Pre-pour slump maximization of delivered concrete

一种混凝土、坍落度的技术,应用在黏土制备装置、化学仪器和方法、控制装置等方向,能够解决夸大量、图表误解、不正确等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

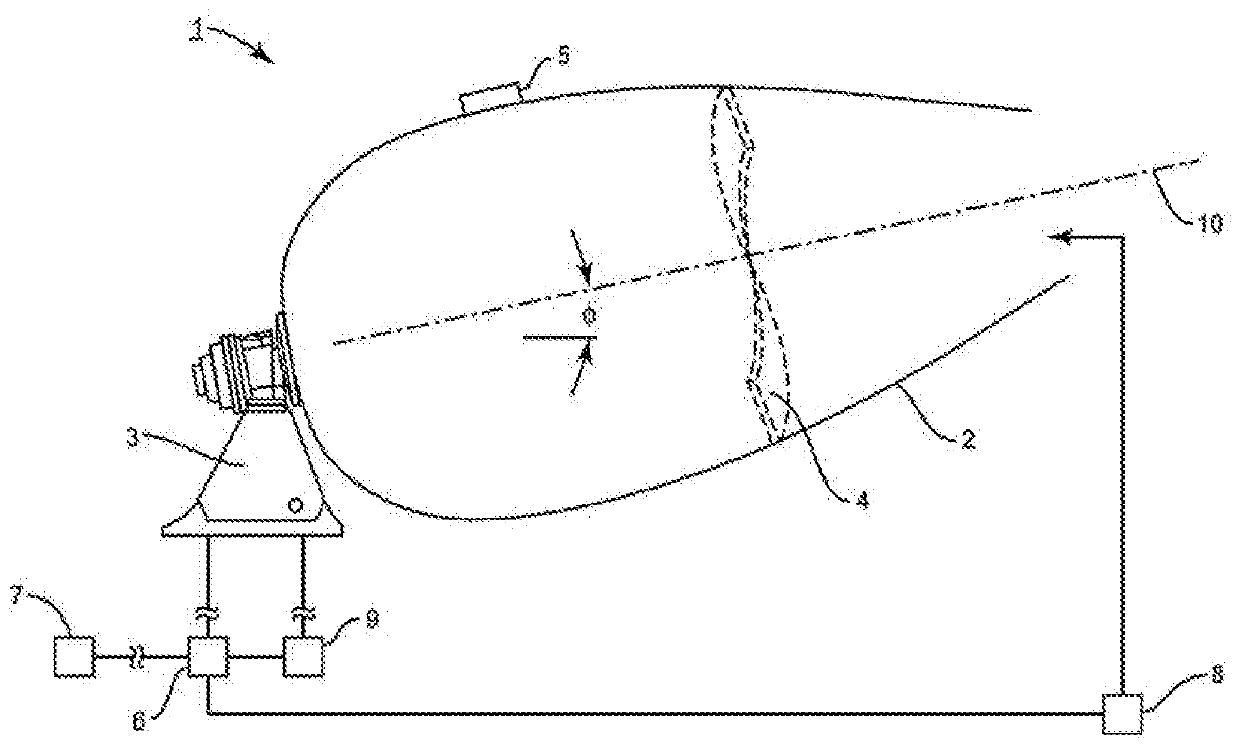

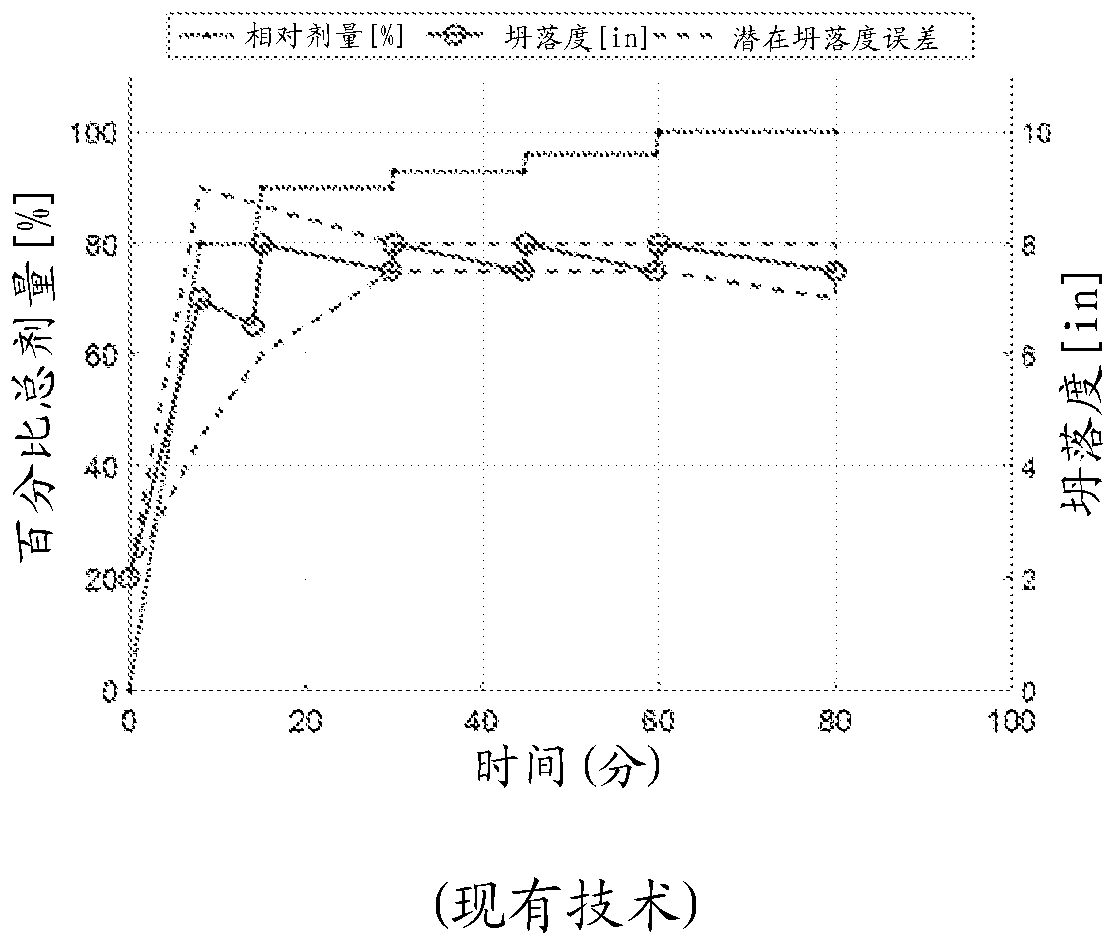

[0077] The next thing is an example that demonstrates the unexpected benefits and delay of most percentage addition of chemical admixtures during shipping delivery. Sixteen loads of concrete based on the same concrete mix design were batched and delivered in the same concrete mixer truck equipped with an automated slump management system (Verifi LLC of Cambridge, Massachusetts USA). All concrete loads were initially adjusted to a slump of 2 inches (±1) without the use of cement dispersant chemical admixtures. At this point, take a first sample to determine strength before adding blends and to ensure consistent water content is achieved. The mixing speed of the mixer drum was set at three (3) revolutions per minute (rpm) for sixty (60) minutes.

