Intelligent spouting system and spouting support method thereof

A shotcrete and intelligent technology, which is applied in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problems that shotcrete quality depends on operators and the shortage of skilled operators, so as to achieve the effect of improving efficiency and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

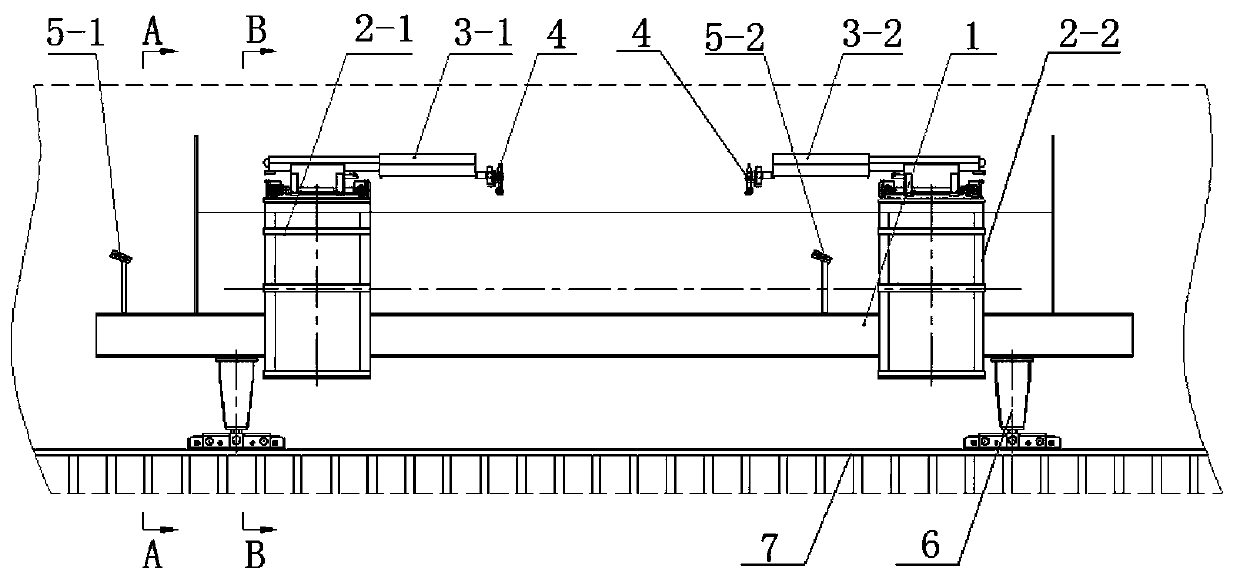

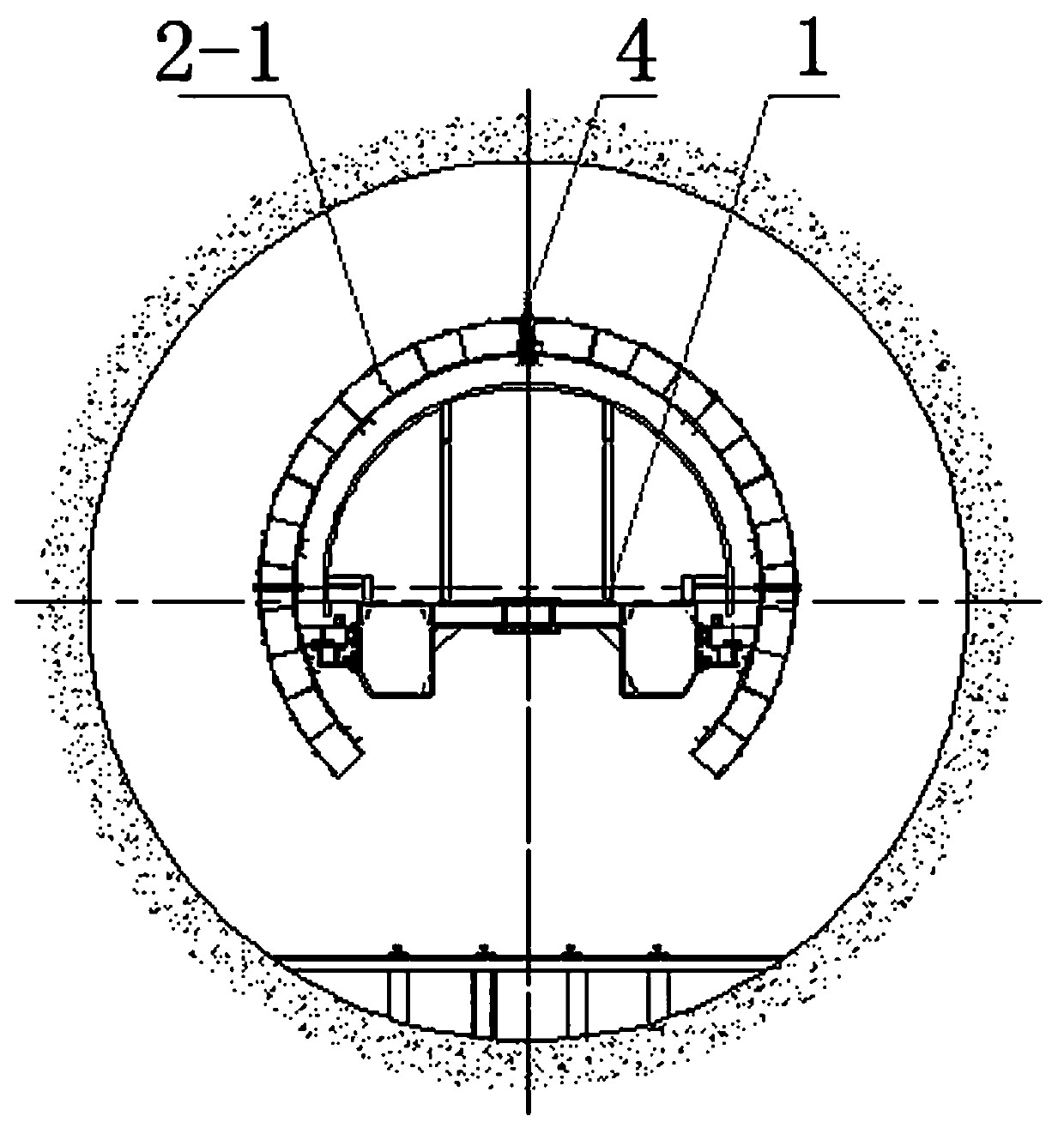

[0022] Embodiment 1, a kind of intelligent spraying system, such as figure 1 and image 3 As shown, it includes a gunite bridge 1 arranged along the axial direction of the tunnel. A rotary device is arranged in the circumferential direction of the gunite bridge 1. The rotary mechanism of the rotary device is connected with a spraying manipulator, and the spraying manipulator is provided with a spraying nozzle. 4. The slewing device can drive the spraying manipulator to rotate along the inner ring surface of the tunnel through the slewing mechanism. The spraying manipulator can expand and contract while rotating with the slewing device. The spraying nozzle 4 on the spraying manipulator can follow the action of the spraying manipulator. Convenient grouting on the inner ring surface of the tunnel.

[0023] The gunite bridge 1 is provided with a multi-degree-of-freedom three-dimensional scanner group connected to the measurement and control center, the rotary device, the gunite ...

