Devices and methods for manufacturing hairpin winding

A hairpin and winding technology, applied in the manufacture of motor generators, prefabricated windings embedded in motors, electromechanical devices, etc., can solve problems such as insulation difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

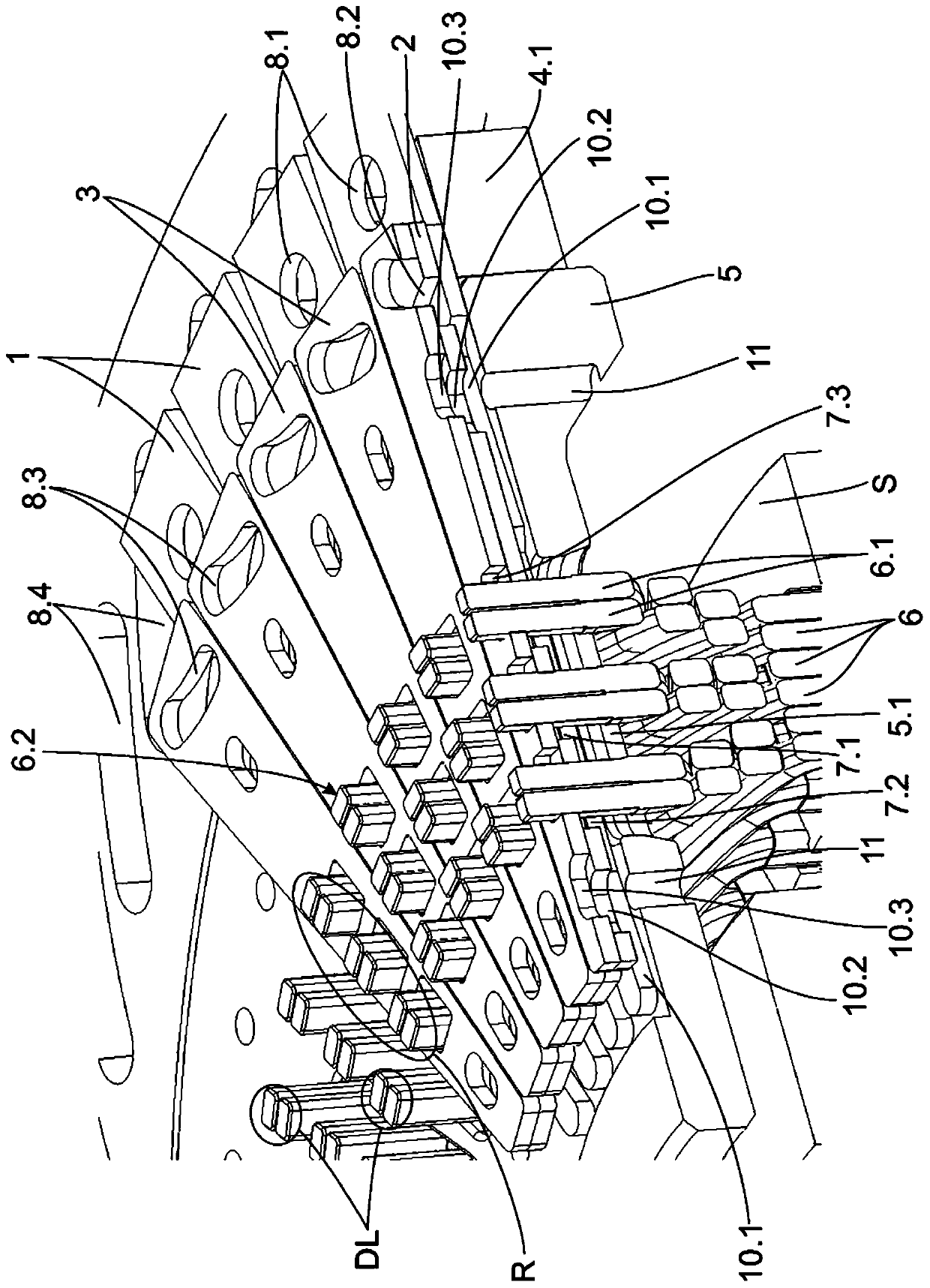

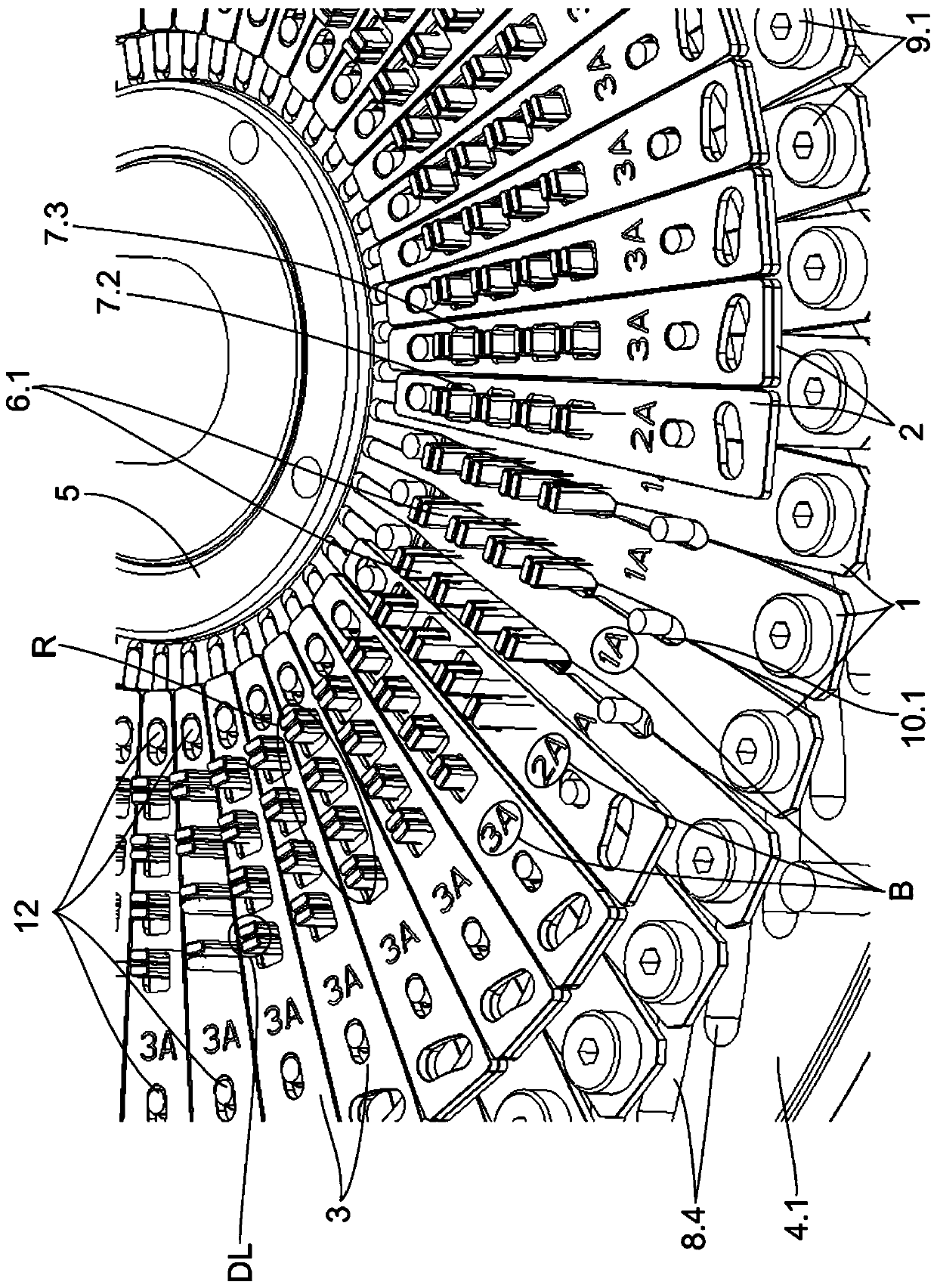

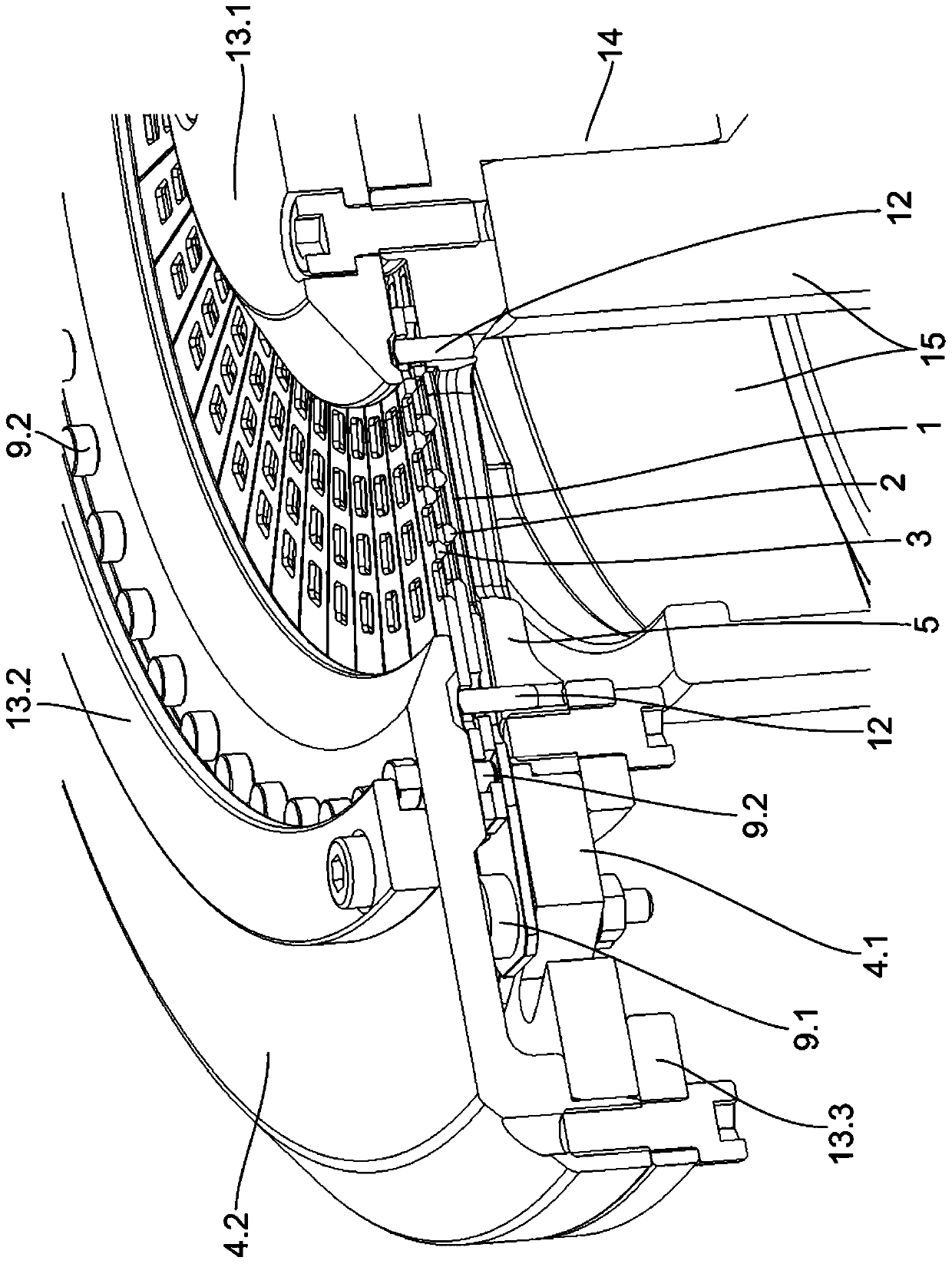

[0036] figure 1 A part of an element according to an embodiment of the invention during application is shown, ie a device with a contact end 6.1 of a hairpin 6 placed to a winding of an electric machine (here a stator S). For better illustration, not all parts of the device are shown.

[0037] The device has a plurality of first orientation elements 1 which are wedge-shaped and are arranged in each case between the arrangement R formed by the contact ends 6.1. A first plane is formed by the first alignment elements 1 arranged next to each other in the circumferential direction, which in the embodiment shown lies on the support plate 5 . Between the first orientation elements 1 there is provided an opening 7.1, which is located along the side facing the contact end 6.1. In the example shown, the opening 7 . 1 is formed by a wedge-shaped taper between the two first alignment elements 1 . By moving the first alignment elements 1 in the radial direction towards the center, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com