Earpiece plate clamping and heating mechanism

A technology of heating mechanism and glasses feet, which is applied to the field of heating mechanism for holding glasses foot plates, and can solve problems such as difficult operation, pin offset, deformation of glasses foot plates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

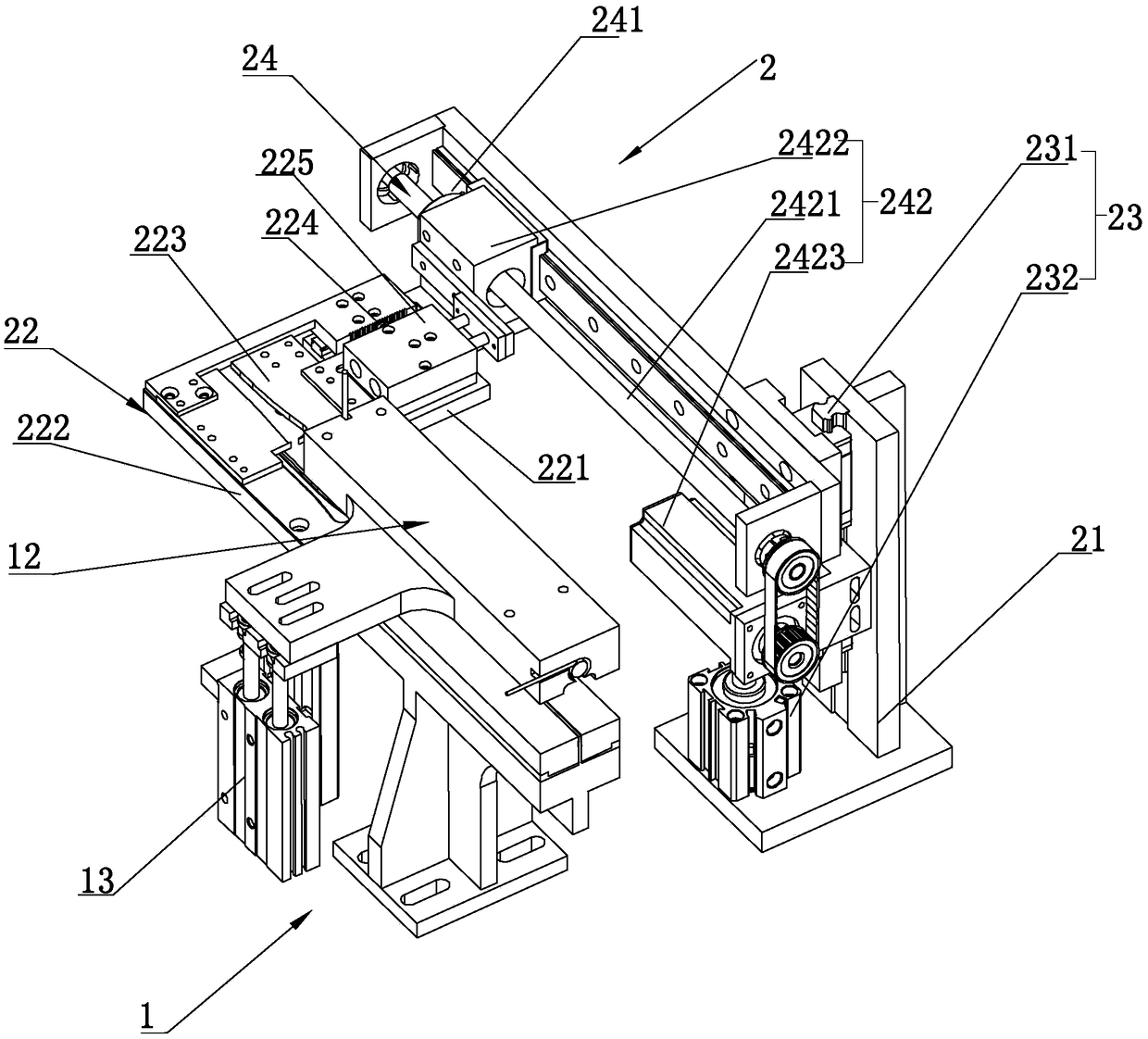

[0026] Refer to the attached Figure 1 to Figure 5 The embodiment of the clamping and heating mechanism for the glasses leg plate of the present invention will be further described in detail.