Embodiment 2

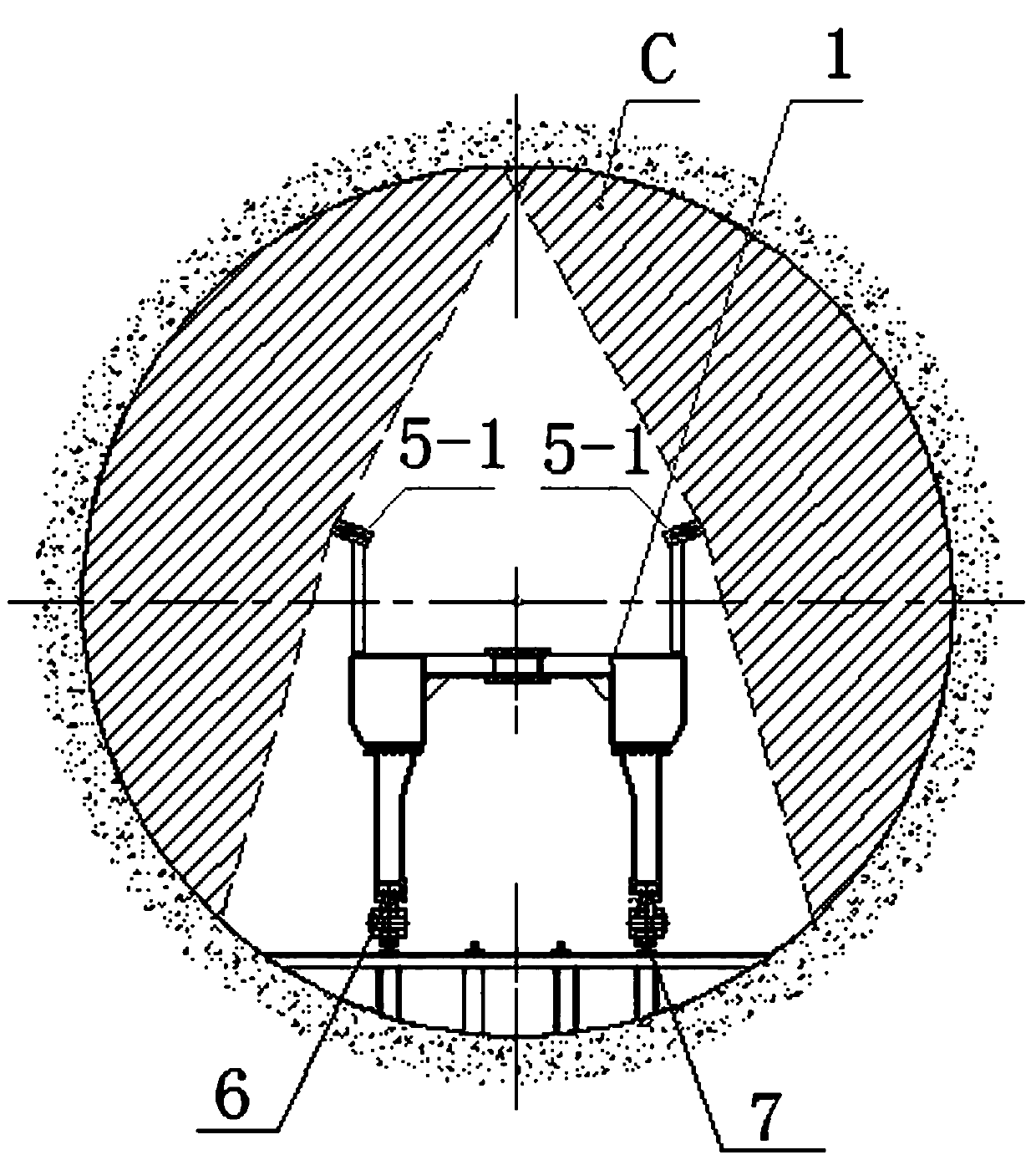

[0026] Embodiment 2, a kind of intelligent spraying system, such as figure 2 As shown, the point C in the figure is the scanning area. There are two first multi-degree-of-freedom three-dimensional scanners 5-1 and second multi-degree-of-freedom three-dimensional scanners 5-2, and the two first multi-degree-of-freedom three-dimensional scanners 5-1 are symmetrically arranged on the gunite bridge On the left and right sides of 1, two second multi-degree-of-freedom three-dimensional scanners 5-2 are symmetrically arranged on the left and right sides of the shotcrete bridge 1, which can not only effectively improve the scanning efficiency, but also ensure the integrity of the scanning area, avoiding the use of The problem of high cost caused by an overly complex multi-degree-of-freedom 3D scanner.

[0027] Other structures of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0028] Embodiment 3, a spraying support method of an intelligent spraying system, comprising the following steps:

[0029] Step 1: three-dimensional scanning, the measurement and control center controls the first multi-degree-of-freedom three-dimensional scanner 5-1 to scan the contour of the inner annulus of the tunnel, and returns the scanned image data to the measurement and control center;

[0030] Step 2: automatic first spraying, the measurement and control center automatically controls the first rotary device 2-1 to output a matching rotary speed according to the scanned image data in the first step, and automatically controls the first spraying manipulator 3-1 to drive the spray nozzle 4 Facing the matching injection direction, and then controlling the first rotary device 2-1 to drive the nozzle 4 on the first spraying manipulator 3-1 to spray the inner ring surface of the tunnel for the first time;

[0031] Step 3: Scanning detection, the measurement and control cente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com