Wall thickness measurement tool of simple and cylindrical cabin casting

A cylindrical and cabin technology, applied in the field of wall thickness measuring tools for simple cylindrical cabin castings, can solve the problem of inability to measure the deep wall thickness of cylindrical cabin castings, no pits and protrusions, ultrasonic wall thickness measurement The instrument is not competent and other problems, to achieve the effect of convenient and quick reading, simple and easy to use structure, and improve detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

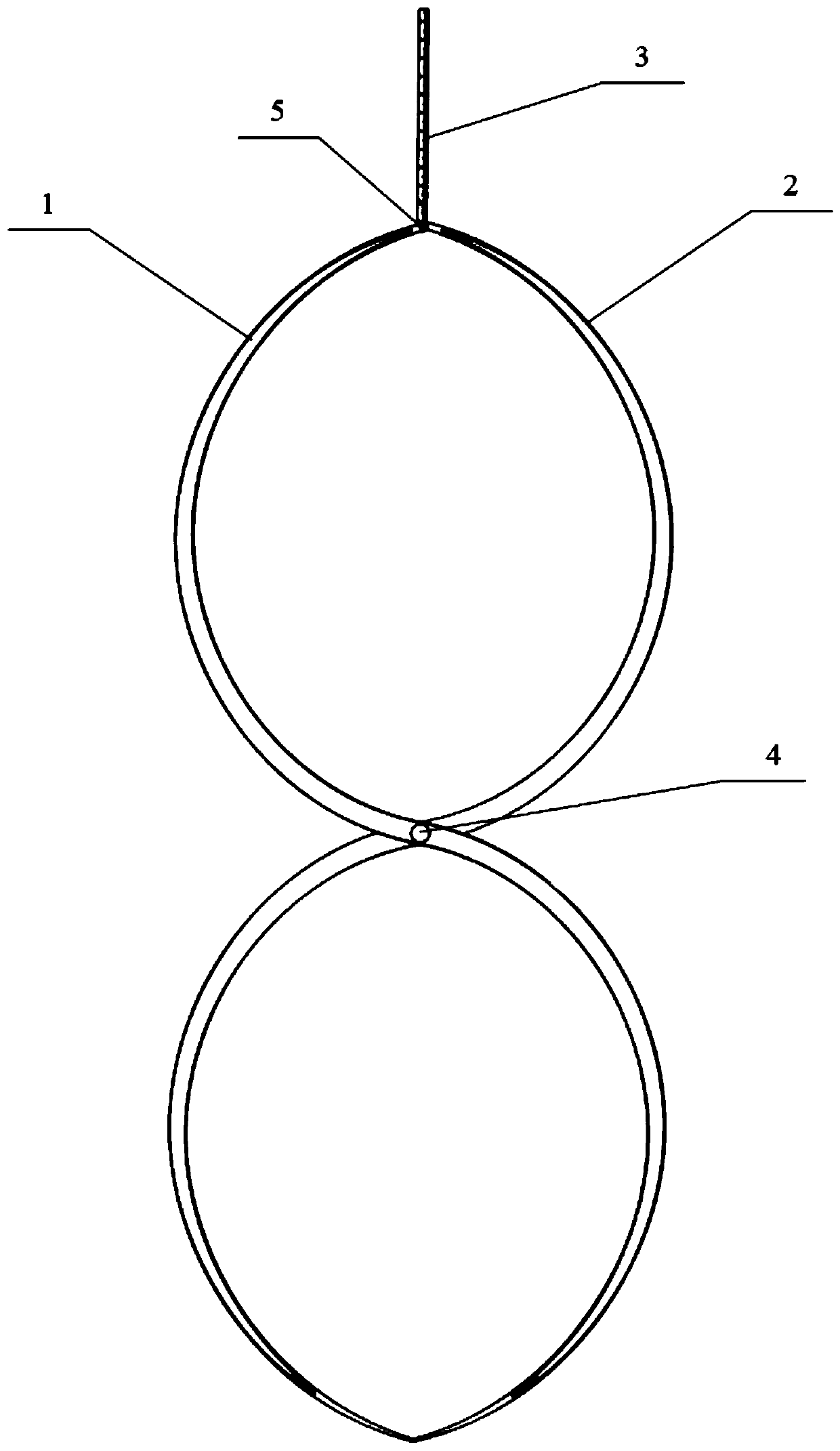

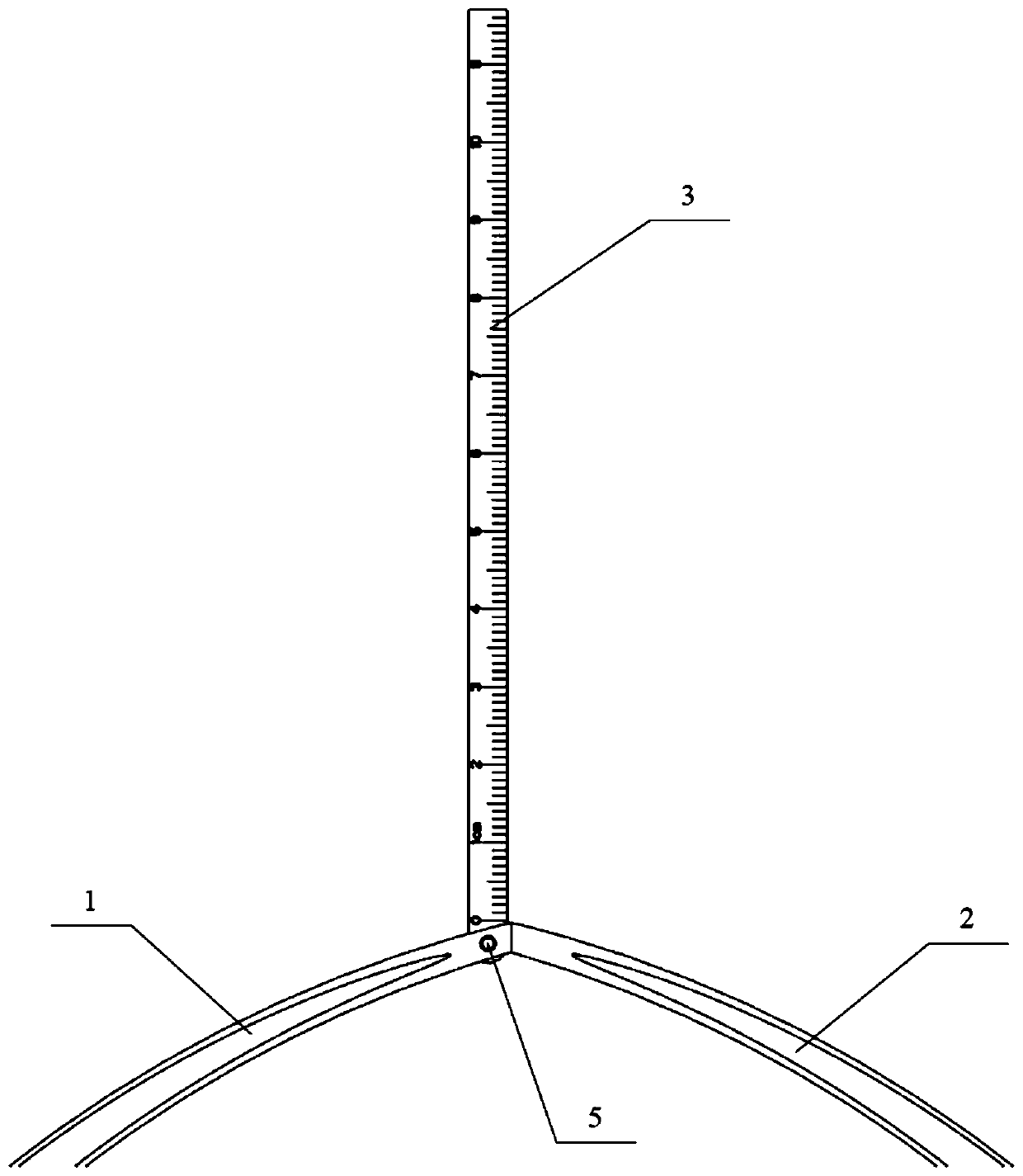

[0025] Measuring tools include: S-type stylus I, S-type stylus II, millimeter scale, rivet shaft, and rotating shaft.

