Gripping arm for containers and gripping device comprising such a gripping arm

A technology for grabbing arms and containers, which is applied in the field of grabbing arms to achieve the effect of reducing the probability of maintenance and repair and producing fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

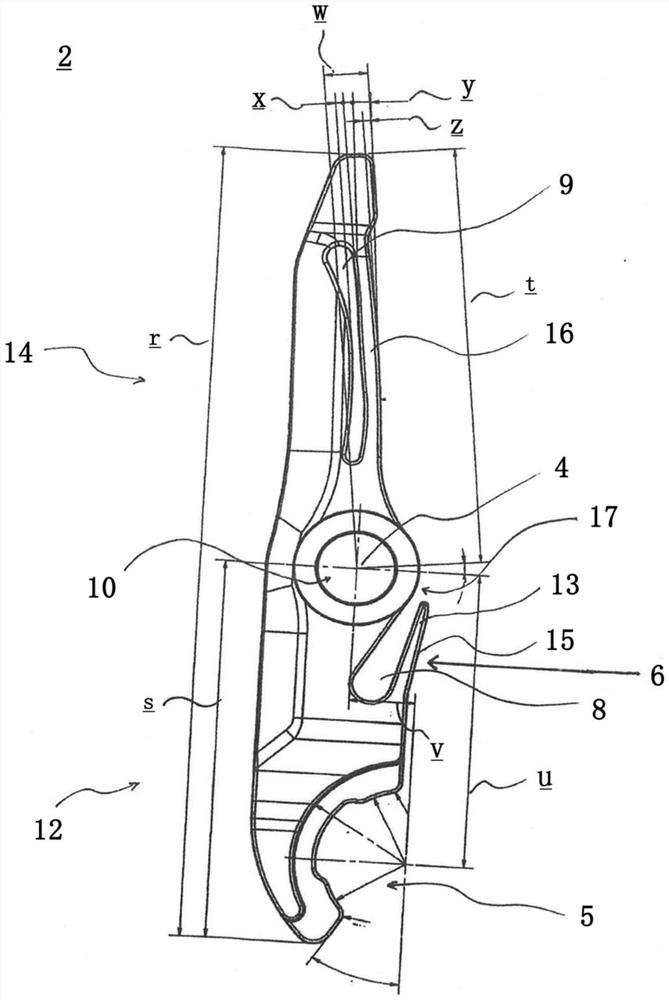

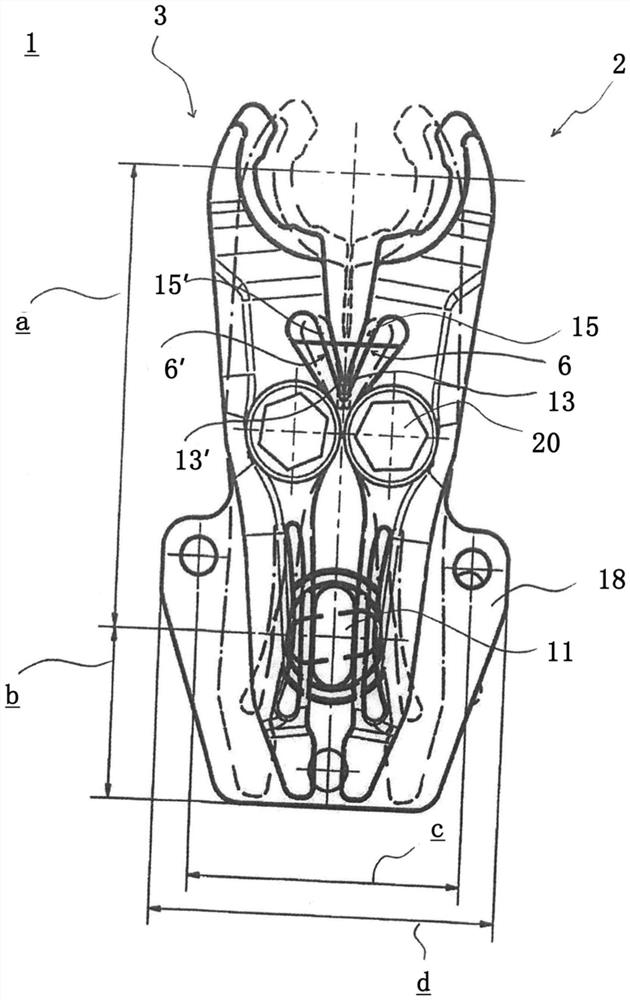

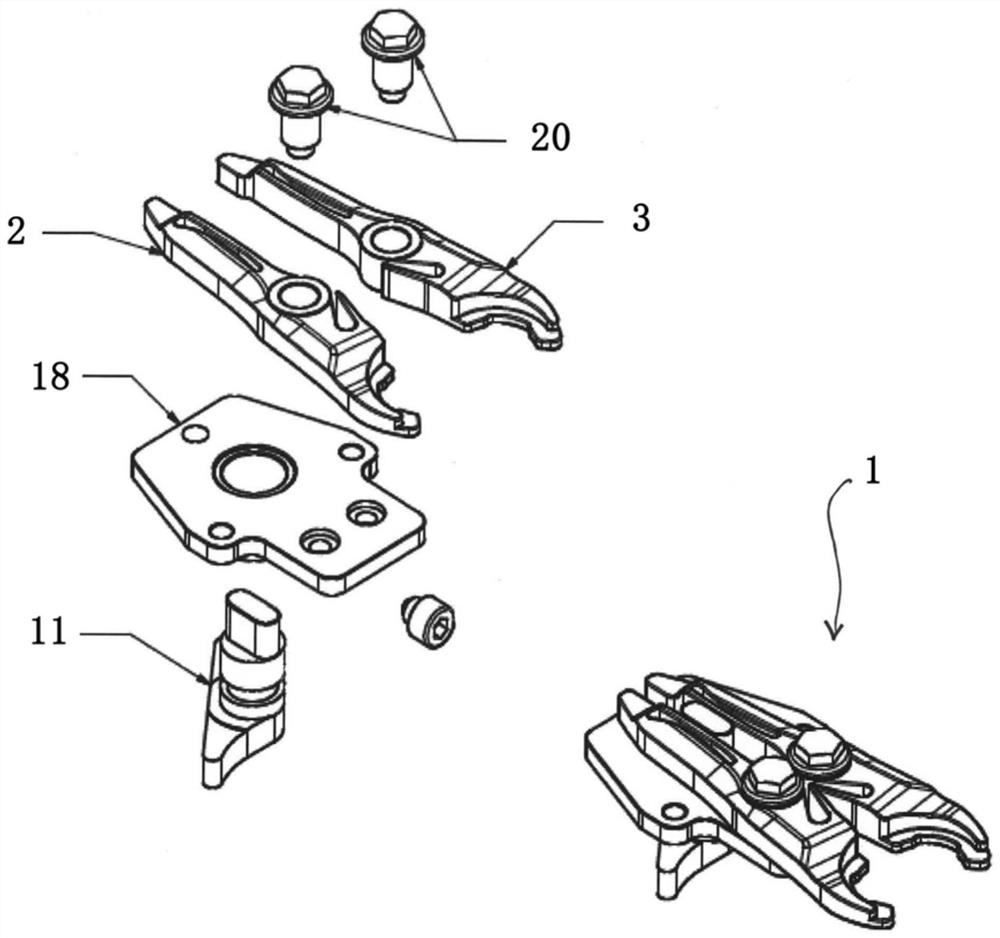

[0031] exist figure 1 In the perspective view of , a grabbing arm 2 according to the present disclosure is shown.

[0032] The gripper arm 2 is preferably elongate and is divided into a front section 12 and an end section 14 . A gripping arm 2 is provided for a device for gripping, holding and guiding, in particular bottle-shaped containers, which has a rotatably mounted control cam, not shown here, to move the gripping section of the gripping arm 2 5Move from open position to grab position. Between the two sections 12 and 14 there is a bore 10 for supporting a bearing pin (not shown here) for pivotally fixing the gripper arm 2 in the device, or the bore is located in both sections the junction between. A spring tongue 6 is formed in the front end section 12 , which serves as an opening device for moving the pick-up section 5 of the pick-up arm 2 from the pick-up position into the open position. Between the spring tongue 6 and the gripper arm 2 , in particular the front en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com