Leakage-proof device and installation method of construction pipeline interface

A technology of pipe joints and leak-proof devices, which is applied in the direction of pipe joints, pipe systems, pipes/pipe joints/fittings, etc., can solve problems such as troubles, and achieve the effects of convenient processing, avoiding losses, and saving installation time and effort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

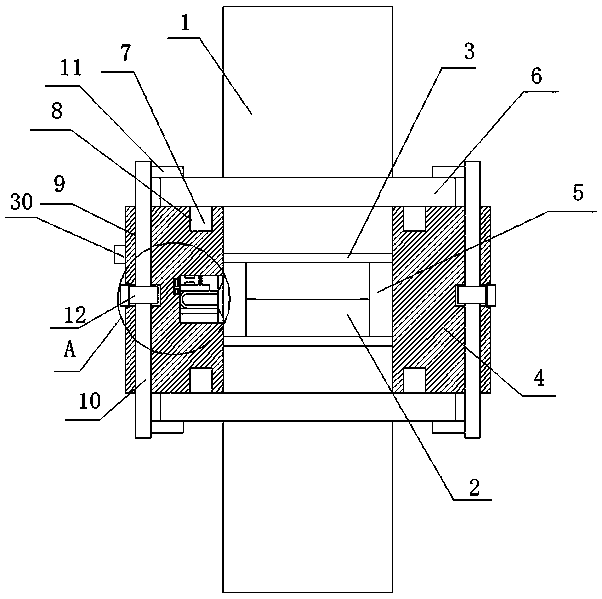

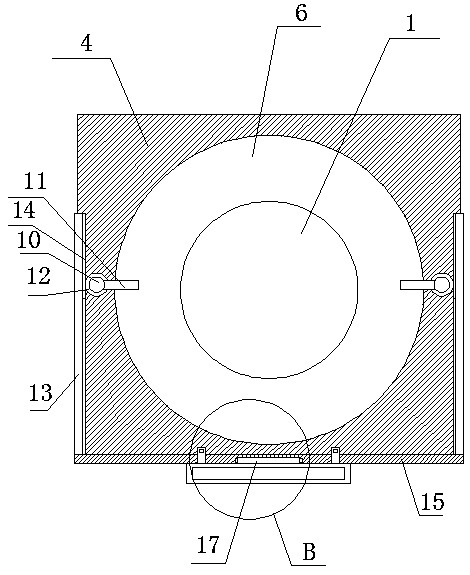

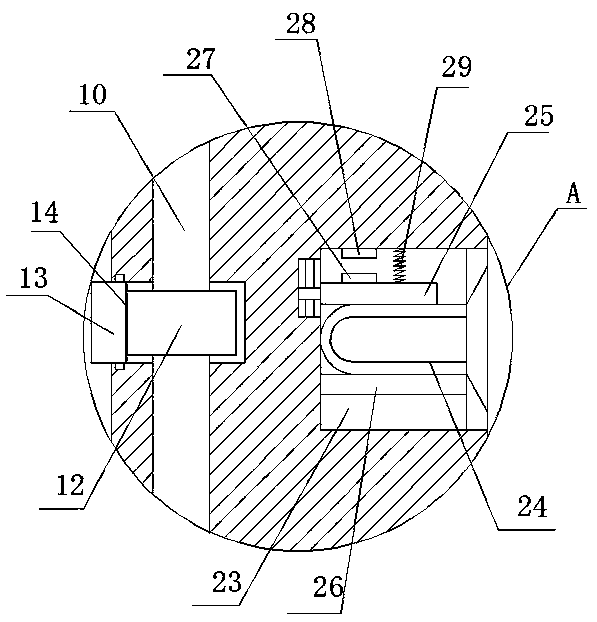

[0030] refer to Figure 1-6 , a leak-proof device for building pipe joints, comprising two pipes 1, one end of a joint 2 is fixedly installed on the sides of the two pipes 1 close to each other, the other ends of the two joints 2 are in contact, and the outer sides of the two pipes 1 The same connection seat 4 is installed, and a connection hole 5 is opened on the connection seat 4, and the two joints 2 are located in the connection hole 5, and the outer sides of the two joints 2 are fixedly provided with sealing rings 3, and the two sealing rings 3 are Sealed with the connection hole 5, the outer sides of the two pipes 1 are fixedly provided with an annular plate 6, and the sides of the two annular plates 6 that are close to each other are respectively in contact with the top and bottom of the connecting seat 4, and the connecting seat 4 is provided with a fixed Mechanism, the fixing mechanism cooperates with two annular plates 6.

[0031] In the present invention, the fixin...

Embodiment 2

[0044] refer to Figure 1-6 , a leak-proof device for building pipe joints, comprising two pipes 1, the sides of the two pipes 1 close to each other are fixed with one end of the joint 2 by welding, the other ends of the two joints 2 are in contact, and the two pipes 1 The same connecting seat 4 is installed on the outer side of the connecting seat 4, and a connecting hole 5 is opened on the connecting seat 4, and the two joints 2 are located in the connecting hole 5, and the outer sides of the two joints 2 are fixedly sleeved with a sealing ring 3, and the two sealing rings 3 are sealed with the connection hole 5, and the outer sides of the two pipes 1 are fixedly provided with an annular plate 6, and the sides of the two annular plates 6 that are close to each other are respectively in contact with the top and bottom of the connecting seat 4, and the connecting seat 4 is provided with There is a fixing mechanism, which cooperates with the two annular plates 6 .

[0045] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com