Permanent magnet motor type low temperature liquid immersed pump structure

A low-temperature liquid and permanent magnet motor technology, which is applied in the direction of non-variable pumps, liquid fuel engines, and components of pumping devices for elastic fluids. It can solve the problem of reducing the output power of submersible pump motors, pump body filters, etc. Small filter area, large resistance and eddy current loss, etc., to avoid gasification loss, reduce gasification, and improve pump efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

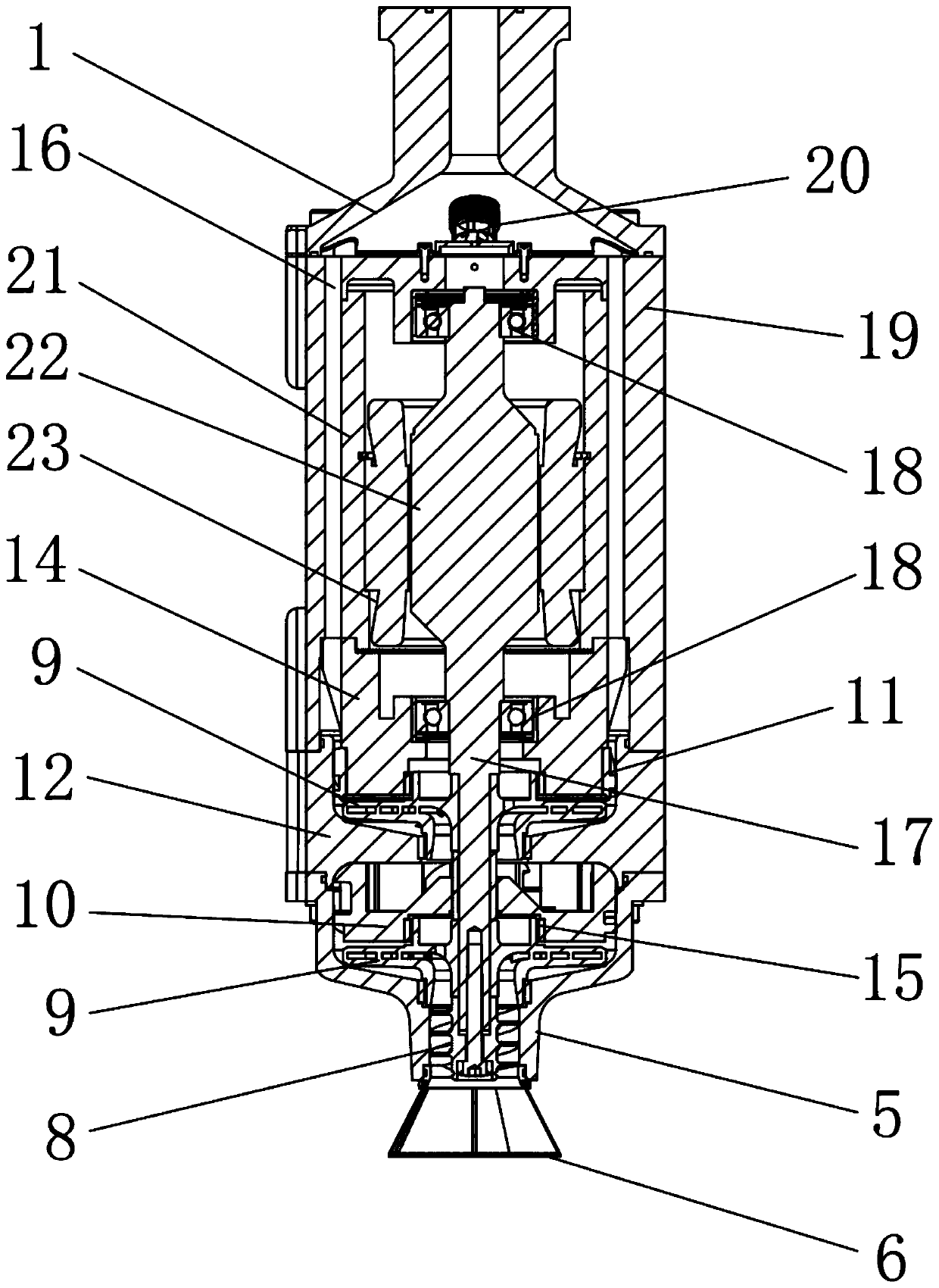

[0032] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

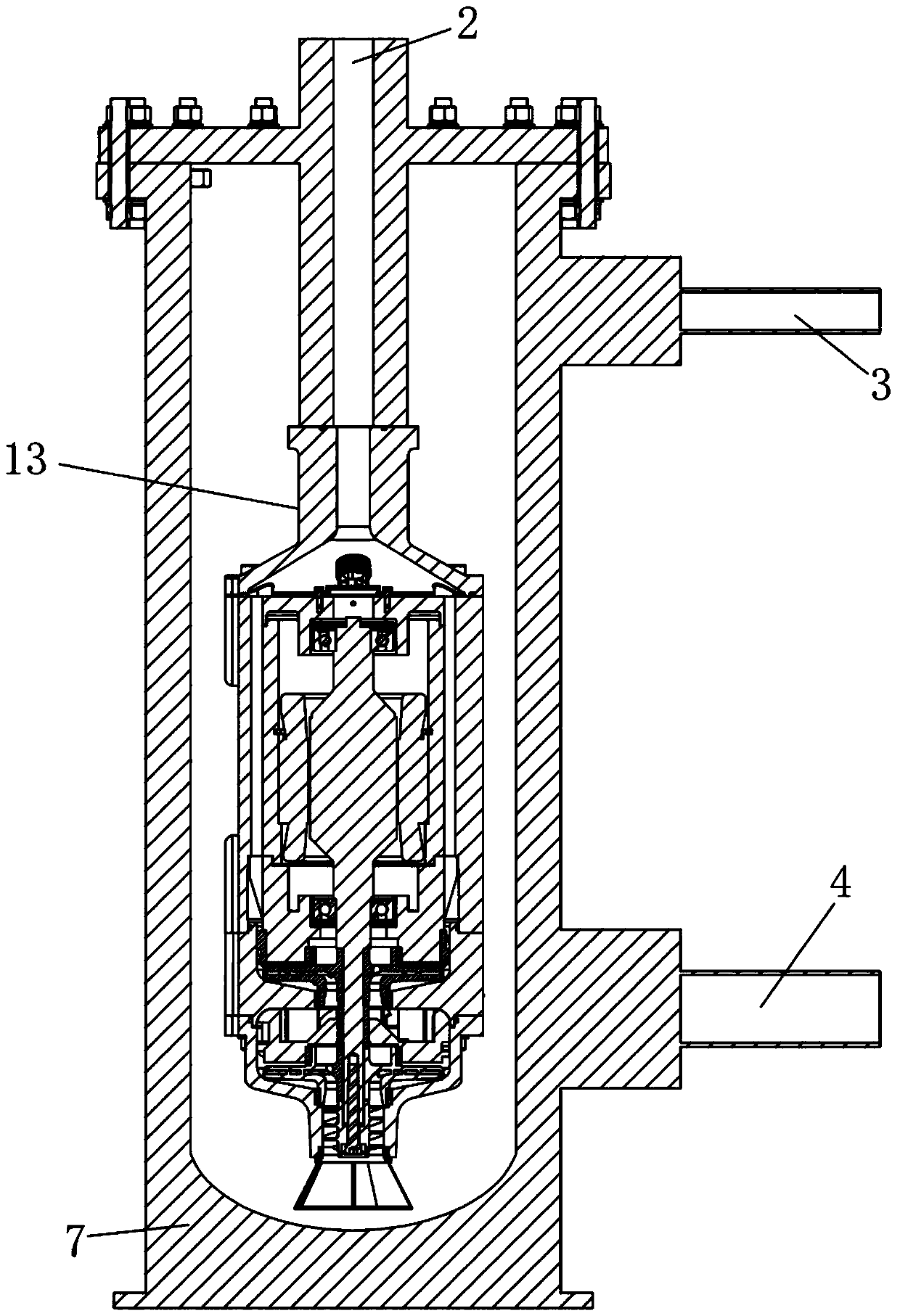

[0033] A permanent magnet motor type cryogenic liquid submersible pump structure, as shown in the figure, includes a pump casing (13), and the pump casing (13) includes a motor upper end cover (1), a motor casing (19), a secondary outer conductor casing (12), the first-stage outer guide casing (5); the bottom of the pump casing (13) is installed with a liquid filter body (6); the outer top of the motor casing (19) is fixedly provided with the motor upper end cover (1 ), the inner top is fixedly provided with a bearing seat, and the bottom end is fixedly provided with a second-level outer guide shell (12); Bearing sleeve (18) is provided;

[0034]The motor casing (19) is fixed with a motor sleeve (21); the top of the motor sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com