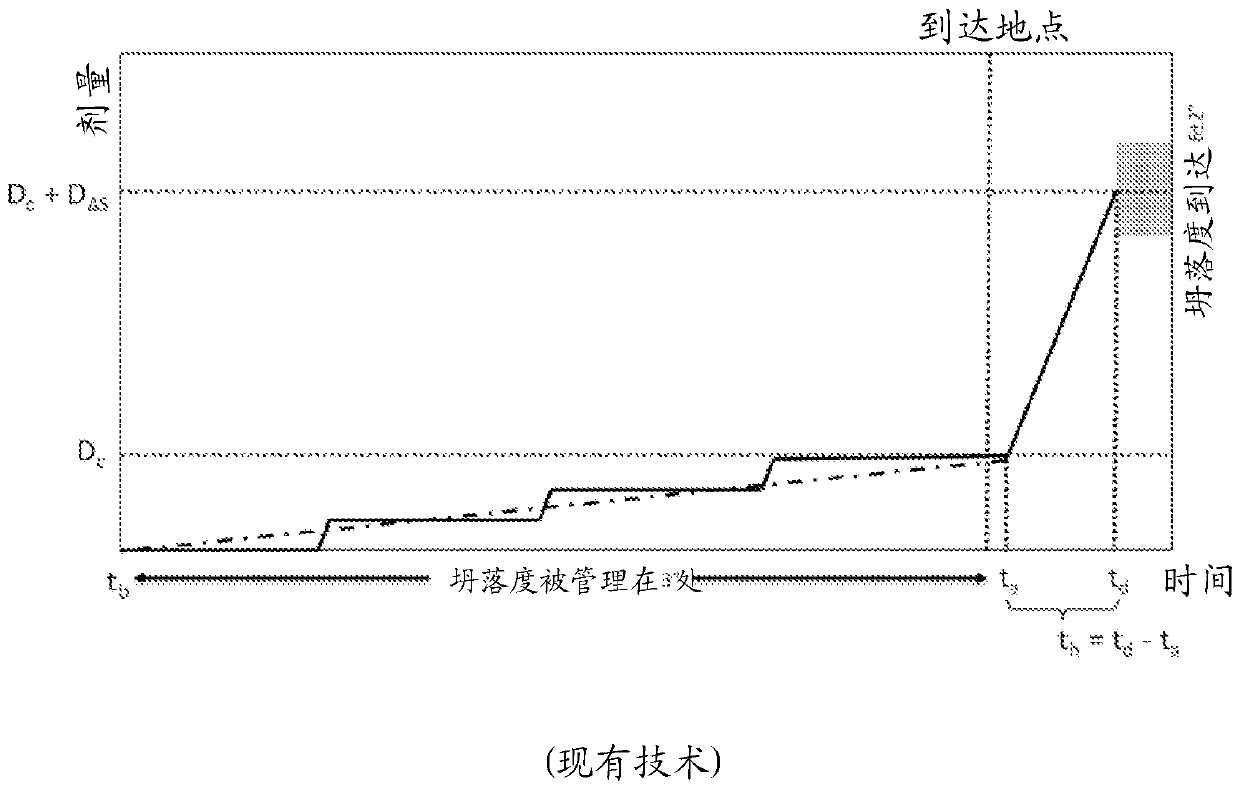

[0078] Scenario 1 was used on ten loads where concrete was dosed with chemical admixtures to achieve an 8 inch slump immediately after initial slump was confirmed with an automated slump management system. The slump was maintained at...

example 2

[0084] In addition to dose-response, comparisons between strengths before admixture addition and at the end of each regimen were analyzed. Any variation in strength will be due to different mixing schemes, since the water and air contents are nominally equal. The increase in strength as a percentage of the initial strength of the concrete (before adding chemical admixtures) was calculated as follows: (Ultimate Strength - Initial Strength) / Initial Strength.

[0085] For regimen 1, a mean increase of 0.6±0.1% was observed, while for regimen 2, a mean increase of 5.2±0.1% was observed. ANOVA shows that the means of the sets are statistically different at 5% significance. Plus / minus values indicate variance around the mean.

example 3

[0087] Further testing was done on 28 strength attributes of concrete, as tested on the concrete mix prior to adding chemical admixtures, for additional confirmation that the water content was similar for all mixes. Results from ANOVA showed no statistically significant difference between the means of the two data sets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump flow | aaaaa | aaaaa |

| slump flow | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com