[0027] A clamping and heating mechanism for an eyeglass plate, comprising a heating device 1 for heating the eyeglass plate and a clamping device 2 for taking the eyeglass plate from the heating device 1 and moving it to a mold. The clamping device 2 is placed on the mold. One side of the heating device 1; the clamping device 2 includes a frame 21 and a manipulator 22 for clamping the glasses leg plate, and an upper and lower drive assembly 23 that drives the manipulator 22 to move up and down is set on the frame 21 and drives the manipulator 22 to move back and forth The front and rear drive assemblies 24.

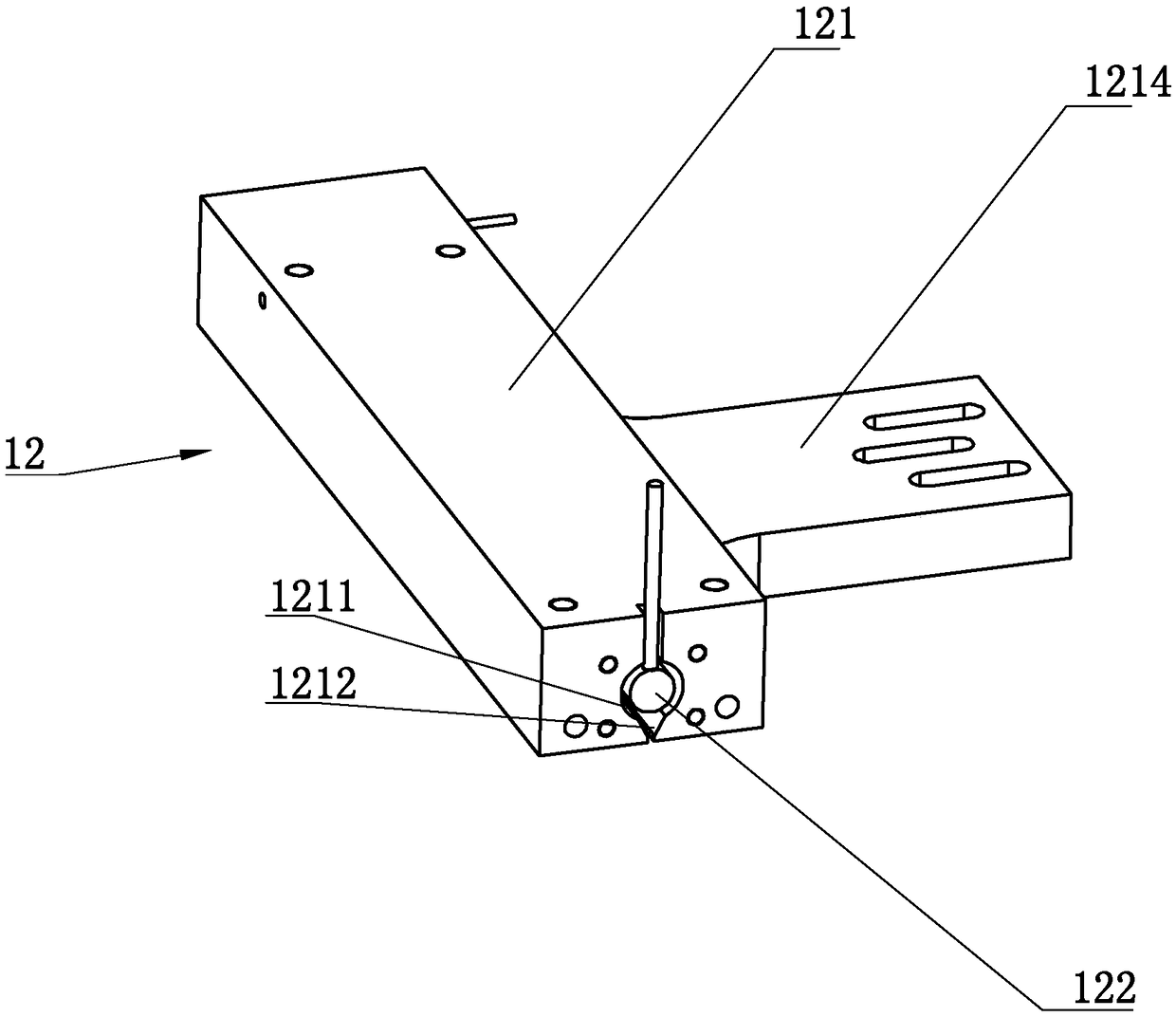

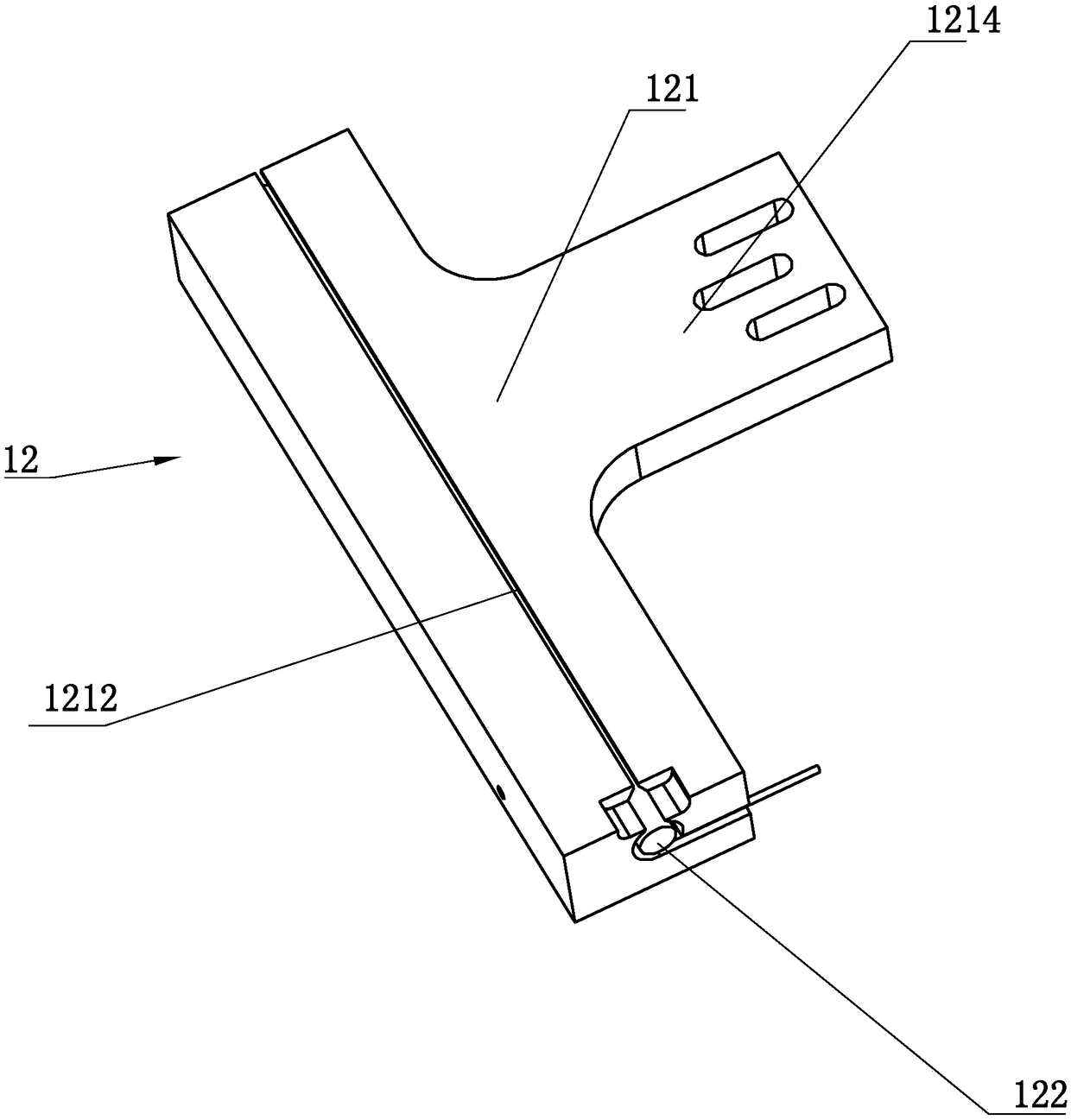

[0028] The heating device 1 includes a heating table 11, a heater 12 placed above the heating table 11, and a heating driver 13 that drives the heater 12 to move up and down; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com