Battery powered industrial vehicles

A technology for industrial vehicles and batteries, applied in electric vehicles, vehicle components, vehicle energy storage, etc., can solve problems such as non-recommendation, impact on battery life, and inability to drive reach forklifts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

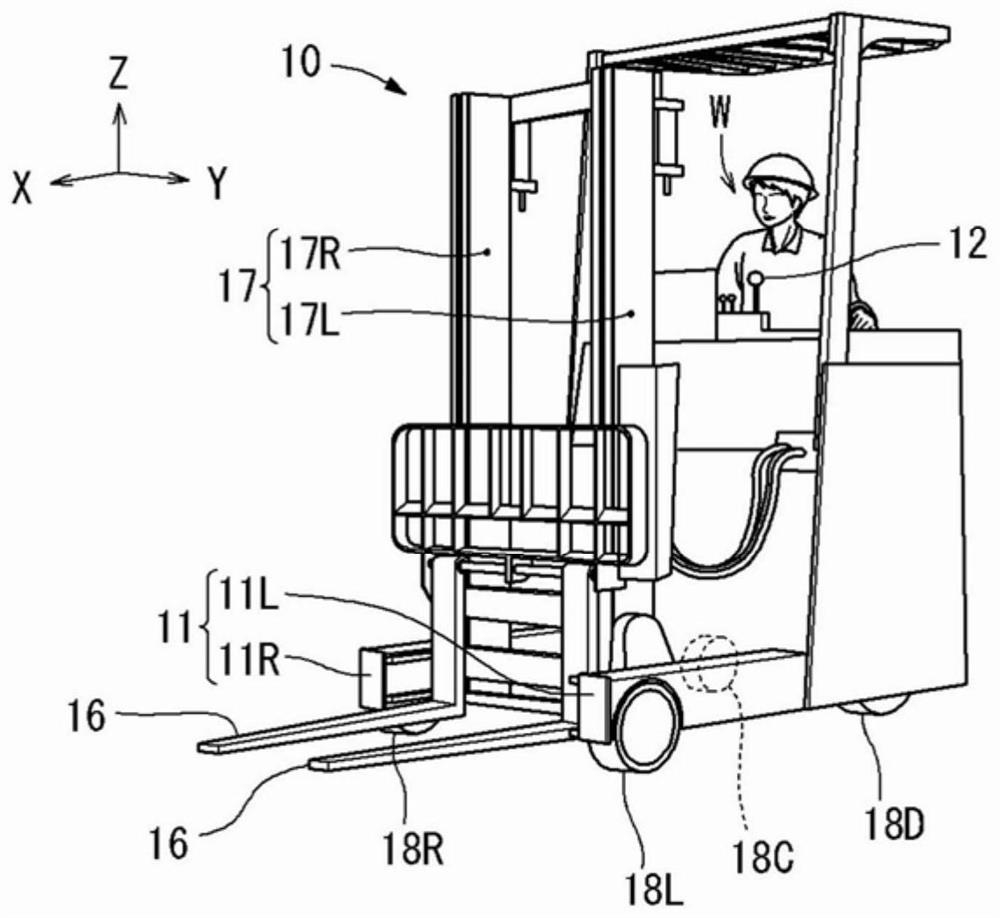

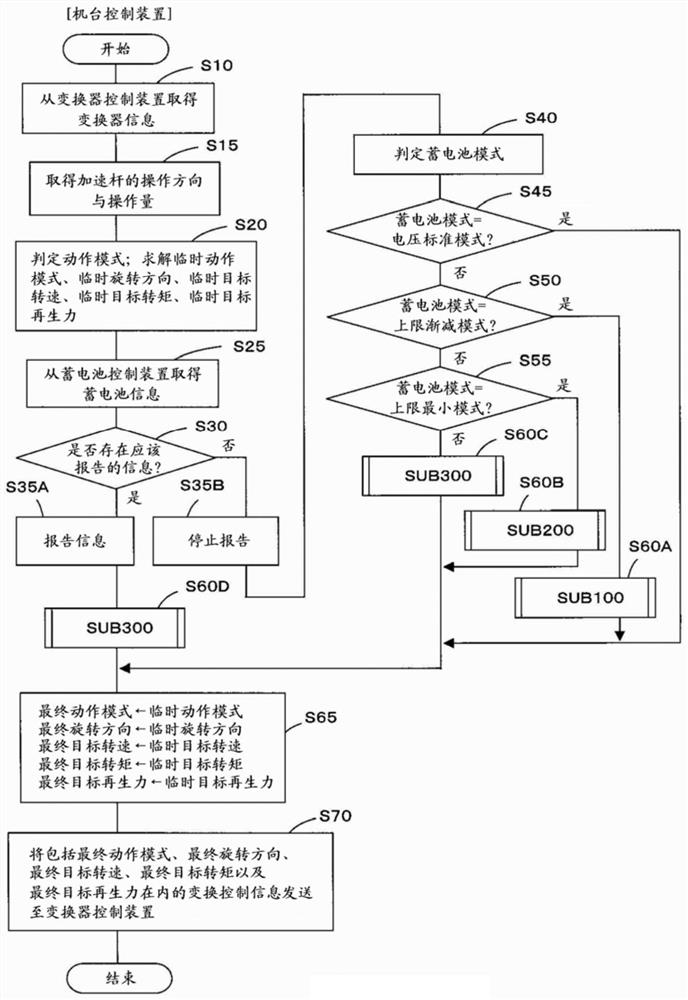

[0039] Hereinafter, the form for implementing this invention is demonstrated using drawing. also, figure 1 The appearance of the shown reach-type forklift 10 (example of the battery-type industrial vehicle) of the present invention has already been described, and thus description thereof will be omitted.

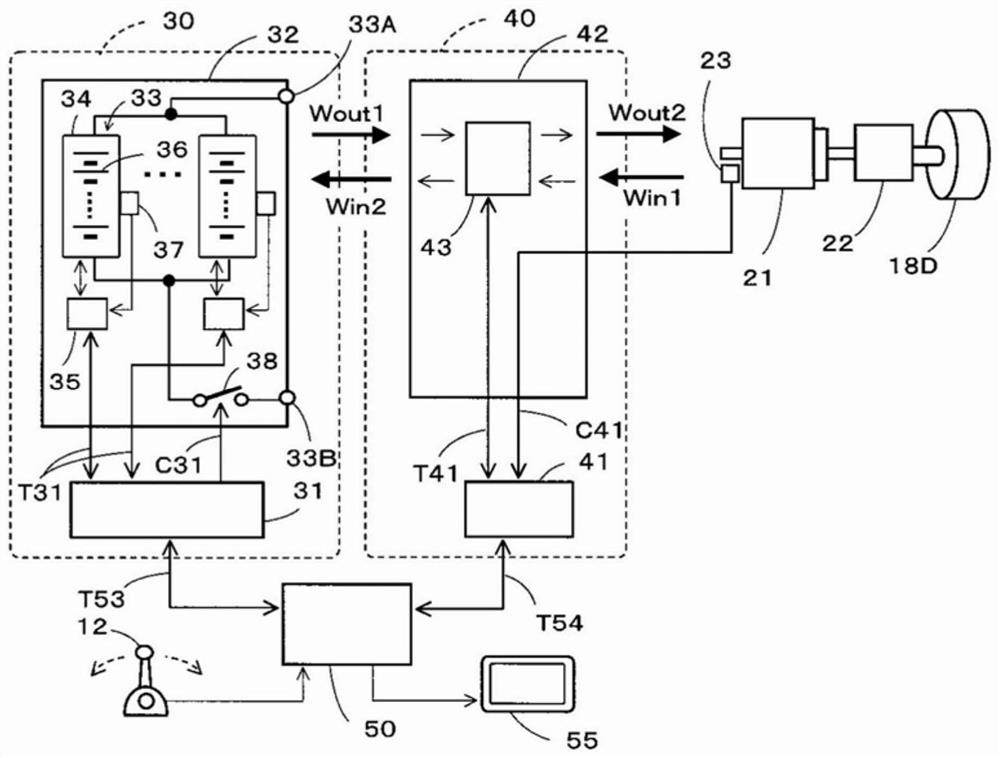

[0040] ・[The driving control system including the storage battery device 30 and the drive motor 21 ( figure 2 )]

[0041] Such as figure 2 As shown, the travel control system of the reach forklift 10 has a battery device 30, a converter device 40, a drive motor 21, a gear 22, a drive steering wheel 18D, a machine control device 50, an accelerator lever 12, a display device 55, and the like.

[0042] The battery device 30 is composed of a battery control device 31 and a battery 32 , and the battery 32 has a cutoff switch 38 , a plurality of battery module units 33 , and the like. Furthermore, each battery module unit can also have a disconnect switch 38 . The battery m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com