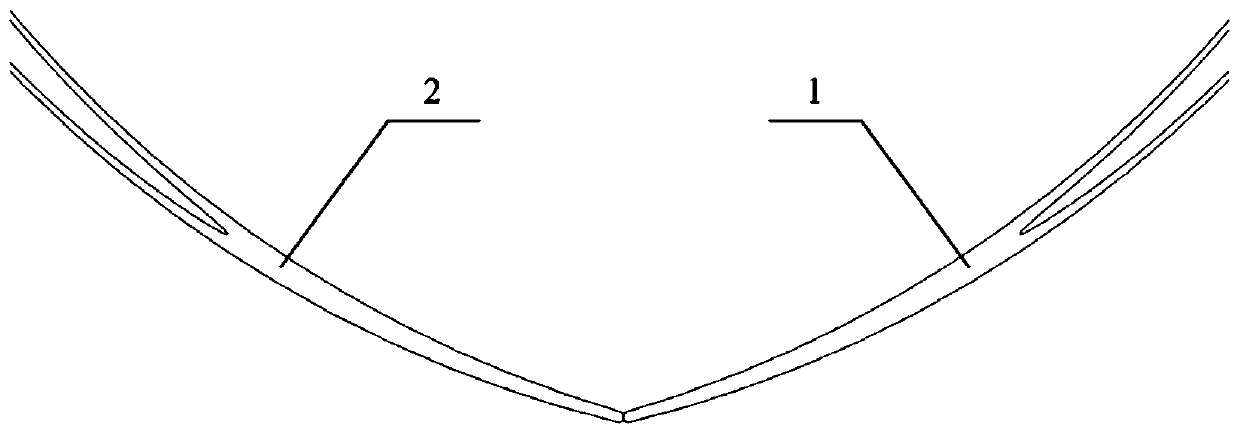

[0026] The S-shaped stylus I is an S-shaped flat steel structure (with a thickness of H), and there is a φ4-φ6mm through-hole at the center of the S-type, and the upper and lower parts are symmetrical about the center of the through-hole. The bottom end of the S-type stylus I is a ball head with a diameter of φ0.5~φ2mm. The top end is tapered and has a symmetrical through groove about the central plane inward from the end. The width of the through groove is smaller than the thickness of the millimeter scale. 0.08~0.15mm larger, and at the same time, there is a shaft installation hole along the thickness direction of the S-type stylus I on the groove. The hole diameter is 0.02-0.05mm smaller than the outer diameter of the shaft. The distance L of the end face (face A) is 3 to 5 mm. The uppermost side end surface (surface A) of the S-type stylus I passes throu...

Embodiment 2

[0034] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0035] A simple measuring tool for the wall thickness of cylindrical cabin castings, which solves the problem of measuring the wall thickness of cylindrical cabins with uneven surfaces in the casting state. The measuring tools include: S-type stylus I1, S-type stylus II2, millimeter scale 3 , rivet shaft 4, rotating shaft 5; S-type stylus I1 is an S-type 4mm thick flat steel structure, and there is a φ5mm through hole in the center of the S-type, and the upper and lower parts are symmetrical about the center of the through hole. The lowermost end of the S-type stylus I1 is a φ0.6mm ball head, the uppermost end is tapered and has a symmetrical through groove about the central plane inward from the end, the width of the through groove is larger than the thickness of the millimeter scale 3 At the same time, there is a shaft installation hole alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com