Safety high-low voltage distribution cabinet

A high and low voltage, power distribution cabinet technology, applied in substation/power distribution device housing, electrical components, substation/switch layout details, etc., can solve problems such as unfavorable maintenance, damage to power distribution modules, poor light, etc., to achieve good Inspection light, inspection safety, uniform heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

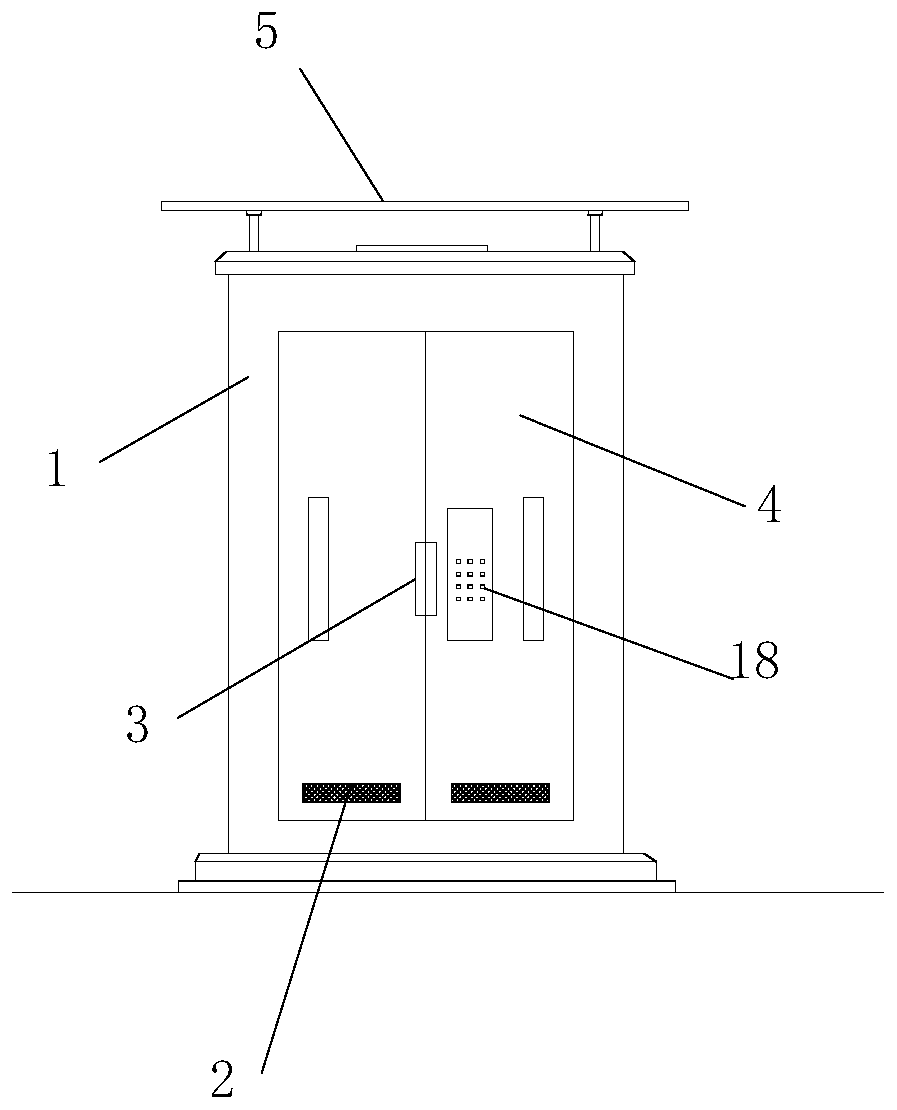

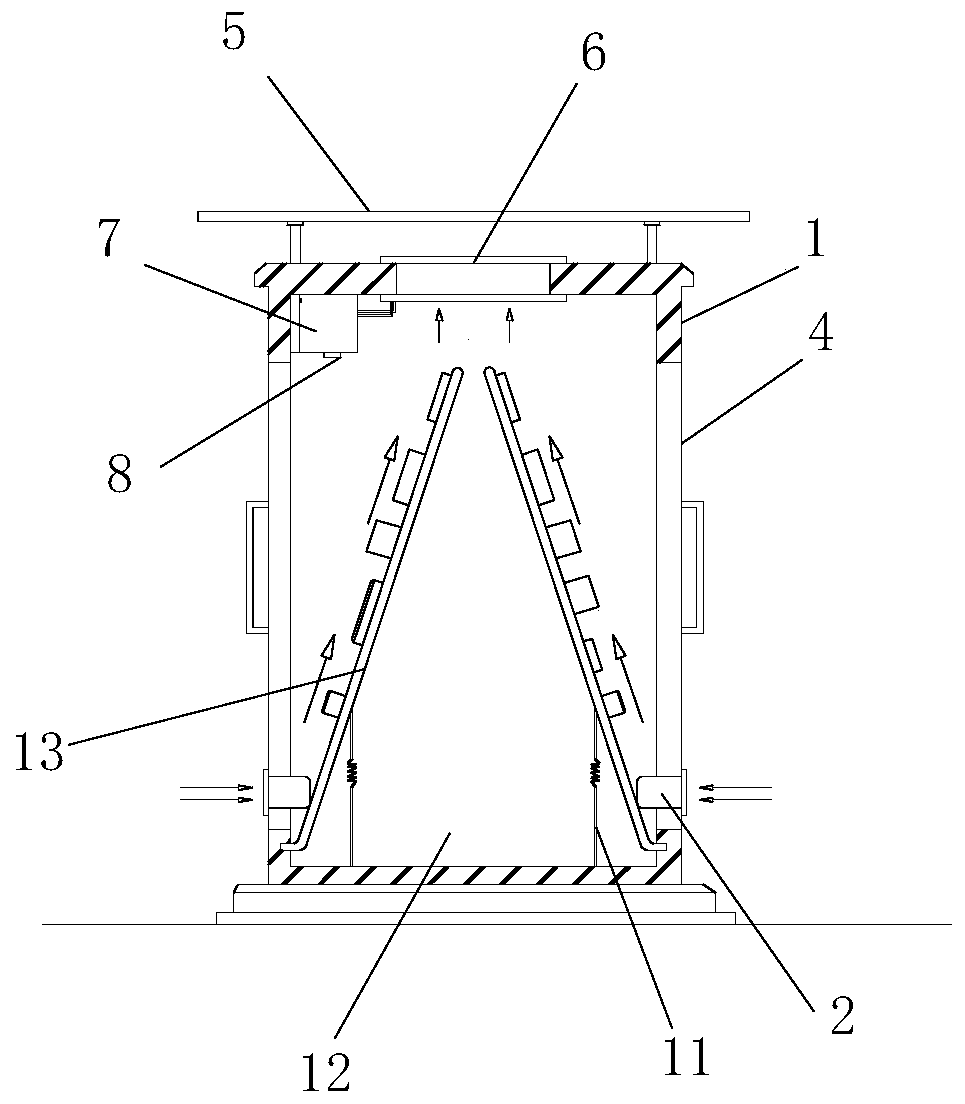

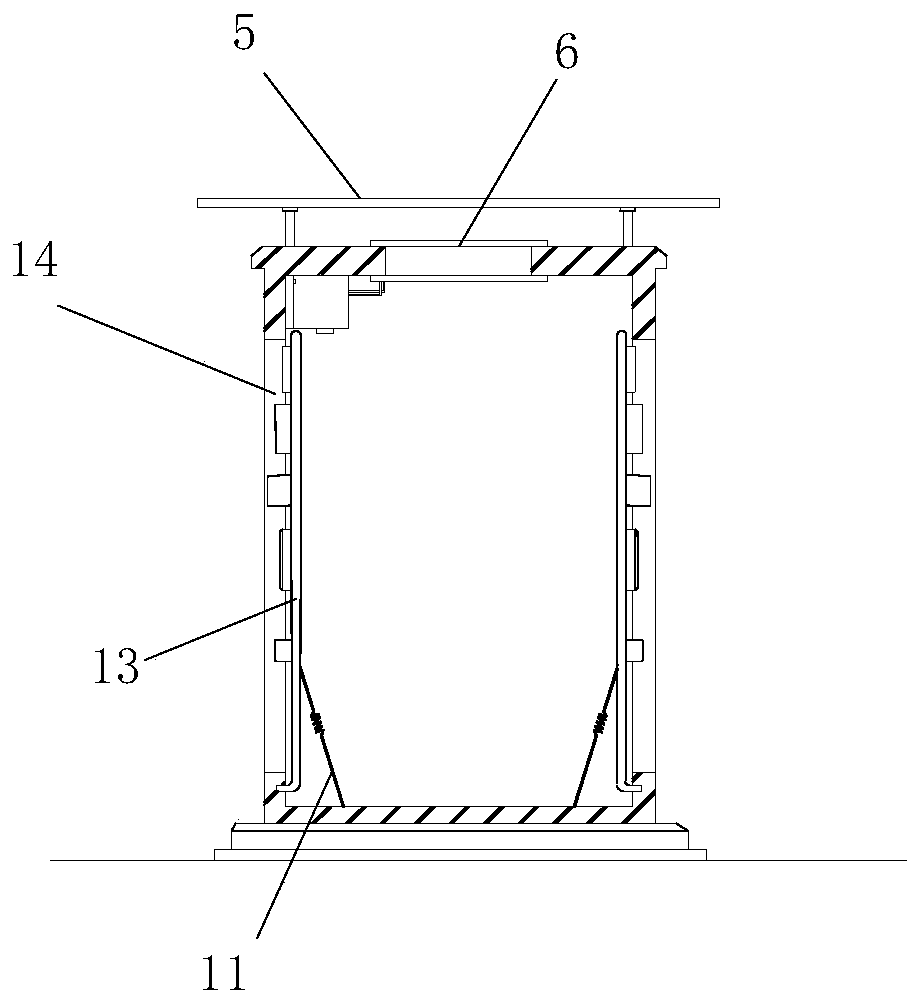

[0023] Such as figure 1 As shown, the safety type high and low voltage power distribution cabinet includes a cabinet body 1. There is an installation cavity 12 inside the cabinet body 1. A door body installation cavity 14 is respectively opened on both sides of the cabinet body 1. Inside the door body installation cavity 14 are Install two door panels 4, one end of the door panel 4 is hinged with the cabinet body 1, and the other side of the door panel 4 is fixed by mutual attraction through the electromagnetic lock 3;

[0024] Inside the cabinet body 1, an elastic mounting plate 13 is arranged vertically close to the door panel. The bottom side of the elastic mounting plate 13 is bent and fixed on the inner wall of the installation cavity of the cabinet body 1. The inner surface of the door panel 4 protrudes near the root of the elastic mounting plate. A dust-proof device 2 is provided. When the two door panels 4 on adjacent sides are sucked together, the inwardly convex dust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com