view of a partial appearance of a magnetic tape recorder in one embodiment of the present invention, figure 2 is the back view of the appearance of the figure, image 3 is the partial exterior front view of the figure, Figure 4 is the partial appearance rear view of the figure, Figure 5 To mainly show the rear view of the electric motor power transmission system, Image 6 A rear view mainly showing the mechanical action system, Figure 7 for figure 2 Partial left view of , where (a) shows the stopped state, (b) shows the playing state, and the illustration shows the state without a cassette tape.

[0028] In the figure, 1 is a motor, which is fixed to a motor holder 3 fixed to a main board 2 with screws. A motor pulley 5 is press-fitted and fixed to the top end of the rotating shaft 4 of the motor 1 . 8 is a belt A, which straddles between the above-mentioned motor pulley 5 and a V-shaped groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com