A modified conductive paste and its preparation method and application

A conductive paste and modification technology, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve the problem of low conductivity of carbon-based conductive paste and poor conductivity of carbon-based conductive paste. and other problems, to achieve the effect of low cost, high thermal conductivity and high electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

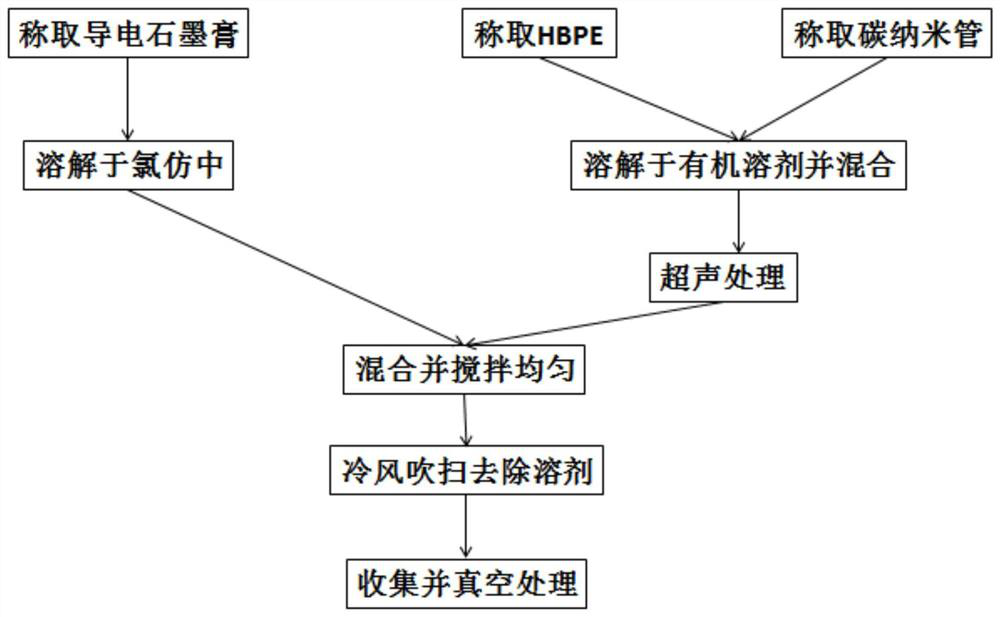

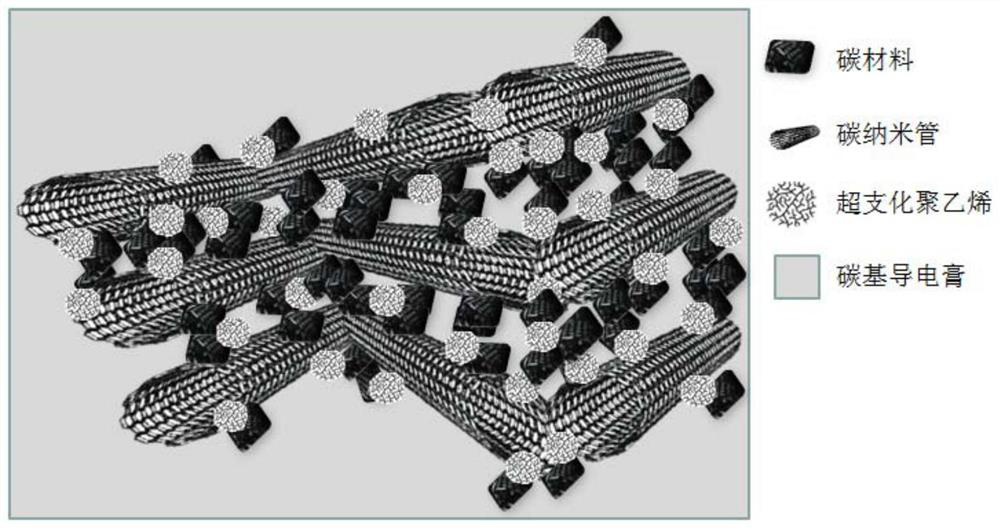

[0052] The embodiment of the present application also provides a method for preparing the above-mentioned modified conductive paste, which includes the following steps:

[0053] Step 1. Mixing the carbon-based conductive paste and an organic solvent to form a carbon-based conductive paste solvent, that is, the first solution.

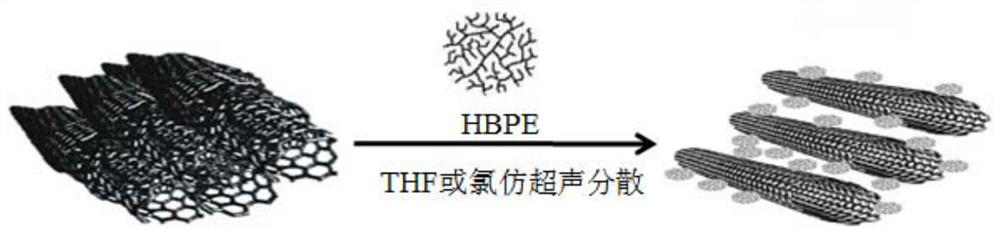

[0054] Mix carbon nanotubes, hyperbranched polyethylene and an organic solvent to disperse carbon nanotubes evenly to form a carbon nanotube / hyperbranched polyethylene mixed solution, that is, the second solution. Usually, carbon nanotubes, hyperbranched polyethylene In the initial mixed solution formed by uniform mixing of ethylene and organic solvent, the concentration of carbon nanotubes is 0.5-500 mg / mL, and the mass ratio of hyperbranched polyethylene to carbon nanotubes is 0.005-10:1.

[0055] In this embodiment, the organic solvent includes at least one selected from the group consisting of chloroform, tetrahydrofuran, petroleum ether and diethyl...

Embodiment 4

[0108] The difference of embodiment 4-10 is that the kind of added carbon nanotube is different, what embodiment 4 adopts is common single-walled carbon nanotube SWCNT, and what embodiment 5-7 adopts respectively is double-walled carbon nanotube DWCNT , multi-walled carbon nanotube MWCNT, highly conductive multi-walled carbon nanotube HEMWCNT, what embodiment 8-10 adopted is the multi-walled carbon nanotube MWCNT that is connected with functional group. Among them, the price of single-walled carbon nanotubes SWCNT is the most expensive, and the modification effect is better. Double-walled carbon nanotubes DWCNT and multi-walled carbon nanotubes MWCNT can be well combined with carbon-based conductive paste with the help of hyperbranched polyethylene HBPE. Compatibility, can greatly improve the conductivity of carbon-based conductive paste; compared with the above-mentioned carbon nanotubes, HEMWCNT, a highly conductive multi-walled carbon nanotube, can be greatly improved with a...

Embodiment 1

[0123] The difference between embodiment 1 and embodiment 11 is that the amount of added carbon nanotubes is different, Figure 4 The left figure in is the LED bulb luminance figure of the modified conductive paste of embodiment 1, Figure 4 The right figure in the middle is the LED bulb luminance figure of the modified conductive paste of embodiment 11. Such as Figure 4 As shown, the part of the black ball and connected with the wire is a modified conductive paste, which can be molded into various shapes at room temperature. The LED bulb uses a series circuit, so in Figure 4 The part circled in the middle is the brightness of the bulb in the normal circuit, and the dark part is the brightness of the bulb corresponding to the modified conductive paste; comparing the brightness of the LED bulb in the left and right pictures, it can be clearly observed Figure 4 The brightness of the LED bulb in the middle right picture is higher, that is, as the content of carbon nanotubes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com