Robot stopping method and robot system

A robot system and robot technology, applied in the field of robot systems, can solve the problems of restarting a lot of time and energy, affecting the arm, reducer in the robot, and the processed objects and conveyed objects transported by the robot, so as to reduce the Effect of power consumption and reduction of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

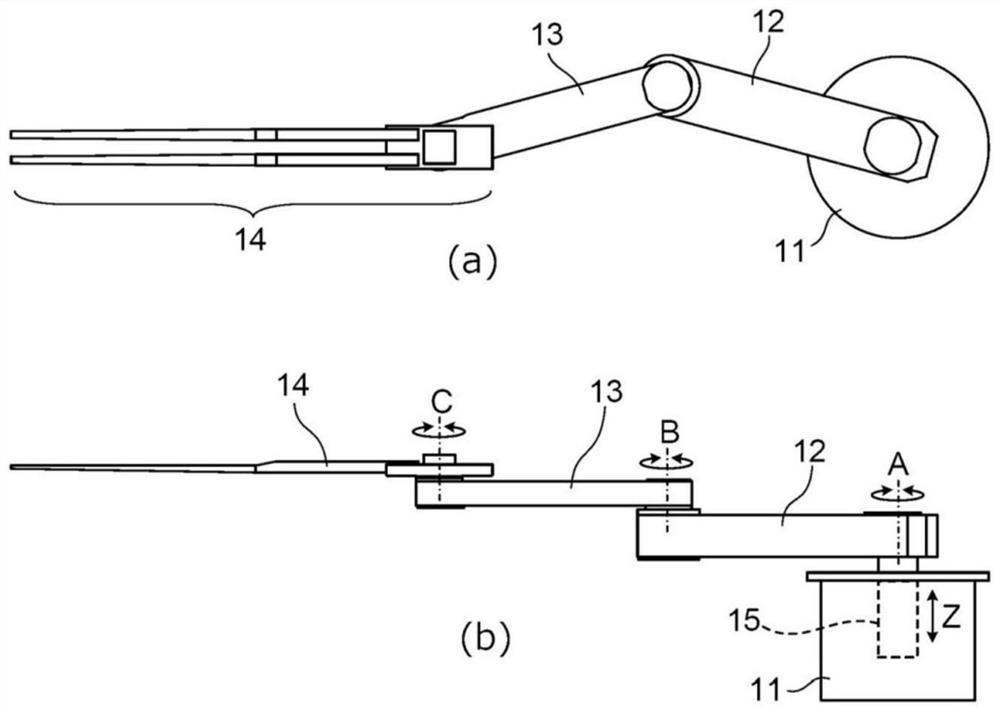

[0034] Next, embodiments of the present invention will be described with reference to the drawings. figure 1 It is a figure which shows an example of the structure of the robot included in the robot system concerning embodiment of this invention, (a) is a top view, (b) is a front view. figure 1 The shown robot is a horizontal articulated robot used for transporting semiconductor substrates, glass substrates, etc., and includes a base 11, a first arm 12 attached to the base 11, and a second arm attached to the front end of the first arm 12. 13, and the hand 14 that is installed on the front end of the second arm 13. The hand 14 is a member for holding an object to be conveyed, such as a glass substrate, and is formed in a fork shape. The first arm 12 is rotatable about an axis A relative to the base 11 , the second arm 13 is rotatable about an axis B relative to the first arm 12 , and the hand 14 is rotatable about an axis C relative to the second arm 13 . In order to enable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com