Heating cooker

A technology for cookers and heating parts, applied to electric heating fuel, lighting and heating equipment, electric/magnetic/electromagnetic heating, etc. It can solve the problems of low speed, heavy structure, and the inability of reverse rotation of shaded pole motors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

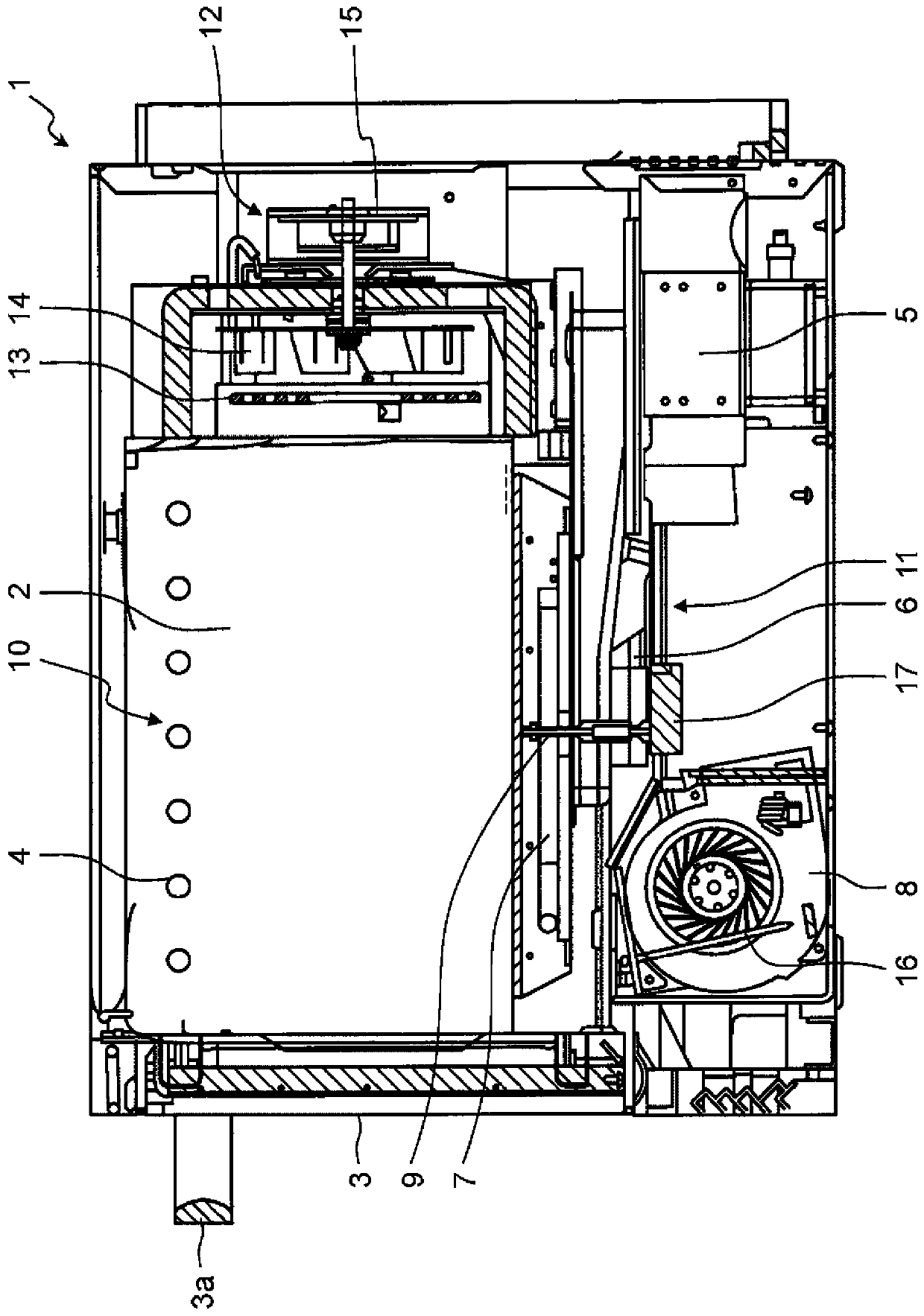

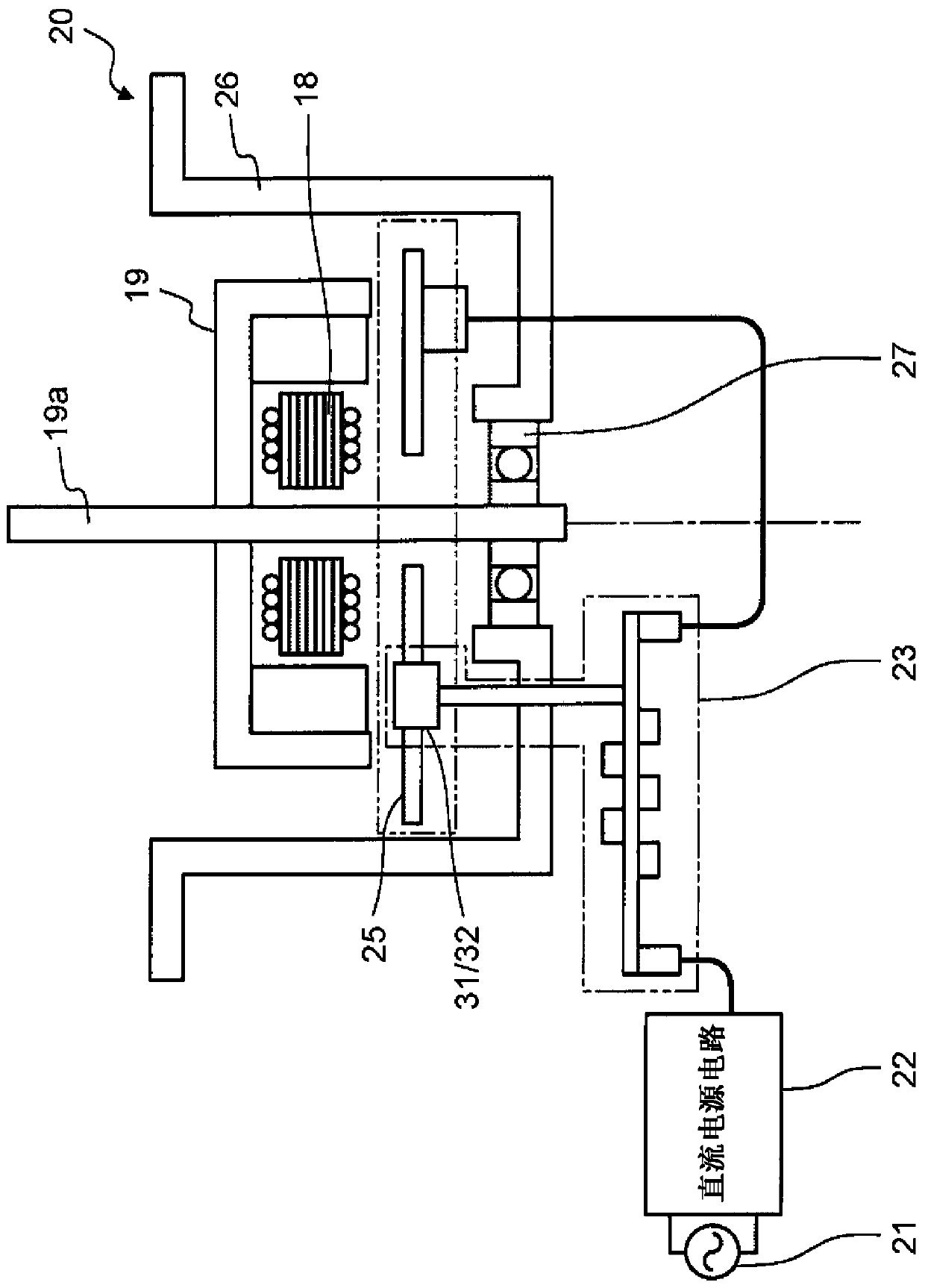

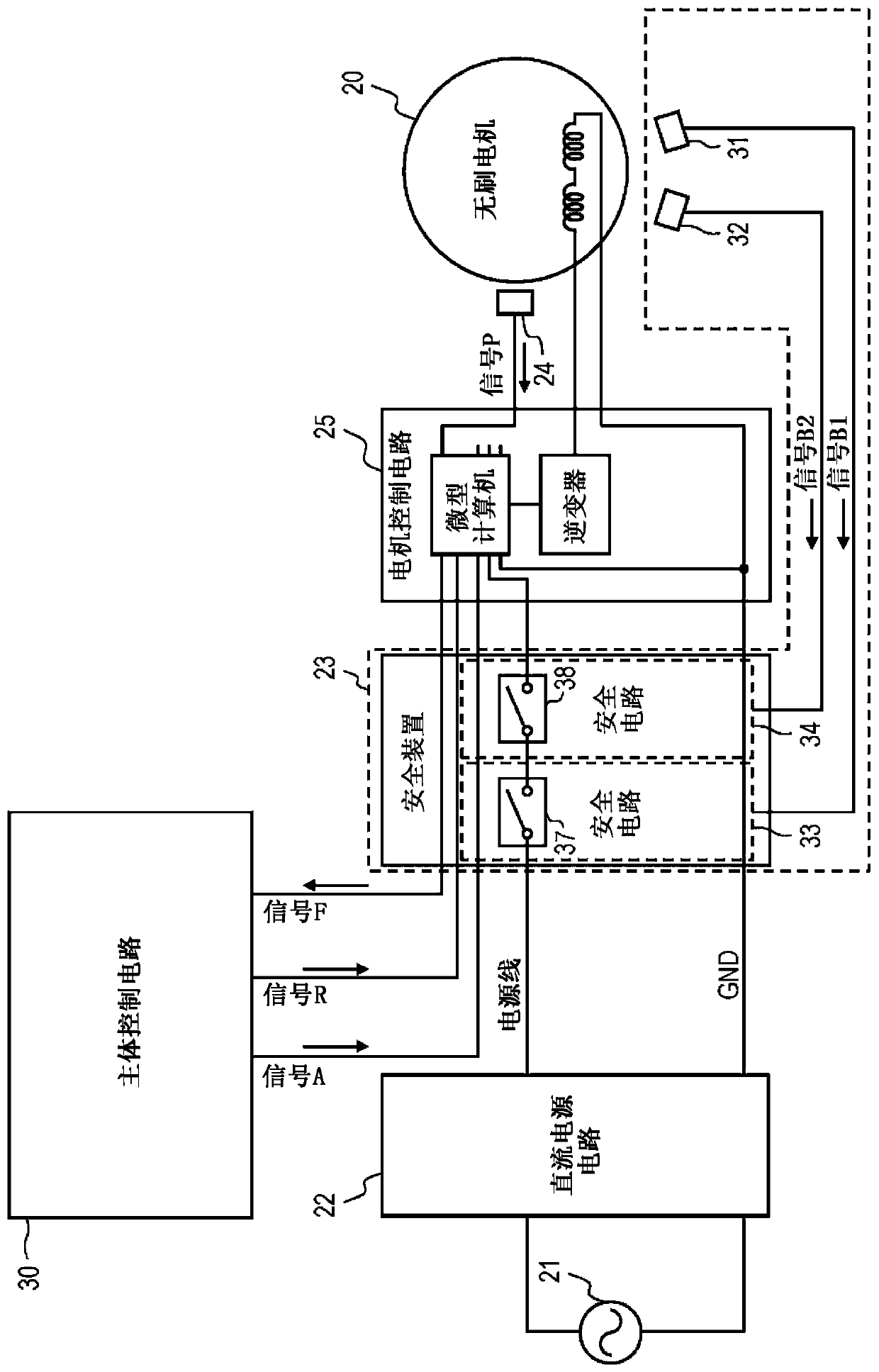

[0023] A heating cooker according to a first aspect of the present disclosure includes a heating chamber, a heating unit, a brushless motor, a main body control circuit, a DC power supply circuit, a motor control circuit, and a safety device.

[0024] The heating chamber accommodates the object to be heated. The heating unit heats the object to be heated in the heating chamber. The brushless motor is the drive source of the rotary drive mechanism included in the heating unit. The main body control circuit outputs a drive signal for the brushless motor. The DC power supply circuit provides DC power to the brushless motor. The motor control circuit controls the driving of the brushless motor according to the driving signal.

[0025] The safety device is composed of a wired logic circuit. The safety device includes: a rotation detection element configured to detect a rotation state of a rotor of the brushless motor and output a rotation detection signal; and a switch to disco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com