Automatic rod-connecting mechanism and grain heap rod-placing device

A rod mechanism and rod device technology, which is applied in the field of automatic rod receiving mechanism and grain pile lowering rod device, can solve the problems of high labor intensity, achieve the effects of reducing work intensity, improving work efficiency, and liberating labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

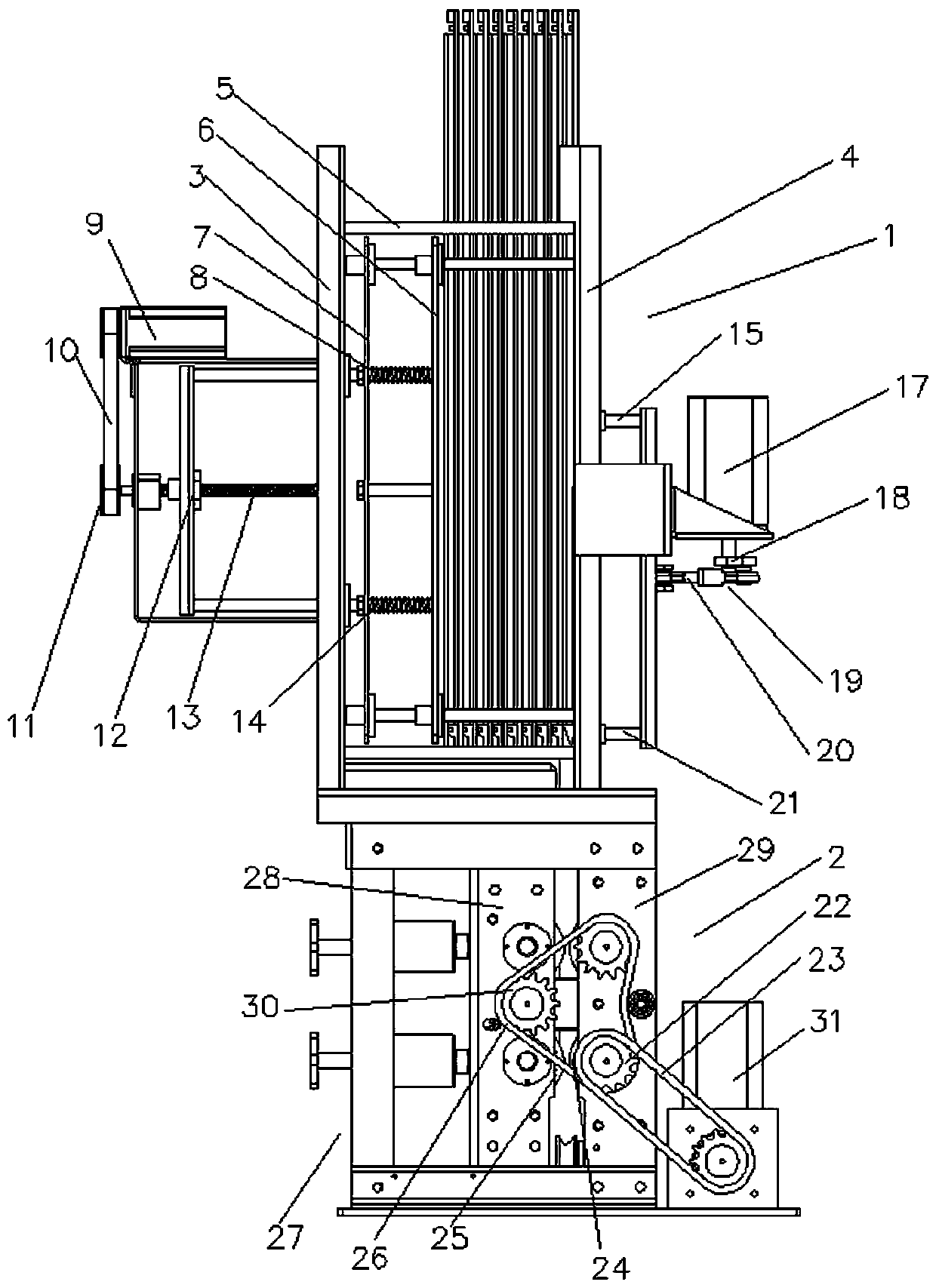

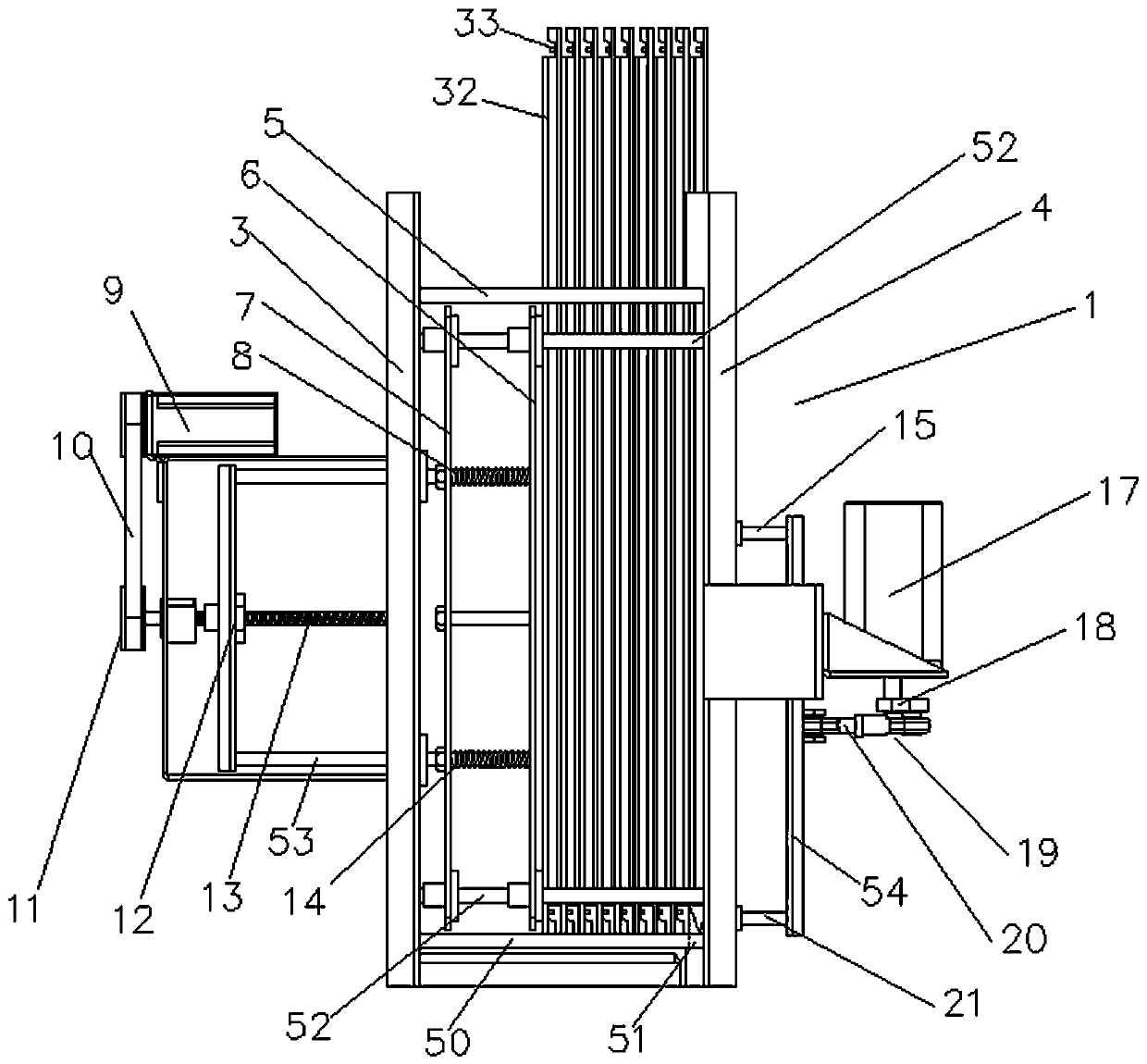

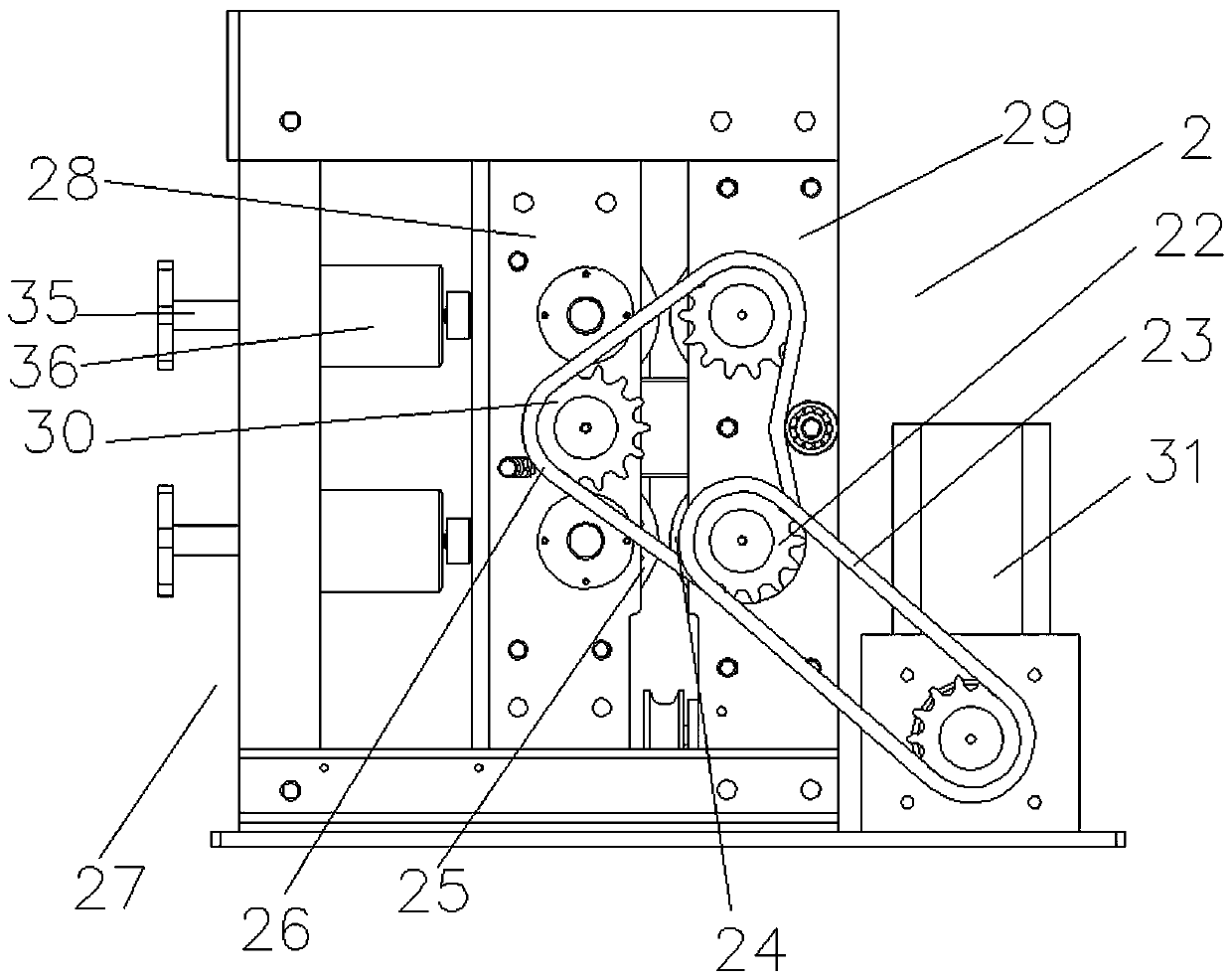

[0025] The embodiment of rod device for grain pile in the present invention is for example Figure 1~7 As shown: it includes an automatic rod connecting mechanism 1 arranged up and down, a lower rod mechanism 2 and a plurality of probe rods, and the automatic rod connecting mechanism 1 is detachably connected to the lower rod mechanism 2 through bolts. Down bar mechanism comprises device frame 27, and device frame comprises device frame main body 27, is fixed on the fixed support 29 on the device frame main body and guides and moves along the left and right directions and is assembled on the mobile support 28 on the device frame main body, and mobile support 28 is positioned at fixed support 29 On the left side of the left side, the fixed bracket is rotatably equipped with two up and down rotation axes arranged up and down along the right side lower rod roller 24 extending along the front and rear direction, and the moving bracket is rotatably equipped with two up and down rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com